I like to make things, but don't think I am good enough to call myself a "Maker." Thought I would create a thread to post my attempts and inevitable failures to make poker chip related things.

First, there is this post where I fall flat on my face trying to make labels at home. I think there is useful info, but the result was...well...embarrassing. Still plan to do other rounds of custom labels to learn and improve and hopefully pass along some helpful tips.

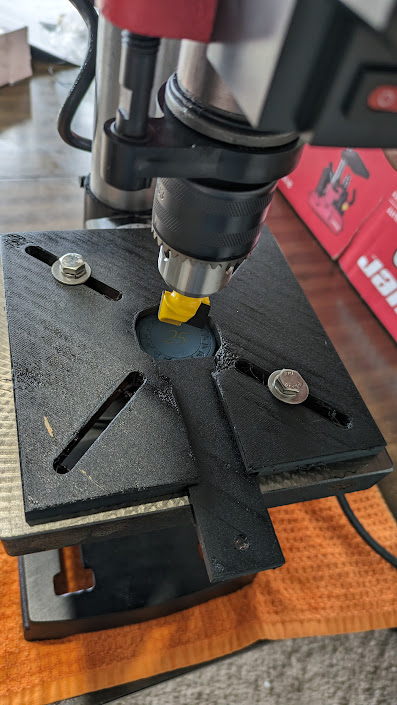

I won't have access to my CNC router or laser for a few more months, but I recently impulse-bought a cheap drill press and 7/8" surfacing bit. Here is my first attempt to dial in a a label recess mill. I expect it will take me 3 to 4 chips before I have it and then I (hope) to mill out a couple hundred in the next two weeks.

Side 1 (way to too deep and off center):

Side 2 (better depth, but a little off center still):

First, there is this post where I fall flat on my face trying to make labels at home. I think there is useful info, but the result was...well...embarrassing. Still plan to do other rounds of custom labels to learn and improve and hopefully pass along some helpful tips.

I won't have access to my CNC router or laser for a few more months, but I recently impulse-bought a cheap drill press and 7/8" surfacing bit. Here is my first attempt to dial in a a label recess mill. I expect it will take me 3 to 4 chips before I have it and then I (hope) to mill out a couple hundred in the next two weeks.

Side 1 (way to too deep and off center):

Side 2 (better depth, but a little off center still):

Last edited: