@ekricketWho is an engineer up in here that can lead me to thermoplastics melting point chart OR just tell me what thermoplastics have lower melting points...

-

PCF is an Amazon Associate and an eBay Partner. If you make a purchase through one of our links, we may earn a commission at no extra cost to you. Thank you for your support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So it begins aka poker chip making quest (1 Viewer)

- Thread starter Grandmasturkey

- Start date

CrazyEddie

Full House

this is pure awesome

Grandmasturkey

Flush

First hot stampings for the spooky tree haunted casino!

So fun! haha I love itFirst hot stampings for the spooky tree haunted casino!

View attachment 701801View attachment 701802View attachment 701803

ekricket

Royal Flush

Feels like Trogdor should be in this setFirst hot stampings for the spooky tree haunted casino!

View attachment 701801View attachment 701802View attachment 701803

Grandmasturkey

Flush

The email the email I hope it's from a femaleFeels like Trogdor should be in this set

Colquhoun

4 of a Kind

Hot stamping milled chips?First hot stampings for the spooky tree haunted casino!

View attachment 701801View attachment 701802View attachment 701803

Well played.

Grandmasturkey

Flush

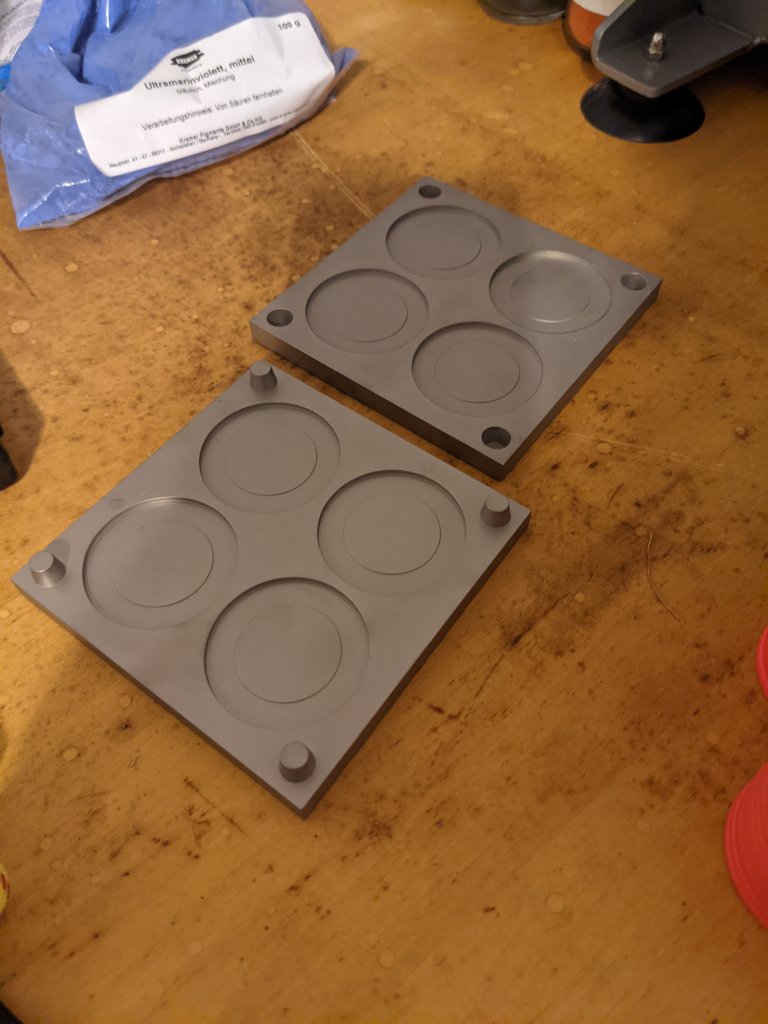

Okay so. Ran into a problem with the other mold because it was TOO FAT to fit into my hydraulic press...no love for big girls.

Anyways, ordered a new steel bead blasted mold:

Anyways, gonna start seriously trying to make some 10g chips that stay together next week. Will be updating this thread more frequently now that I have the mold I'm going to use.

Again, stay tuned.

Anyways, ordered a new steel bead blasted mold:

Anyways, gonna start seriously trying to make some 10g chips that stay together next week. Will be updating this thread more frequently now that I have the mold I'm going to use.

