First, I want to thank all the other people that posted their poker table builds with detailed pictures, it was a huge help in deciding what to do and how to do it.

This is my first poker table build and the reason I went with round is because the room it will be in, oval just would not work. Going 60” round was a must because we always have 8 people playing a cash game. I went with a track because that is want most people in my group prefer, however maybe in the future I will go full custom felt, those look pretty nice on this forum. I hope this post helps the next person on their table build, feel free to ask any questions, I definitely still have a few of my own on how to get better next time.

List of materials used:

Step 1: Design

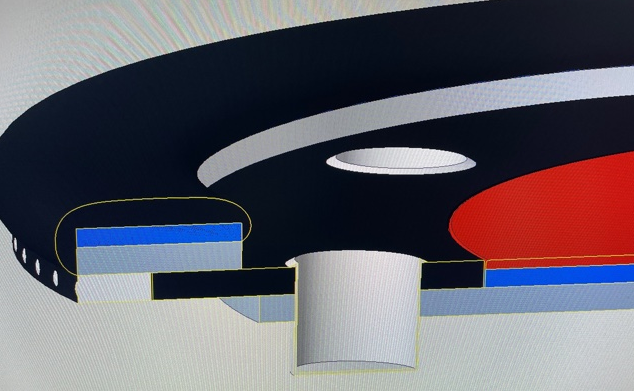

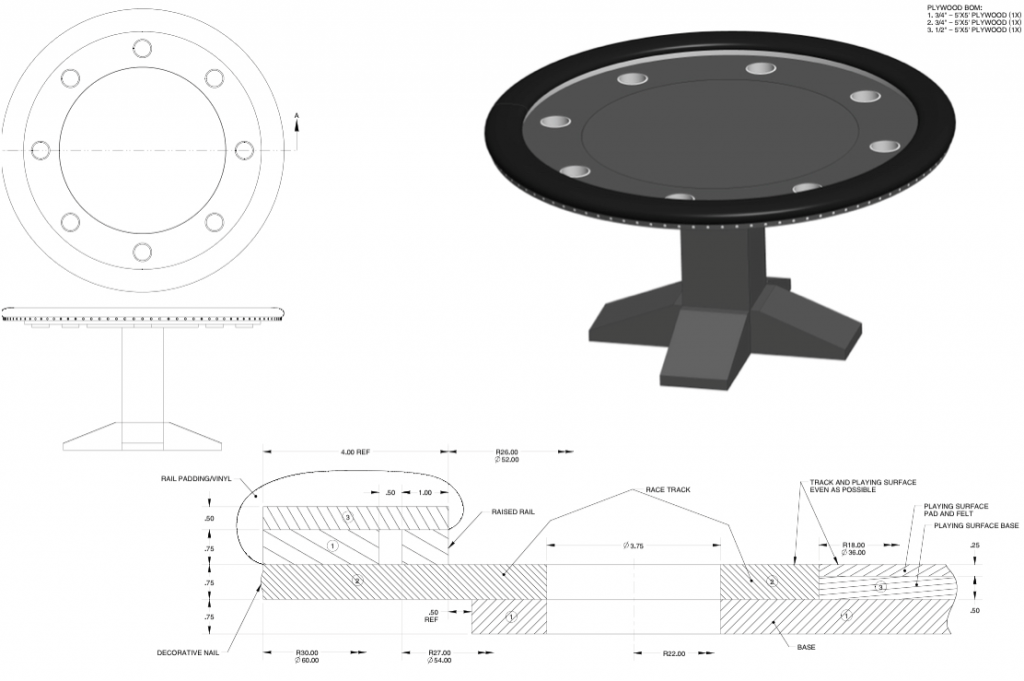

I am a mechanical designer, so I used my CAD program to build my poker table idea in 3D and then layout in 2D with some dimension to follow. I wanted to have a raised rail because I really like the suited diffusers @T_Chan offers. I did not want to go too tall with the raised rail because of comfort, so I went with 3/4" tall. I was originally going to just have the raised suited diffusers with a black background, but I did a design change in the middle of the build (not reflected in the drawing) and added lights. I just could not pass up trying to add lights since it looks so nice on other people builds on this forum.

Step 2: The Pedestal

I was debating back and forth on foldable legs for portability vs a pedestal and I am glad I went with the pedestal; it just gives a professional permanent feel. We will not be moving the table but if we do, I designed it so we can unbolt the table top off with ease using t-nuts. I found this online at Unfinished Furniture of Wilmington. I think worth the extra cost. All I had to do was stain/poly it.

Step 3 – Cutting the Plywood

Luckily, I was able to find 5’x5’ plywood about 45min from me. I definitely was not going to join 2 pieces of plywood together with my lack of woodworking skills. I put the 3 sheets together and clamped them so I can get a perfect round cut of 60” on all three sheets. I drilled a center hole through all three so they can all line up and have the same center point.

