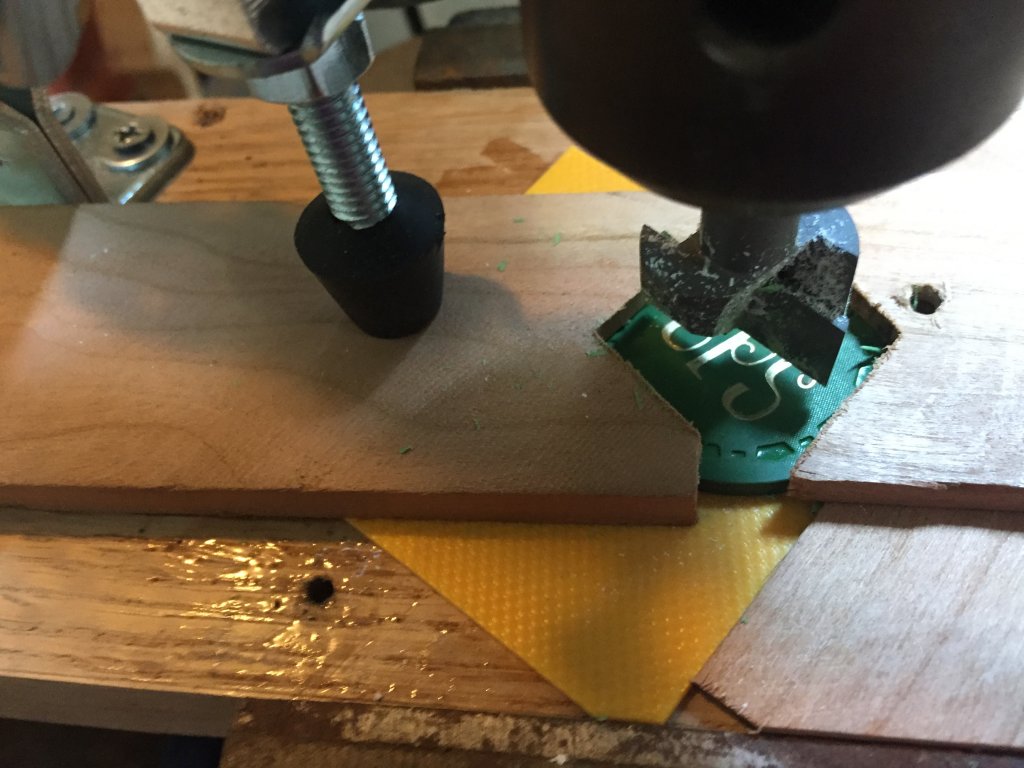

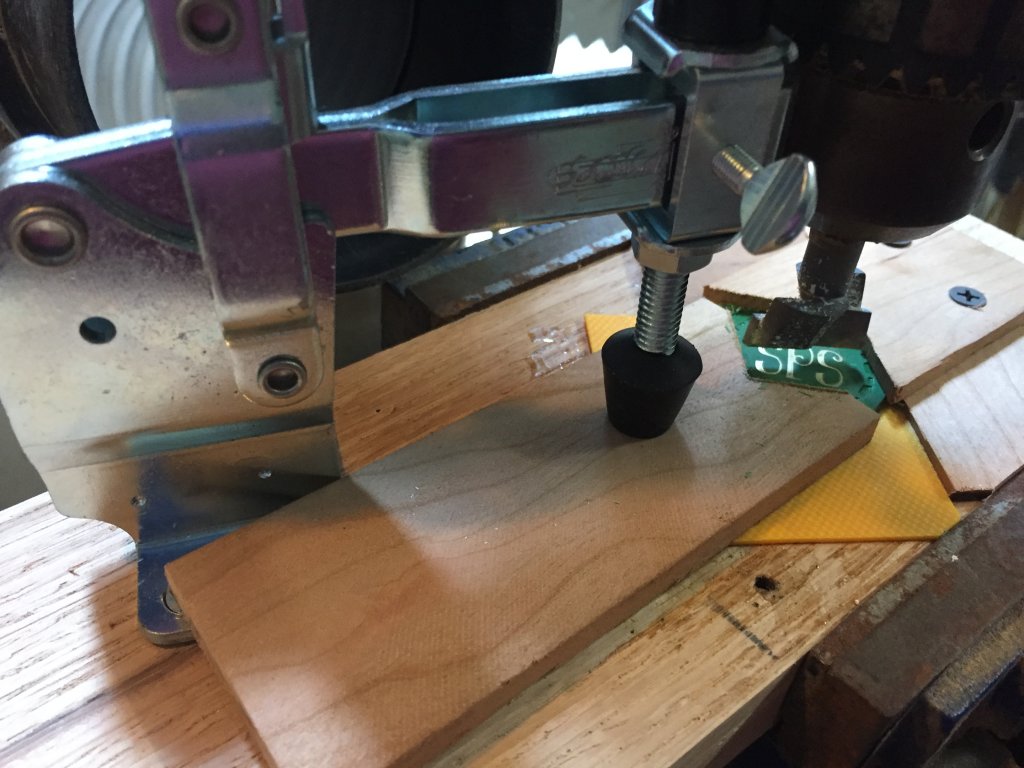

This was the set up eventual got to work. The biggest challenge turned out getting a non spin surface that didn't depress the chip uneven when securely clamped.

I ended up using one of those rubber grip things you use to open jars. It was like 2 bucks.

I ended up using one of those rubber grip things you use to open jars. It was like 2 bucks.