Appreciate it as well! I have some chips currently in the mail that my reshipper @Ethan referred to as "straight up taco shells", so I definitely need to try out some flattening pretty soonThanks man! Now, I hope it's helpful to someone else and not just redundant

-

PCF is an Amazon Associate and an eBay Partner. If you make a purchase through one of our links, we may earn a commission at no extra cost to you. Thank you for your support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flattening Warped Chips (5 Viewers)

- Thread starter ski_ex5

- Start date

Colquhoun

4 of a Kind

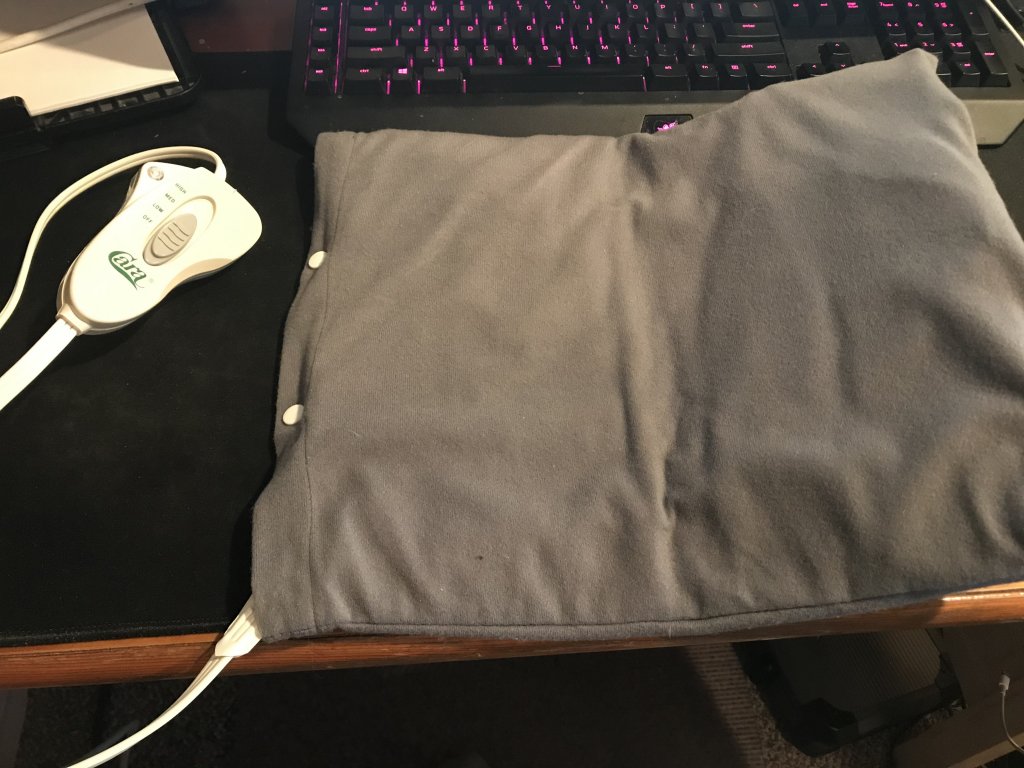

Here’s the way I’ve been flattening used HSI chips with great success. A generic heating pad on high ( pad says it is 142-168 degrees Fahrenheit.

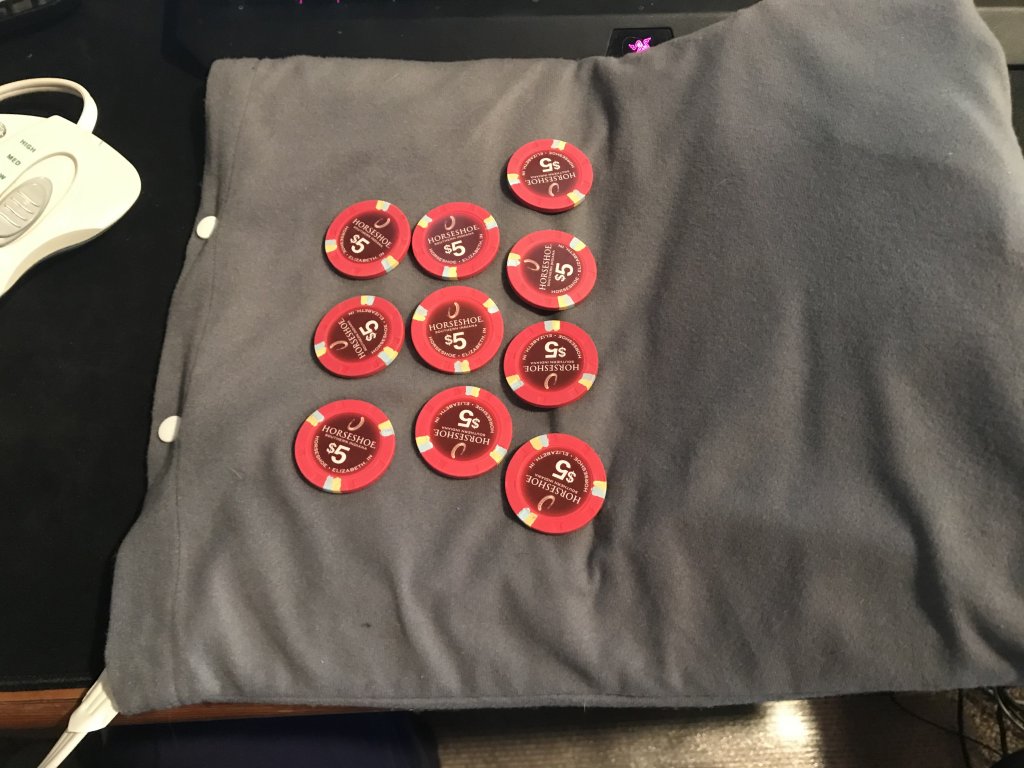

Lay 10 chips at a time in a single layer on 1/2 of the pad.

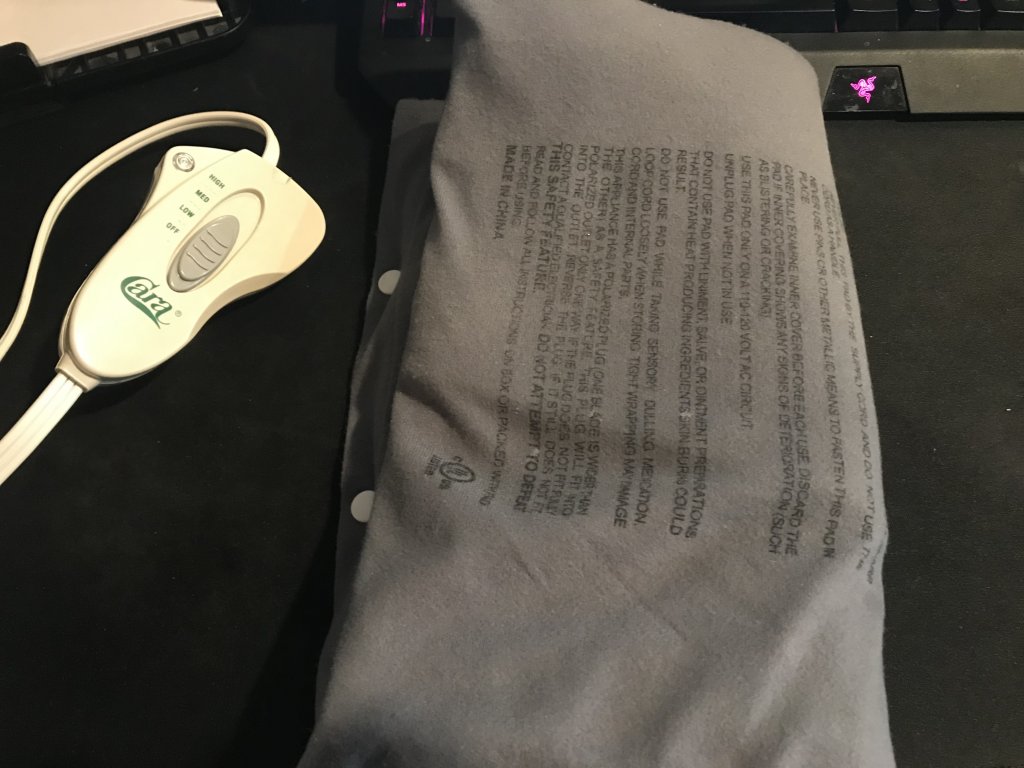

Fold over the pad, avoiding a sharp crease in the pad.

Heat for 10 minutes, sometimes holding the top of the pad down for good contact.

Heat for 10 minutes, sometimes holding the top of the pad down for good contact.

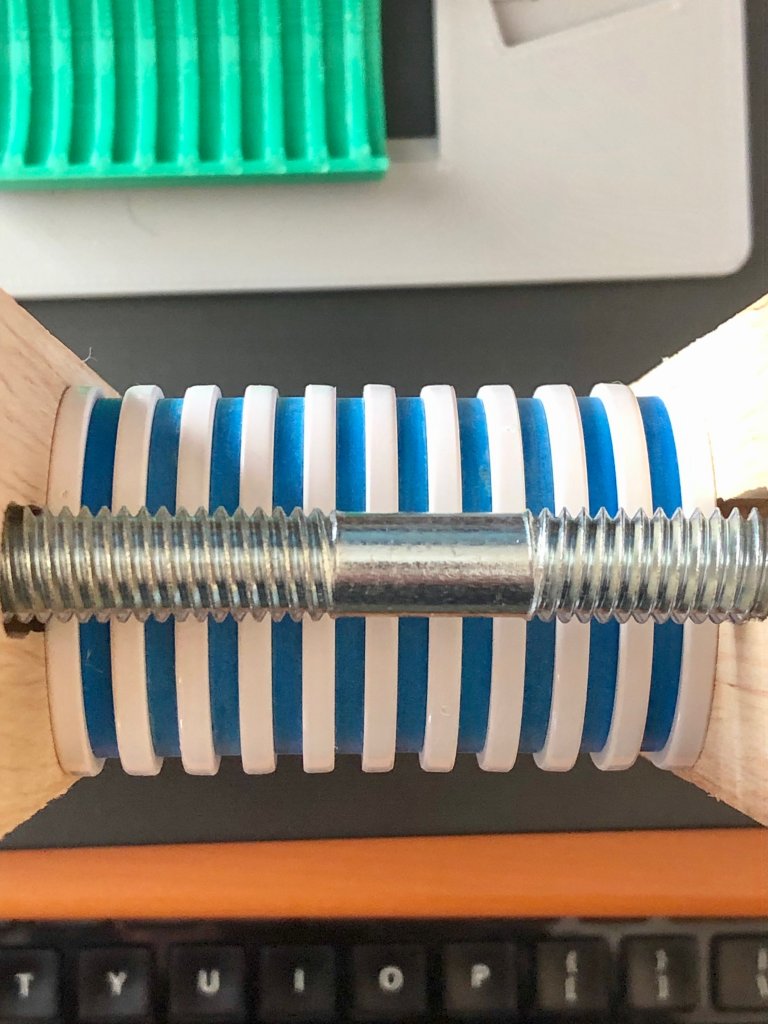

Remove the chips and then using ceramic blanks, carefully align them and clamp in a hand clamp (very snugly but not SUPER tight). I used colored DDLM ceramics with no color transfer on either the ceramic or the HSI chips. Blank ceramics would be preferable if available to remove all possibility.

Remove the chips and then using ceramic blanks, carefully align them and clamp in a hand clamp (very snugly but not SUPER tight). I used colored DDLM ceramics with no color transfer on either the ceramic or the HSI chips. Blank ceramics would be preferable if available to remove all possibility.

Let cool 1-2 hours. Flat chips!

Lay 10 chips at a time in a single layer on 1/2 of the pad.

Fold over the pad, avoiding a sharp crease in the pad.

Let cool 1-2 hours. Flat chips!

I'm going to do this while using the heating pad to keep me warm while I'm watching netflix.... Bam genius. Thanks for sharing this methodHere’s the way I’ve been flattening used HSI chips with great success. A generic heating pad on high ( pad says it is 142-168 degrees Fahrenheit.View attachment 604363

Lay 10 chips at a time in a single layer on 1/2 of the pad.

View attachment 604366

Fold over the pad, avoiding a sharp crease in the pad.

View attachment 604367Heat for 10 minutes, sometimes holding the top of the pad down for good contact.

View attachment 604375Remove the chips and then using ceramic blanks, carefully align them and clamp in a hand clamp (very snugly but not SUPER tight). I used colored DDLM ceramics with no color transfer on either the ceramic or the HSI chips. Blank ceramics would be preferable if available to remove all possibility.

Let cool 1-2 hours. Flat chips!

It worked quite well on some old, warped THC solids... it's not only for slightly off mint chips...I'm going to do this while using the heating pad to keep me warm while I'm watching netflix.... Bam genius. Thanks for sharing this method

OfficerLovejoy

Full House

I'm trying out the simplest method without involving temperature changes... I'll keep you posted on results.

Nevada jacks ceramics as spacers between the warped chips. Gonna leave it alone for 24 hours.

Nevada jacks ceramics as spacers between the warped chips. Gonna leave it alone for 24 hours.

What's next, a picture of one of us sitting on a stack like a mother hen?

OfficerLovejoy

Full House

Hold on a minute! That would solve my lack of temperature change!What's next, a picture of one of us sitting on a stack like a mother hen?

Colquhoun

4 of a Kind

The way I figure it, heat is what likely warped them, it will take a little heat to un-warp them. Heat will also make it less likely that they return to that warped state.

OfficerLovejoy

Full House

Yes, that is most probably true. Some users are reporting success just by putting some pressure on the chips at room temperature, so I'm trying that out first before ordering a heating pad.

GenghisKhan

Full House

- Joined

- Nov 7, 2014

- Messages

- 2,898

- Reaction score

- 4,722

Yes, that is most probably true. Some users are reporting success just by putting some pressure on the chips at room temperature, so I'm trying that out first before ordering a heating pad.

Do we have people saying this was a permanent solution? Afaik, chips return to their exact warped shape after a short while.

(I've tried this before myself and it did not last. I think it returned within days.)

Absolutely no harm in trying, just curious if someone found a way to make this a permanent solution.

I can say for sure, without a shadow of a doubt, blink of an eye, that putting them in a clamp in the oven while you’re baking a pizza for the kids at 400F will flatten them. Full disclosure, I never said for how long but I’ll be damned if those things aren’t flat as f*#k by the time they’re out.

Last edited:

OfficerLovejoy

Full House

I disassembled my shaky construction to check on the chips.I'm trying out the simplest method without involving temperature changes... I'll keep you posted on results.

View attachment 604521

Nevada jacks ceramics as spacers between the warped chips. Gonna leave it alone for 24 hours.

I'd say there is an improvement, but the chips are not completely flat yet.

As @Colquhoun pointed out, heat is probably needed. I'm gonna get a clamp first and proceed from there.

During the summer, I started to feel out the process of flattening some chips that i have, and like most people, I've tried out different methods posted here. I finally settled on what seems to work best for me to get consistent and lasting results. Some of the info is repeating the OP and others who've posted here:

DISCLAIMER: I've only used this method on Paulson THC hot stamp chips only so far. Everyone's oven will be different - some will heat up quicker and hold the heat longer.

Example results:

NOTES and observations/opinions

DISCLAIMER: I've only used this method on Paulson THC hot stamp chips only so far. Everyone's oven will be different - some will heat up quicker and hold the heat longer.

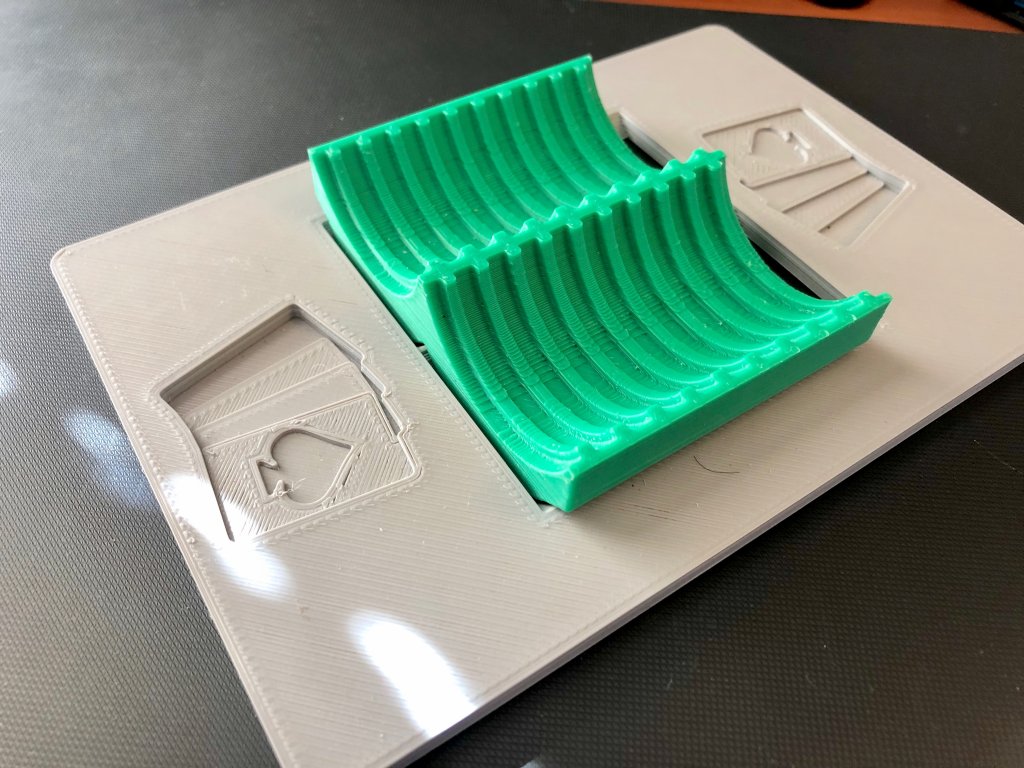

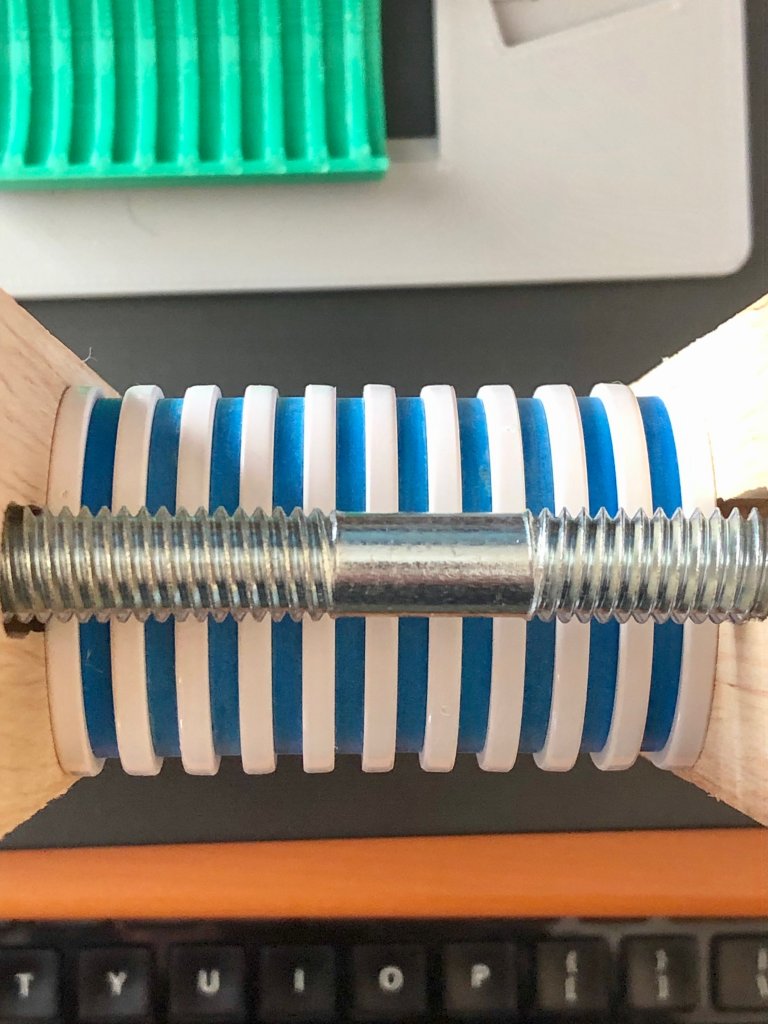

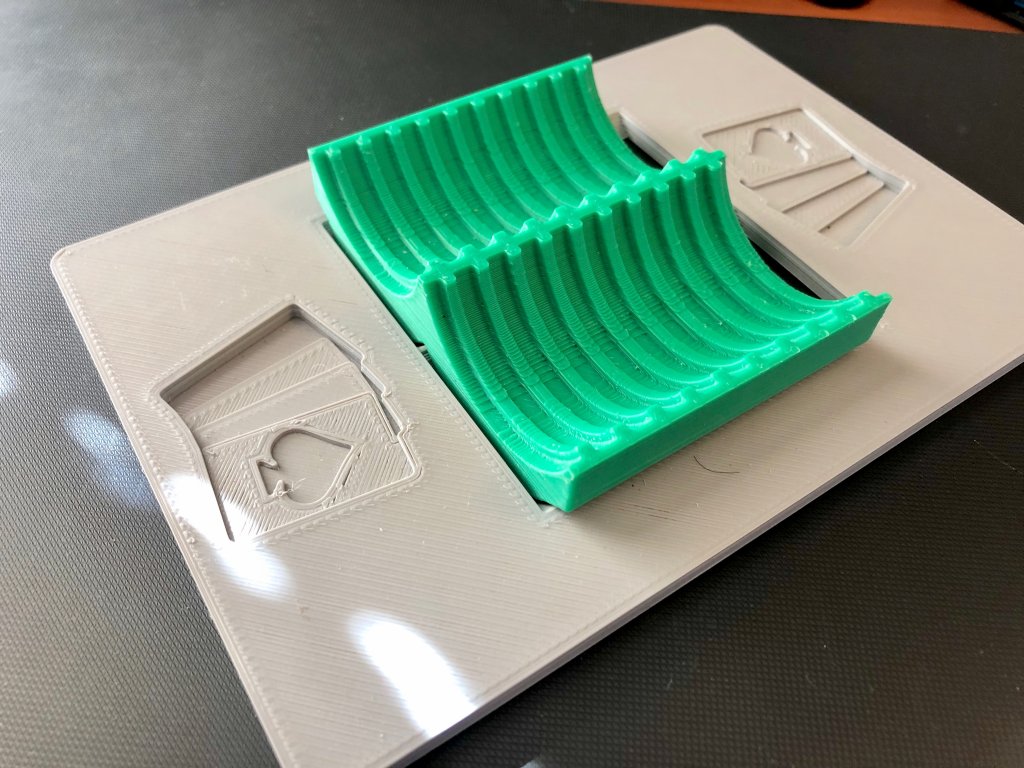

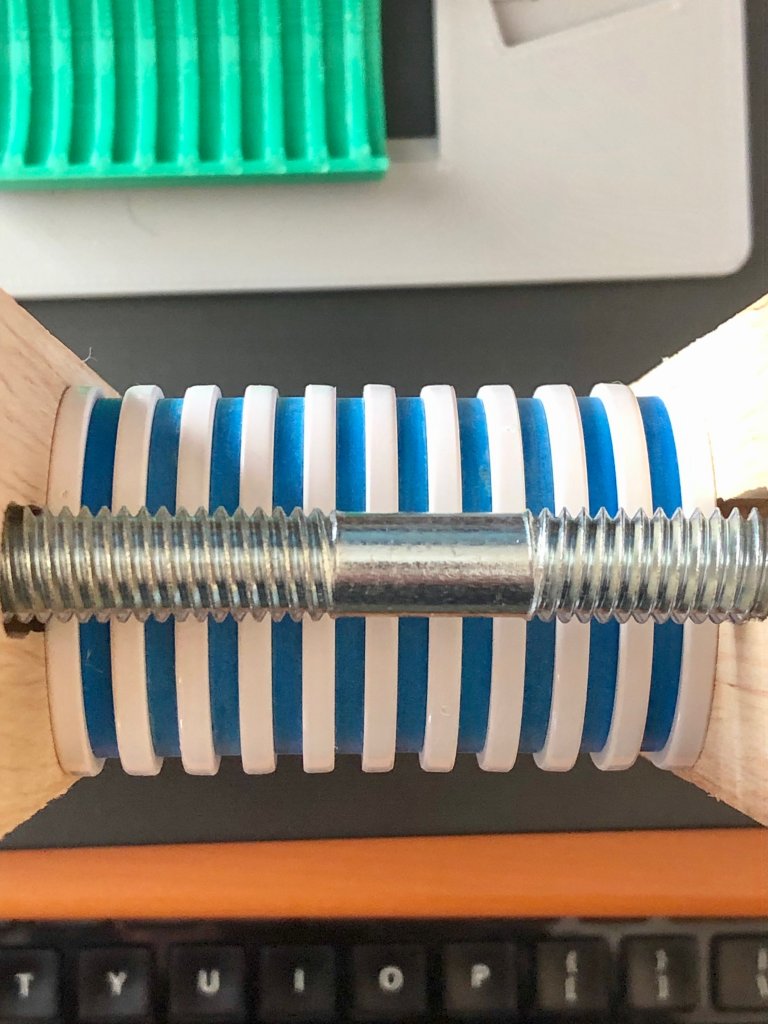

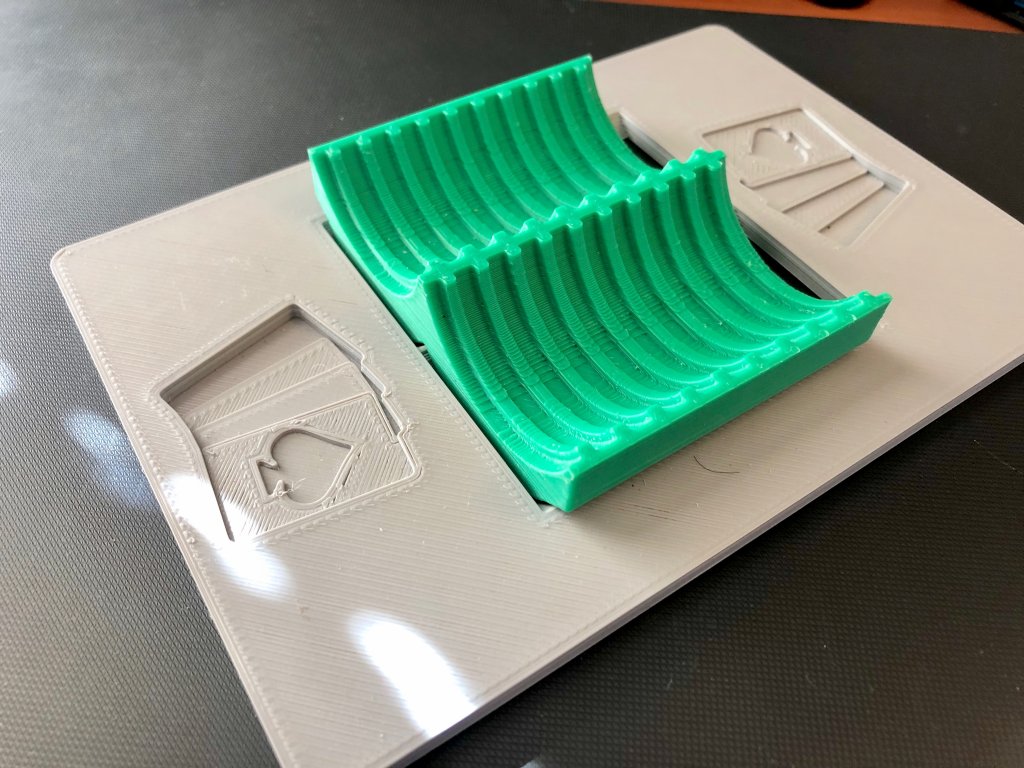

- Chip & Clamp setup used for 20x chips (one barrel total):

- 21 chip - 43mm ribbed Chip Flattening Rack @One Eyed Dollar

- 12" POWERTEC Handscrew Clamp (These work just as fine as the Bessey and are one of the more affordable options at the moment; 2x @ $42. I also have a 12" Bessey but prices on those have spiked recently).

- 22x 43mm Blank Ceramic spacers (available from @BR Pro Poker)

- I prefer the 12" clamp and the 43mm blanks setup for a couple of reasons:

- It allows for clearance all around the chip/spacers (see pic #3 & #4), and the clamps lay flat on the oven racks without having the chips or spacers touch the metal, which makes me more comfortable.

- You're able to get more torque and even pressure when tightening (don't need to kill it though) and the 12" clamps tend to stay in place better than the 10" or less versions (all sizes of clamps will need tightening directly after baking and periodically while cooling imo, you'll need to tighten the clamp less often when using a 12").

- Note: This set up and the placement of the chips/spacers will not work with a 10" clamp using the 43mm spacers, you'll only be able to fit one row (10x chips) in between the tightening screws.

- Temperature and time (I've been using a standard, non-convection Hotpoint brand oven - means there's no fan inside the oven):

