No worries. Just a shame it is not level. Would have been a sweet, easy solution. Would love to see what you come up with.Scrap. Don’t over engineer.

Edit: not trying to be an ass. Just seems really hard to make it work. GL, I’m in the middle of figuring out this same thing on my rig!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My New Drill Press, Assembly (Many Pic's) (3 Viewers)

- Thread starter RussB42

- Start date

You were right. It does not seat the chip level. Drat. Going to see what I can rig up to maybe fix this issue. Any suggestions?

View attachment 240423

That sux it didn't work out.

Last edited:

Going to try and change the orange 'pins' to to just posts and then put a small block of wood under the chip. That way the chip should sit level, be supported and the post should hold it so it won't spin. We'll see.That sux it didn't work out.I like my simple jig. I also use a pocket level when initially setting it up. If it were me, I'd want something to hard and flat below the chip. That way I'd know the chip wouldn't move or flex under the pressure of the press.

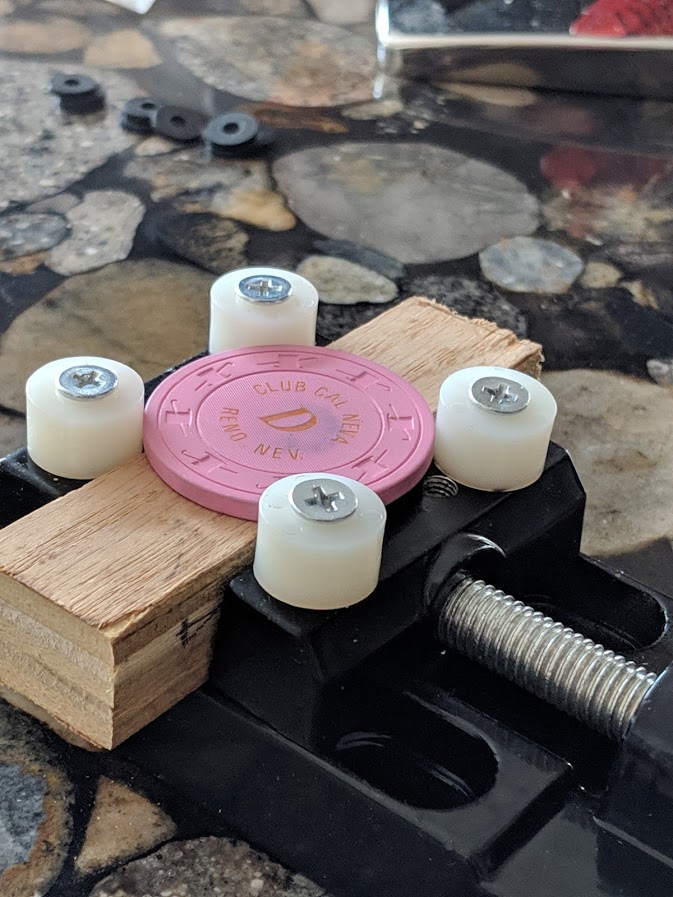

Well after a trip to home depot I came up with this. I replaced those curved orange spacers with some straight ones and I put a small block of wood below the chip for support and level. How's it look?

Well after a trip to home depot I came up with this. I replaced those curved orange spacers with some straight ones and I put a small block of wood below the chip for support and level. How's it look?

View attachment 240670

View attachment 240671

Nice! That looks like it will work much better. Where did you get the original locking mechanism?

Nice! That looks like it will work much better. Where did you get the original locking mechanism?

amazon: https://www.amazon.com/gp/product/B0753FKVMX/ref=ppx_yo_dt_b_asin_title_o00__o00_s00?ie=UTF8&psc=1

So I tried out the new rig. Worked just fine, except getting it all aligned. I had to sacrifice a few Lucky Derby's to the cause.

Amish Rabbi

Straight

it's probably worth spending a few dollars on a good vise... how much money in chips are you guys milling?

grab one of these so everything is much flatter https://www.shars.com/products/workholding/vise/3-x-2-95-lock-down-precision-milling-machine-vise

grab one of these so everything is much flatter https://www.shars.com/products/workholding/vise/3-x-2-95-lock-down-precision-milling-machine-vise

Balanar

Straight

Very interesting stuff! Watching and learning tons..

Balanar

Straight

That's what I'm kinda struggling with. I only want to go a few mm deep. Just enough that when I apply a label, it's just below the top of the chip as not to cause spinners. I've sacrificed a few chips now trying to get everything lined up just right.Back with a question: How deep do you mill when dealing with mint hotstamps?

Balanar

Straight

That's what I'm kinda struggling with. I only want to go a few mm deep. Just enough that when I apply a label, it's just below the top of the chip as not to cause spinners. I've sacrificed a few chips now trying to get everything lined up just right.

Exactly the same issue I'm facing! I have a lead on someone who has a CNC machine and is willing to work with me on getting some of these chips milled. However, he has zero experience with poker chips and if I can't give him exact measurements, this isn't gonna work.

