Knipedrums

Sitting Out

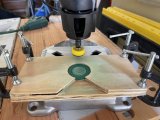

Someone in a thread I was following suggested purchasing 1” sanding pad for dremel and using it to sand down a chip instead of milling. I purchased a few of these handy pads and am testing it on some cheap super diamonds. The super diamonds need some relief if I ever hope to label them. The chips feel amazing but labels will not stay unless they are mad or be smoother in the center.

unfortunately my dremel shit the bed and I need to get some new brushes.

I am also going to mill these down with my drill press to see which works better. Just after a few passes I can see that the dremel workstation will take many passes to get the label area smooth. But if that is all you have it will work.

i will continue to work on this side project for fun.

Thanks for all the ideas, this is a great forum. TK

unfortunately my dremel shit the bed and I need to get some new brushes.

I am also going to mill these down with my drill press to see which works better. Just after a few passes I can see that the dremel workstation will take many passes to get the label area smooth. But if that is all you have it will work.

i will continue to work on this side project for fun.

Thanks for all the ideas, this is a great forum. TK