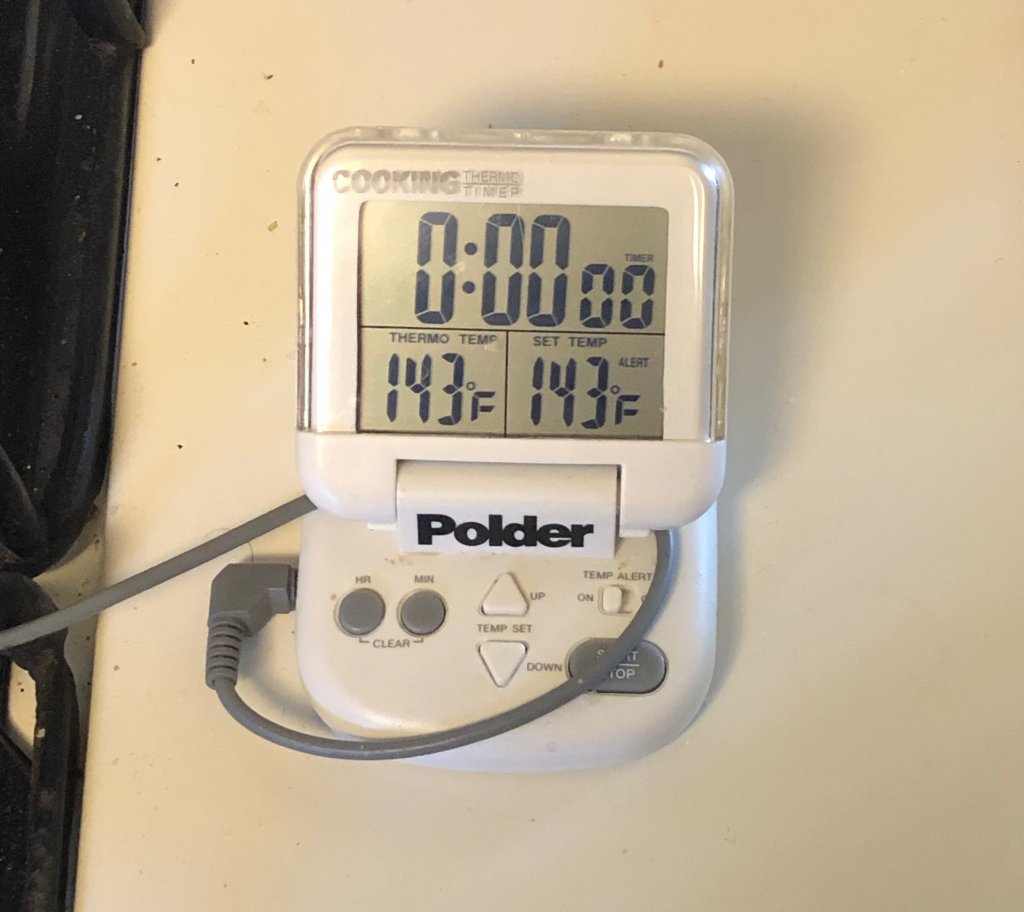

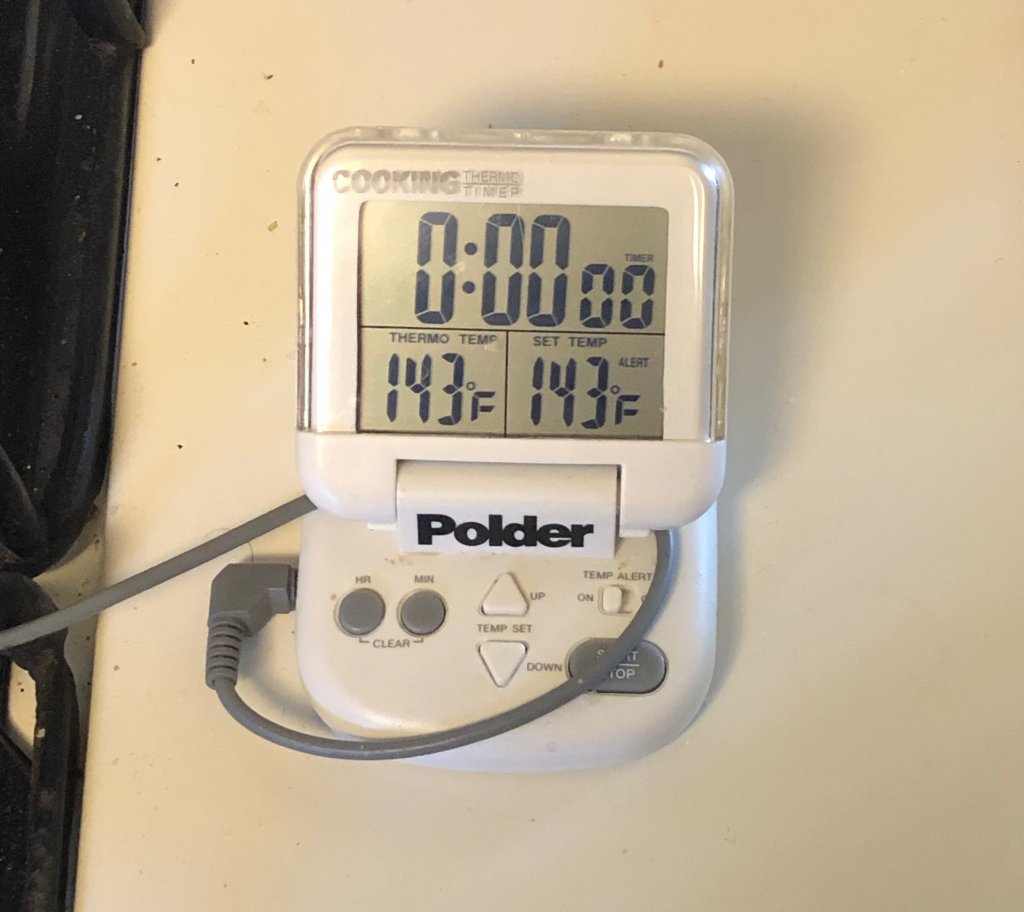

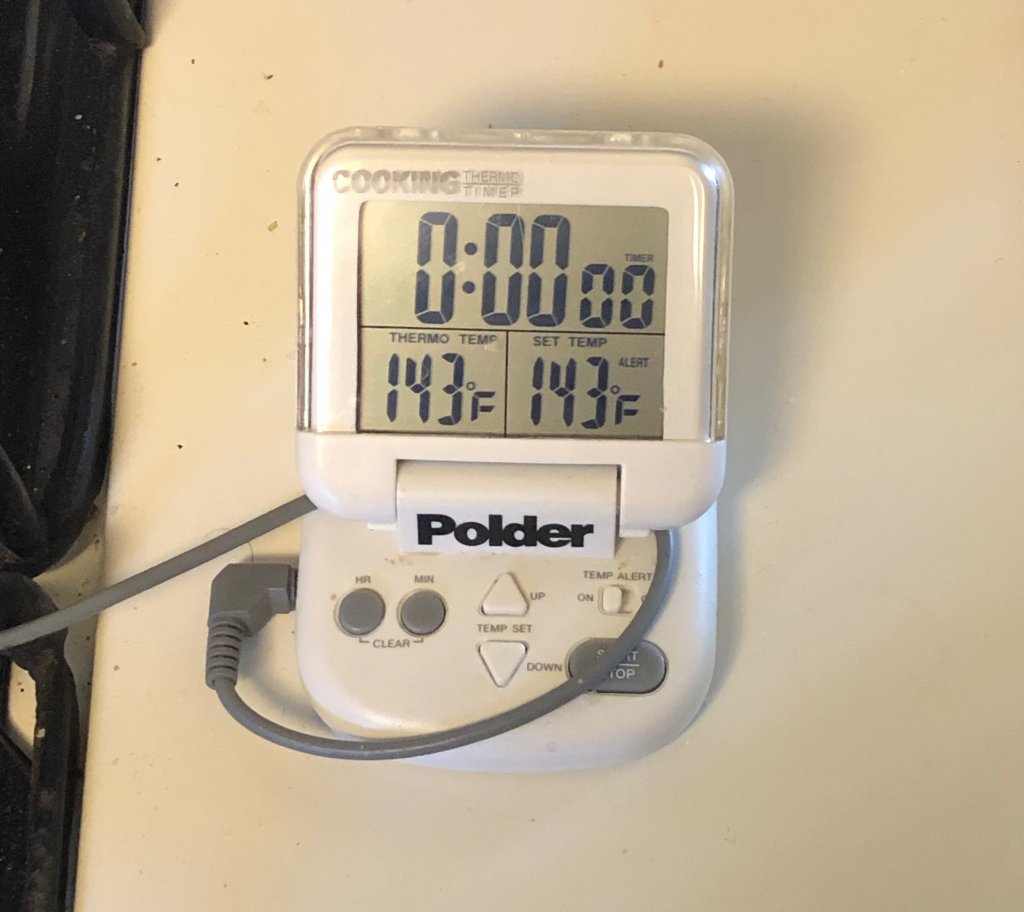

- I don't use my oven's temperature settings. I use a Polder thermometer probe and suspend the probe inside my oven (similar to @BSteck's setup), making sure the probe doesn't touch anything to get a more accurate temperature inside my oven.

- Target range is 130F to ~160F with a goal of keeping it ~140F for at least 45-60 minutes (w/o opening the oven door constantly).

- I use a temperature range, because it's nearly impossible for me to maintain an exact temperature for an extended period of time with my oven (as with most of our ovens). Instead, I do the following:

- I pre-heat my oven until the probe temp hits 143F then shut it off; the temperature will continue to rise to ~155-160F after I shut off my oven and then steadily decrease thereafter.

- Depending on the ambient temperature in my kitchen, it takes about 15 minutes for the internal oven temp to reach 130F on the probe - at this time, I'll turn on my oven again until the temp hits 143F again, shut it off and repeat this step 2 more times.

- Don't freak out if you accidently allow the temperature to go above this range. You can always open the door to release some heat and bring down the temperature quicker.

- I know some may think my temperature settings/recommendations are too high, but please see below for my reasoning.

- As mentioned above, I keep the internal temperature of my oven between 130F and 160F. I've done this for +1,000 chips so far with no damage to any of my chips. I've hit an oven temp as high as 170F for some batches with no ill effects; however, I don't recommend going over 160F. I think it's not necessary to heat the chips at that high of a temperature.

