Question for the keg & wet bars guys @CraigT78 @Old State

How did you guys run your beer lines from the kegerator to the bar top mounted tower? I've built several kegerators but those all had the tower directly mounted to the top of the mini fridge, so this is slightly new territory for me. Here's what I was thinking of doing:

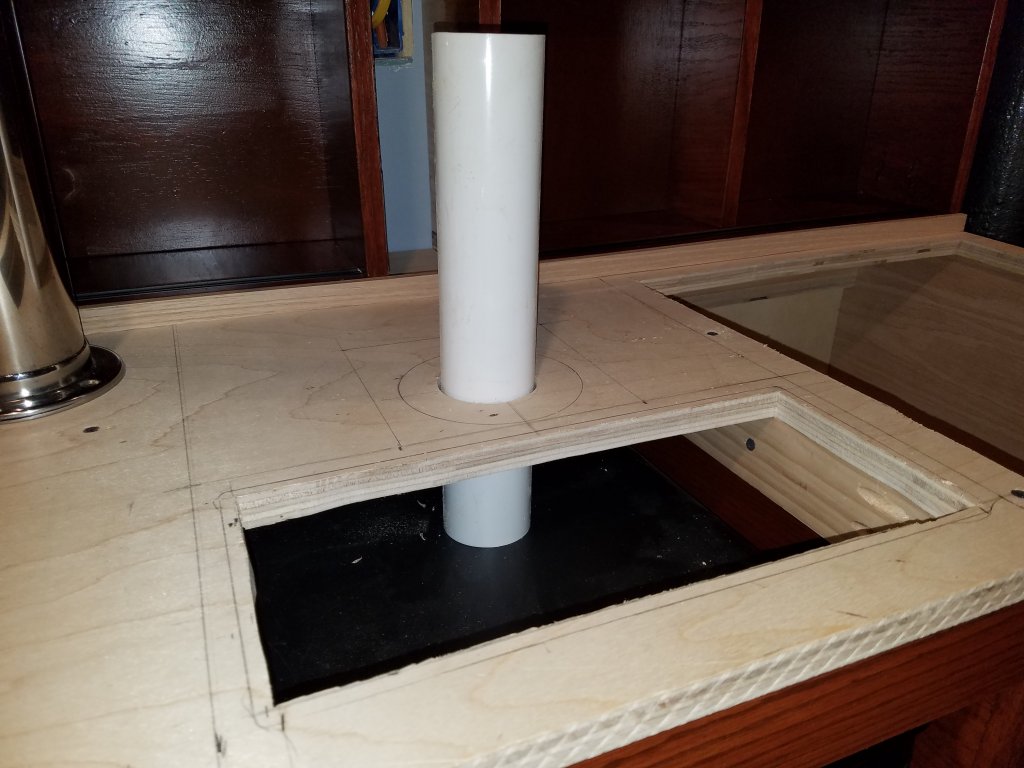

Cut outs for drip tray and tower lines, the top of the mini fridge is about 4" below the counter surface:

I found a piece of pvc pipe that will fit just inside tower, I was thinking if running this through the hole in the counter, down to the hole (not there yet) in the top of the fridge, putting a little putty on the end of the pipe to help seal it.

I don't plan on adding a fan to force chill the tower but I thought this would work to keep everything relatively sealed. Any thoughts, feedback or other recommendations?

How did you guys run your beer lines from the kegerator to the bar top mounted tower? I've built several kegerators but those all had the tower directly mounted to the top of the mini fridge, so this is slightly new territory for me. Here's what I was thinking of doing:

Cut outs for drip tray and tower lines, the top of the mini fridge is about 4" below the counter surface:

I found a piece of pvc pipe that will fit just inside tower, I was thinking if running this through the hole in the counter, down to the hole (not there yet) in the top of the fridge, putting a little putty on the end of the pipe to help seal it.

I don't plan on adding a fan to force chill the tower but I thought this would work to keep everything relatively sealed. Any thoughts, feedback or other recommendations?