I have had this for several Months now and finally decided to put it together.

I didn't realize this is so heavy.

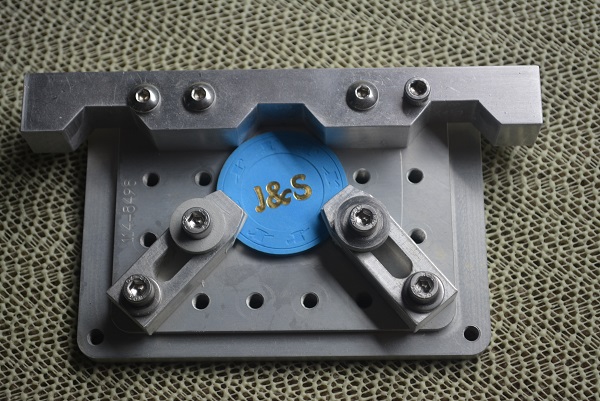

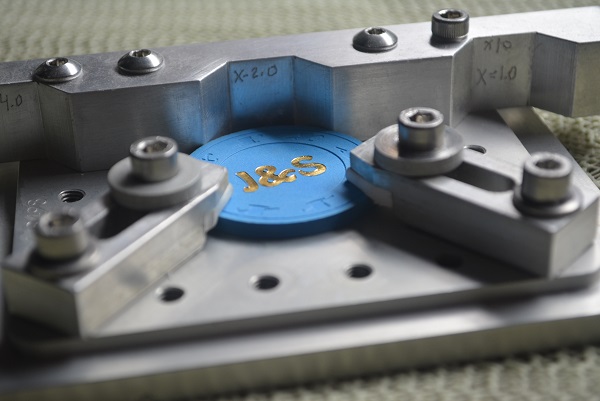

Now , to try and make a Chip Holder so I can do my 600+ HHR's to label.

The Bit is a 7/8" for the HHR's

Enjoy.....

I didn't realize this is so heavy.

Now , to try and make a Chip Holder so I can do my 600+ HHR's to label.

The Bit is a 7/8" for the HHR's

Enjoy.....

Attachments

-

100_5089.JPG150 KB · Views: 619

100_5089.JPG150 KB · Views: 619 -

100_5090.JPG118 KB · Views: 601

100_5090.JPG118 KB · Views: 601 -

100_5091.JPG135.3 KB · Views: 649

100_5091.JPG135.3 KB · Views: 649 -

100_5092.JPG143 KB · Views: 573

100_5092.JPG143 KB · Views: 573 -

100_5093.JPG153.1 KB · Views: 610

100_5093.JPG153.1 KB · Views: 610 -

100_5094.JPG161.5 KB · Views: 599

100_5094.JPG161.5 KB · Views: 599 -

100_5096.JPG166.8 KB · Views: 596

100_5096.JPG166.8 KB · Views: 596 -

100_5097.JPG115.3 KB · Views: 606

100_5097.JPG115.3 KB · Views: 606 -

100_5099.JPG110.8 KB · Views: 621

100_5099.JPG110.8 KB · Views: 621 -

100_5101.JPG72.2 KB · Views: 593

100_5101.JPG72.2 KB · Views: 593 -

100_5102.JPG80.1 KB · Views: 596

100_5102.JPG80.1 KB · Views: 596 -

100_5104.JPG93.4 KB · Views: 600

100_5104.JPG93.4 KB · Views: 600 -

100_5105.JPG89.6 KB · Views: 542

100_5105.JPG89.6 KB · Views: 542