From reading and eyeballing stuff, it appears that 1 - 1.5mm is the sweet spot which is why I would love a sample set of Gear's labels or atleast very accurate measurements from people who have those labels - both laminated and unlaminated varieties. Considering how often we use @Gear 's services, this should be stickied!

Amish Rabbi

Straight

1.5mm would be a very thick label. I’d be surprised if they are much more than .5mm

Balanar

Straight

1.5mm would be a very thick label. I’d be surprised if they are much more than .5mm

Ah sorry, I should've been clearer. Meant to say the 1mm - 1.5mm would be the sweet spot for the depth of the milling to remove the hotstamps. Of course, I might be wrong as I have not sacrificed any chips... yet.

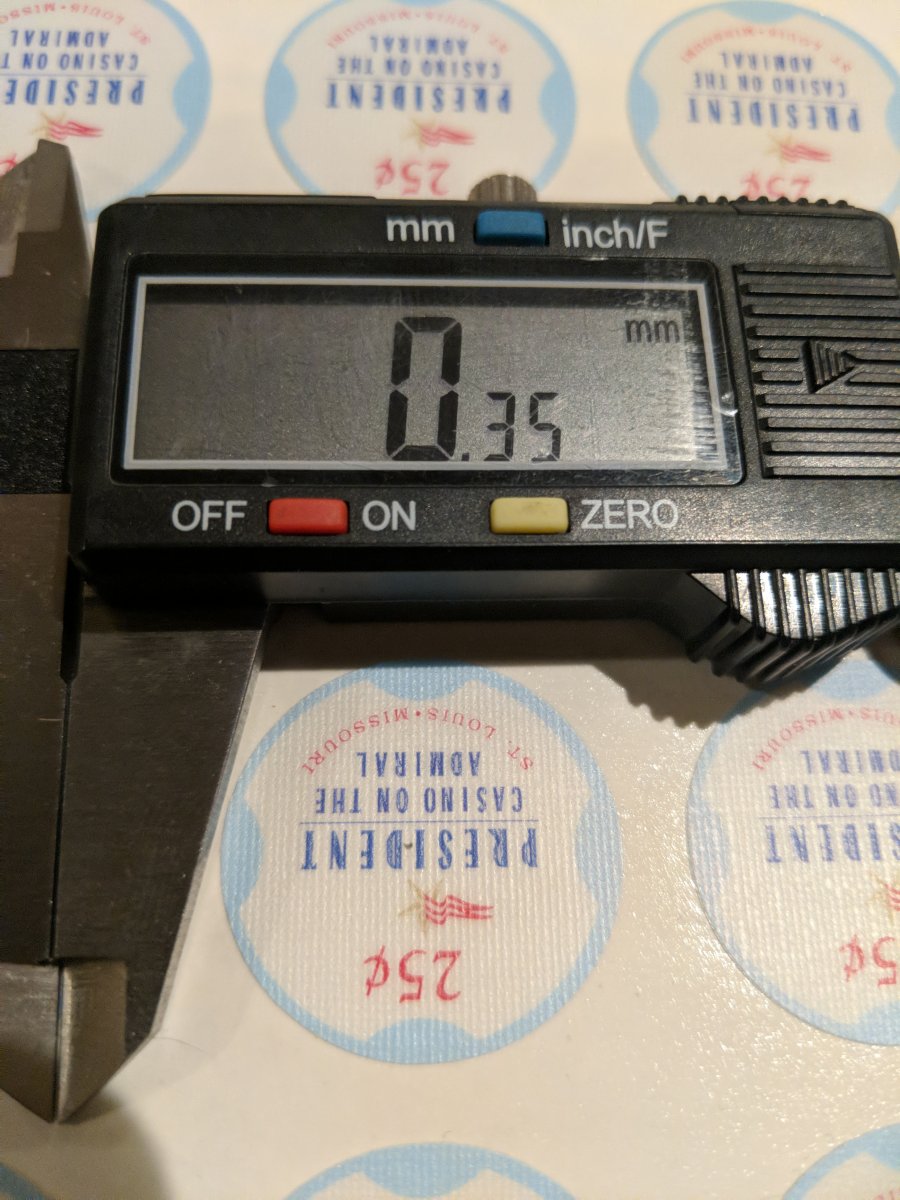

Laminated textured gear labels are about .35 mm thick.

Balanar

Straight

And the inlay depth of my PCAs is an avg of about .3 mm.

Balanar

Straight

Math was never my strong suit but would this mean ~0.6mm of milling? Add ~.3 mm of label to that and you'd end up with the ~0.3mm depth of the PCAs.

Last edited:

.35mm label recessed .3mm means .65mm milling depth. Math is fun.