Step 4 – Cup Holder Cuts

Cutting out the holes for the cup holders in the track. I used a 3-1/2” hole saw. I actually like what other people did with cup holders in the rail but this being my first build that seemed a little aggressive this time around.

To Be Continued.....ran the limit on posting pics in one post.

This is my first poker table build and the reason I went with round is because the room it will be in, oval just would not work. Going 60” round was a must because we always have 8 people playing a cash game. I went with a track because that is want most people in my group prefer, however maybe in the future I will go full custom felt, those look pretty nice on this forum. I hope this post helps the next person on their table build, feel free to ask any questions, I definitely still have a few of my own on how to get better next time.

List of materials used:

Material | Cost (tax/shipping included) | Source |

| (2X) 3/4" 5’x5’ Russian Birch Plywood | $104 | Middle TN Lumber, Dickson |

| 1/2" 5’x5’ Plywood | $24 | Middle TN Lumber, Dickson |

| 1" Solid Charcoal Firm Foam - 80"x72" | $52 | https://www.thefoamfactory.com/ |

| 61" Wide Rail Vinyl | $72 | https://www.justpokersupplies.com/p...-black-two-way-stretch-sold-per-running-foot/ |

| 2-A Density Volara - 1/4" Thick Closed Cell Foam (WHITE) (2 yards) | $22 | www.yourautotrim.com |

| Nickel Plated "Chrome" Decorative Nail Head (Individual) | $11 | www.yourautotrim.com |

| Osborne Quick Nailer | $9 | www.yourautotrim.com |

| Holdem Casino Suited Cloth "Blackberry" (2 Yards) | $40 | www.yourautotrim.com |

| Pro Foam and Fabric Spray Adhesive | $7 | www.yourautotrim.com |

| (8X) Stainless Steel Jumbo Drop In Holder | $60 | www.casinosupply.com |

| T-10B Java Table Base for Round Table Tops | $200 | https://www.unfinishedfurnitureofwilmington.com/ |

| Raised Rail Diffuser | $144 | https://www.chanmanpokertables.com/ |

| T-nuts and Bolts | $53 | www.mcmastercarr.com |

| 3/4" 2x2 Plywood for Base | $13 | Lowes |

| Staining/Poly Materials | $117 | Home Depot/Lowes |

| (3X) Led Strip Lights Battery Powered | $39 | https://www.amazon.com/gp/product/B07QK45LZZ/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1 |

Step 1: Design

I am a mechanical designer, so I used my CAD program to build my poker table idea in 3D and then layout in 2D with some dimension to follow. I wanted to have a raised rail because I really like the suited diffusers @T_Chan offers. I did not want to go too tall with the raised rail because of comfort, so I went with 3/4" tall. I was originally going to just have the raised suited diffusers with a black background, but I did a design change in the middle of the build (not reflected in the drawing) and added lights. I just could not pass up trying to add lights since it looks so nice on other people builds on this forum.

Step 2: The Pedestal

I was debating back and forth on foldable legs for portability vs a pedestal and I am glad I went with the pedestal; it just gives a professional permanent feel. We will not be moving the table but if we do, I designed it so we can unbolt the table top off with ease using t-nuts. I found this online at Unfinished Furniture of Wilmington. I think worth the extra cost. All I had to do was stain/poly it.

Step 3 – Cutting the Plywood

Luckily, I was able to find 5’x5’ plywood about 45min from me. I definitely was not going to join 2 pieces of plywood together with my lack of woodworking skills. I put the 3 sheets together and clamped them so I can get a perfect round cut of 60” on all three sheets. I drilled a center hole through all three so they can all line up and have the same center point.

- I found this router at Lowes on sale. It was perfect for what I needed it for. I know routers can be expensive and I will probably only use it to make tables. Make sure if you go with a router you get a plunge base. I used a 1/2" router bit for all the cuts

- I bought the Milescraft CircleGuideKit (Router Jig, $48) to make the circles cuts but I did have to make my own jig to be able to cut the 60” diameter and another diameter since the Milescraft jig only goes to 52” diameter. I definitely recommend the for all other cuts 52” diameter for ease and accuracy.

- I made rookie mistake by cutting this in my garage, the saw dust got everywhere and on everything. I moved the operation outside to finish cutting the other pieces out.

Step 4 – Cup Holder Cuts

Cutting out the holes for the cup holders in the track. I used a 3-1/2” hole saw. I actually like what other people did with cup holders in the rail but this being my first build that seemed a little aggressive this time around.

To Be Continued.....ran the limit on posting pics in one post.