Again, stay tuned.

CrazyEddie

Full House

Time to bake some cookies!

ekricket

Royal Flush

Curious what a super diamond would do in there, if you could remold it even enough to make a difference.Okay so. Ran into a problem with the other mold because it was TOO FAT to fit into my hydraulic press...no love for big girls.

Anyways, ordered a new steel bead blasted mold:

View attachment 721794

Anyways, gonna start seriously trying to make some 10g chips that stay together next week. Will be updating this thread more frequently now that I have the mold I'm going to use.

Again, stay tuned.

Grandmasturkey

Flush

Today I made this!

There are obviously a litany of problems but happy to have made something that mildly resembles a poker chip. Its birth weight was around 6g so very underweight.

There are obviously a litany of problems but happy to have made something that mildly resembles a poker chip. Its birth weight was around 6g so very underweight.

You get 100 extra points from me on top of the nice chip creation, for the nice use of the Greek word "litany".

Originally a repetitive prayer (what Buddhists would call "mantra"), it has come to mean the parading of holy icons in public, in modern Greek. The ancient root of the word is related to seeking God's mercy.

Originally a repetitive prayer (what Buddhists would call "mantra"), it has come to mean the parading of holy icons in public, in modern Greek. The ancient root of the word is related to seeking God's mercy.

Today I made this!

View attachment 724943

View attachment 724944View attachment 724945View attachment 724947

There are obviously a litany of problems but happy to have made something that mildly resembles a poker chip. Its birth weight was around 6g so very underweight.

looks cool, but it seems like you made the mold to exactly 39mm? i.e. you left no room for error to lathe off the rough edges and maintain 39mm.

ekricket

Royal Flush

Pretty sure it’s just a mold to test clays, not the final mold to press them. He’s going to get the clay right first, then build all the other 99 steps. I tried to get him to build a whole factory before even getting any clay but he’s bound and determined to do it one step at a time.looks cool, but it seems like you made the mold to exactly 39mm? i.e. you left no room for error to lathe off the rough edges and maintain 39mm.

Pretty sure it’s just a mold to test clays, not the final mold to press them. He’s going to get the clay right first, then build all the other 99 steps. I tried to get him to build a whole factory before even getting any clay but he’s bound and determined to do it one step at a time.

i sure do appreciate a good labor of love.

wask

Sitting Out

There a special table with red ropes surrounding it in heaven for people like you.

Fascinating project. Keep em coming.

Also the « spooky tree haunted casino » wins best logo and casino name ever for me.

Fascinating project. Keep em coming.

Also the « spooky tree haunted casino » wins best logo and casino name ever for me.

Use lead-backed adhesive labels. Gold inserts if you can afford it.Its birth weight was around 6g so very underweight.

CrazyEddie

Full House

Just add a metal slug! That's what Paulson did, after all.

https://www.pokerchipforum.com/thre...ll-crowns-w-lattice.64817/page-3#post-1294395

https://www.pokerchipforum.com/thre...ll-crowns-w-lattice.64817/page-3#post-1294395

Grandmasturkey

Flush

Hello everyone!!

I am trying to hot stamp some RHCs and I was hoping to get your guys advice:

This is what is happening:

As you can see the middle of the stamp is not stamping. I assume this is because there is a slight concavity on the middle of the chip because of the glue that was there.

Im looking for any and all suggestions about how to even out the surface of the chip in order to make the stamp have contact with the entire face!

Any help would be appreciated!

I am trying to hot stamp some RHCs and I was hoping to get your guys advice:

This is what is happening:

As you can see the middle of the stamp is not stamping. I assume this is because there is a slight concavity on the middle of the chip because of the glue that was there.

Im looking for any and all suggestions about how to even out the surface of the chip in order to make the stamp have contact with the entire face!

Any help would be appreciated!

Grandmasturkey

Flush

I should mention I have tried a light sand with a micro sander and hand sanding without success

Amazing work @Grandmasturkey! I love reading about your progress. I wonder if it'd be possible to flatten just the recess with a wooden clamp using smaller diameter ceramic blanks (or some other smooth flat disc with the same diameter as the recess). I'd worry about the outer edge of the chip warping in that case but it might be worth a shot. If you could find washers with the right inner/outer diameters to cover just the part of the chip with the mold, maybe you can press them both at the same time to avoid outer edge warping while still flattening the middle recess.