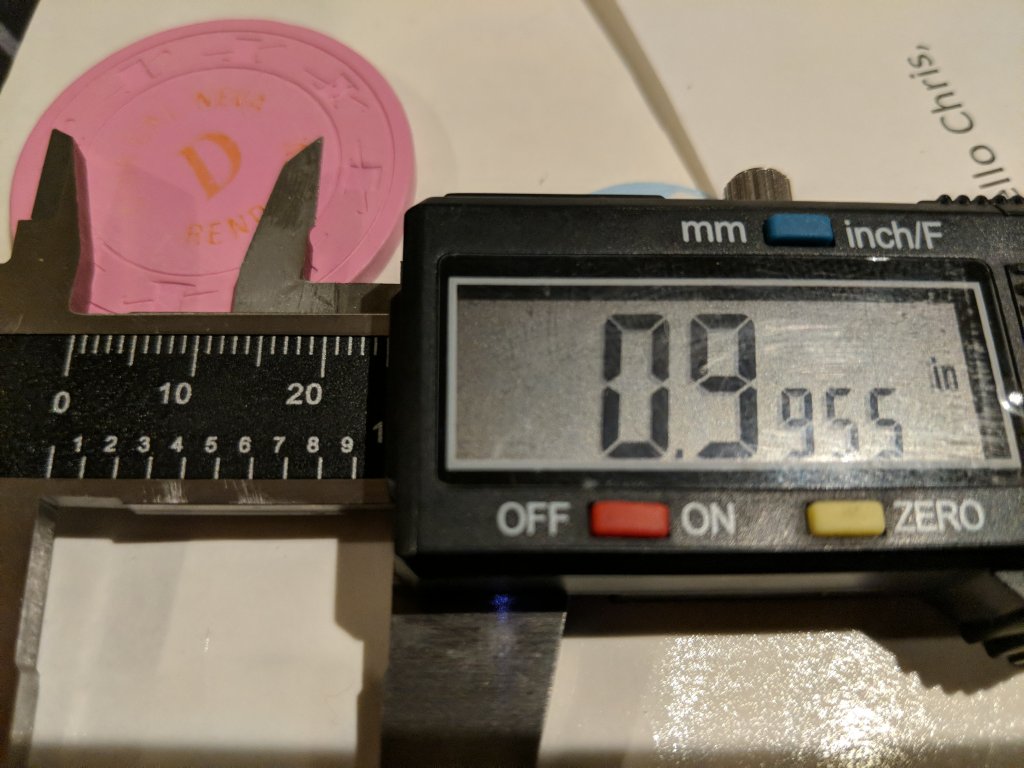

Millable area on my THCs is just shy of 1".

So I want to mill 15/16th or 31/32nds and use a 7/8" label. But I don't know how precise I'm going to get with a drill press and my jig.

I'm looking into maybe getting this CNC machine.

So I want to mill 15/16th or 31/32nds and use a 7/8" label. But I don't know how precise I'm going to get with a drill press and my jig.

I'm looking into maybe getting this CNC machine.

Balanar

Straight

Damn the imperial system. Had to Google that to get the mm measurements.

You're gonna have a fun time aligning those labels in the centre of the recess. I hope you're not particular about this kinda stuff like I am cos any misalignment would drive me insane.

You're gonna have a fun time aligning those labels in the centre of the recess. I hope you're not particular about this kinda stuff like I am cos any misalignment would drive me insane.

You want to mill barely enough to let the label sit without making a spinner. I would think 0.25mm maximum.

Does anybody mill off inlays instead of doing the manual removal method? Seems more efficient if the outcome is the same.

Some discussion of this was done before. We recommend against it. Adhesive from under the inlay will make a mess and clog up your mill. And it will burn and probably stink, too. You don't need that in your life, man.

This is why painstaking inlay removal is a thing. The original recess in the chip will be perfect for a fully laminated/textured label of the appropriate size.

LinkyBabe

Flush

https://www.pokerchipforum.com/threads/milling-an-inlay.31932/#post-584696Does anybody mill off inlays instead of doing the manual removal method? Seems more efficient if the outcome is the same.

bradiggy

Two Pair

Anybody see any issue with this bit? Price and Prime is pretty tempting but want to make sure there isn't something obviously wrong with it that I missed.

https://www.amazon.com/4-Inch-Cutti...07H8FNGGM/ref=cm_cr_arp_d_product_top?ie=UTF8

https://www.amazon.com/4-Inch-Cutti...07H8FNGGM/ref=cm_cr_arp_d_product_top?ie=UTF8

Anybody see any issue with this bit? Price and Prime is pretty tempting but want to make sure there isn't something obviously wrong with it that I missed.

https://www.amazon.com/4-Inch-Cutti...07H8FNGGM/ref=cm_cr_arp_d_product_top?ie=UTF8

I have that bit. Mine appears to not be 100% flat. It has a slight bevel in the middle when used so to completely remove hot stamp, you have to mill deeper. YMMV.

(ignore that the milling is not centered)

Similar threads

- Replies

- 21

- Views

- 884

- Replies

- 18

- Views

- 746

- Replies

- 27

- Views

- 924