Edit: thinking about this, I bet a more aggressive sanding of the middle (or milling) would probably be more effective

Edit: thinking about this, I bet a more aggressive sanding of the middle (or milling) would probably be more effective

Last edited:

Grandmasturkey

Flush

Yeah like maybe mill them like <1mm just to make everything flush?Amazing work @Grandmasturkey! I love reading about your progress. I wonder if it'd be possible to flatten just the recess with a wooden clamp using smaller diameter ceramic blanks (or some other smooth flat disc with the same diameter as the recess). I'd worry about the outer edge of the chip warping in that case but it might be worth a shot. If you could find washers with the right inner/outer diameters to cover just the part of the chip with the mold, maybe you can press them both at the same time to avoid outer edge warping while still flattening the middle recess.

Edit: thinking about this, I bet a more aggressive sanding of the middle (or milling) would probably be more effective

Grandmasturkey

Flush

Attention attention update:

I have figured out a way to flatten the center of the chips:

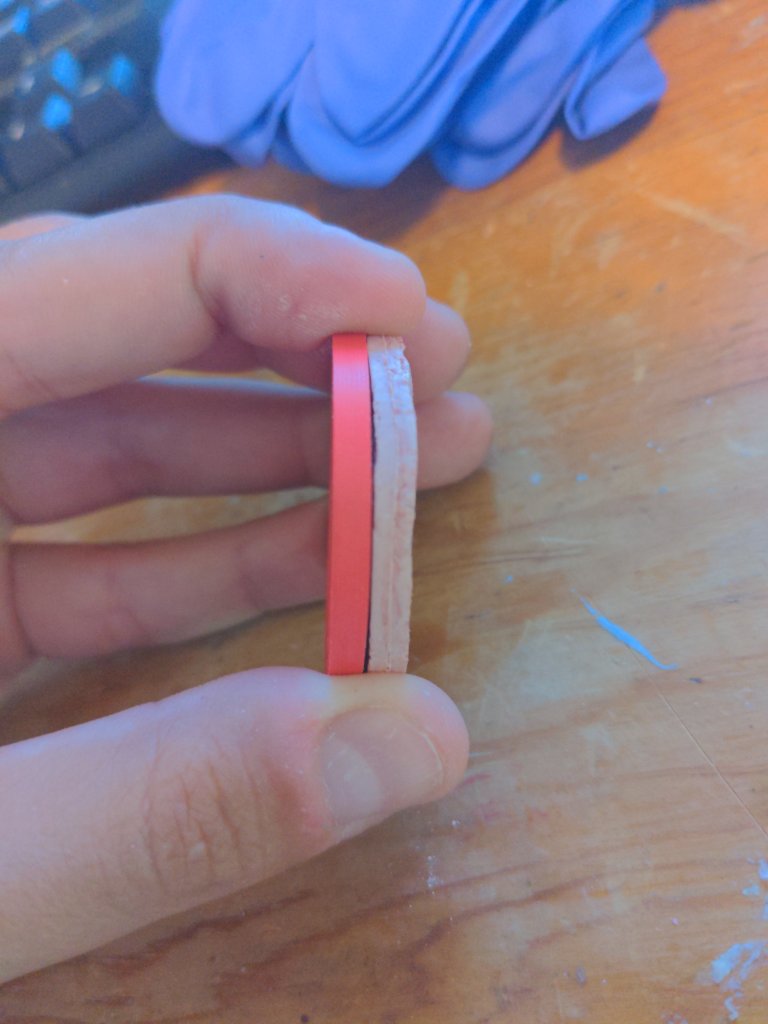

This is a 1" stamping blank

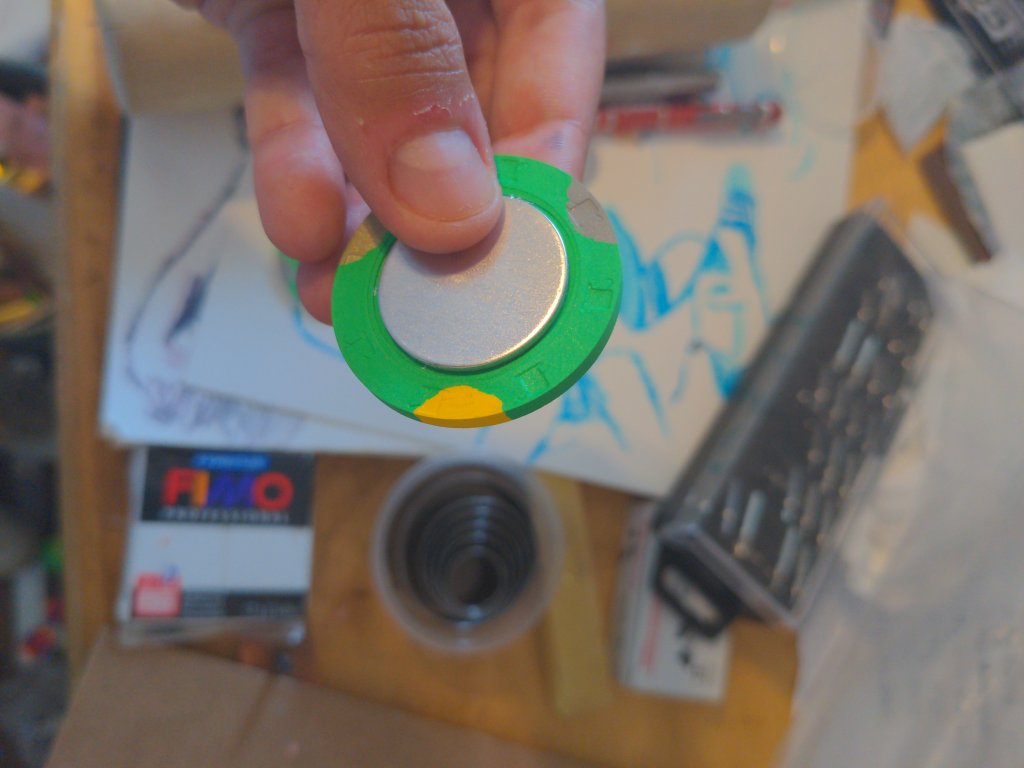

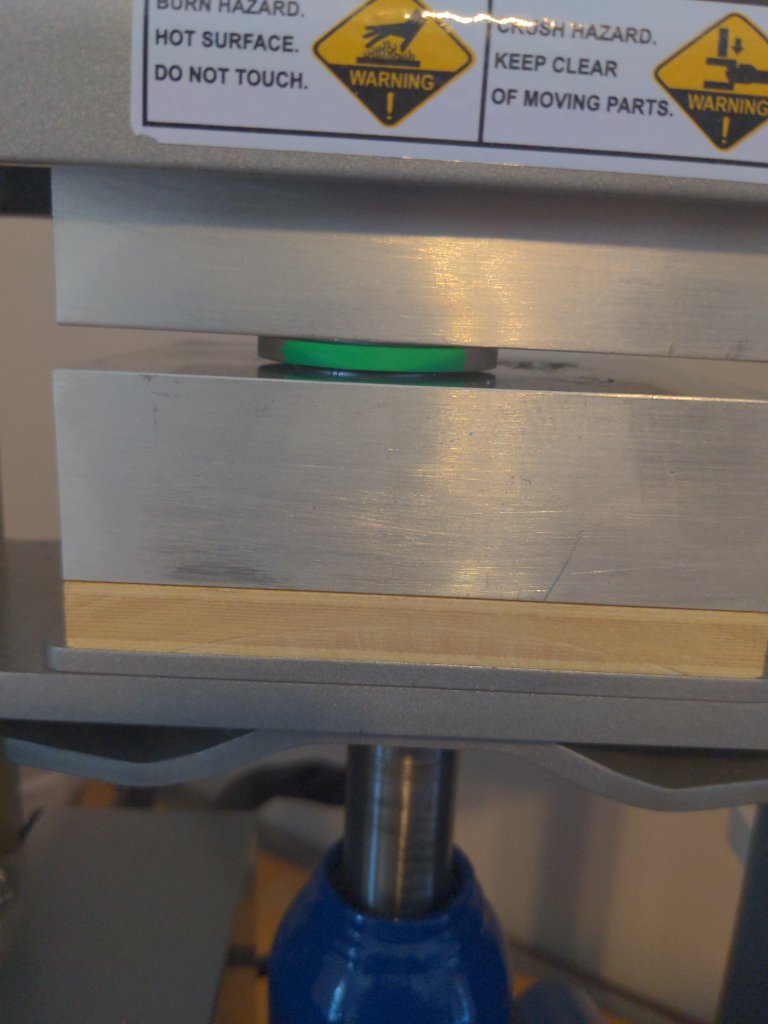

I place one of these babies on each side of the chip in my hydraulic heated press, like so:

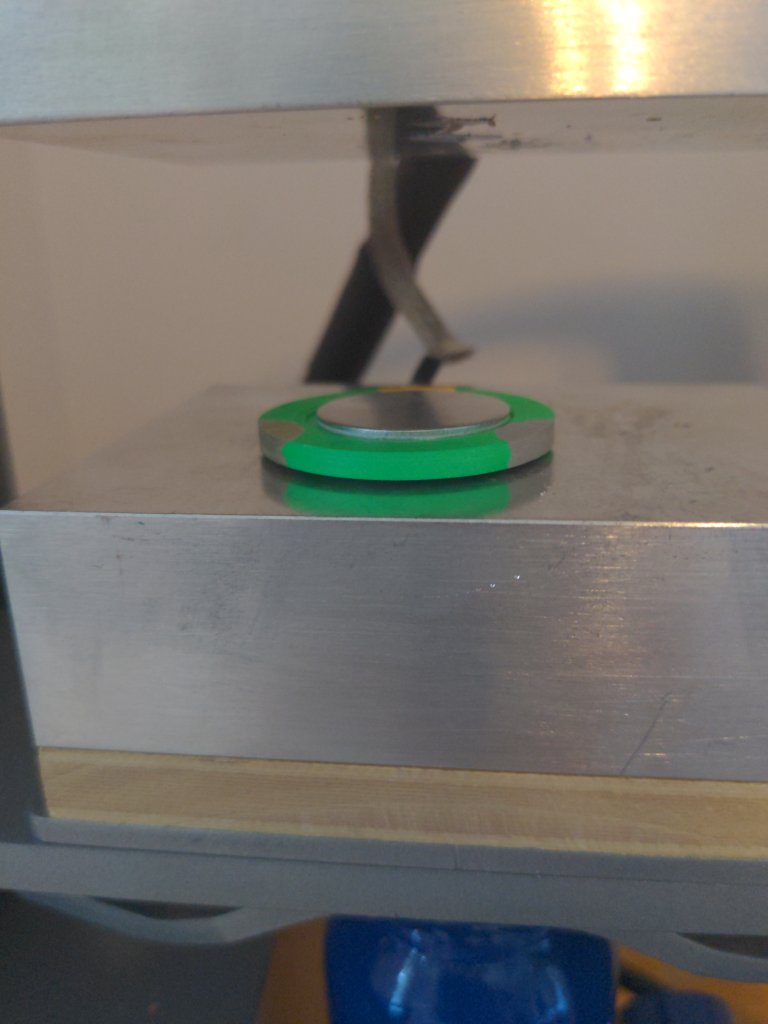

Then press it for about a minute at a reasonable temp:

Then it comes out flattened and smooth in the middle:

Then you can stamp!

I have figured out a way to flatten the center of the chips:

This is a 1" stamping blank

I place one of these babies on each side of the chip in my hydraulic heated press, like so:

Then press it for about a minute at a reasonable temp:

Then it comes out flattened and smooth in the middle:

Then you can stamp!

Attention attention update:

I have figured out a way to flatten the center of the chips:

View attachment 737318

This is a 1" stamping blank

I place one of these babies on each side of the chip in my hydraulic heated press, like so:

View attachment 737319

Then press it for about a minute at a reasonable temp:

View attachment 737320

Then it comes out flattened and smooth in the middle:

View attachment 737322

Then you can stamp!

View attachment 737323

Similar threads

- Locked

- Replies

- 28

- Views

- 3K

- Replies

- 33

- Views

- 4K

- Replies

- 54

- Views

- 7K