- I'm comfortable between 130F to 160F with a goal of keeping it around 140F, because even though the oven temp might seem high, the estimated outside temperature of the chips is still within the ~120F-130F range. The internal temp of the chips/spacers might be a bit higher than this range, but again, I have not had a problem so far. I've used this process on very used chips to Near Mint chips. The snapshots below were taken as soon as i opened the oven door at two different points during my heating process:

- Cooling:

- Right after taking the clamps from the oven, I tighten them down. No need to kill it or tighten the clams as much as possible - I just tighten them until i feel there's pressure on the chips again. Everything expands a bit in the oven, and the clamps tend to loosen slightly.

- As the chips continue to cool, I continue to tighten the clamps slightly - especially every 3-5 minutes for the first ~20 minutes after removing them from the heat. After this ~20 minute period, i tighten the clamp periodically just in case, but most of the time it's not necessary, especially after an hour of cooling.

- I let the chips completely cool to room temperature before removing from the clamps - usually takes ~3-5 hours, depending on the ambient temperature in my kitchen.

- I have tried speeding up this process by using a small fan and more tightening of the clamps in a shorter period of time, but I felt I got better results by letting them cool down naturally.

- I haven't seen too much of a difference between cooling to room temp and leaving them in the clamp for hours more; however, it doesn't hurt to keep them in the clamp for as long as you'd like. My heating process is longer than most, so the cooling time is already extended, but with that said, i have kept chips to cool for 24+ hours with the same or similar results as cooling to room temp.

Example results:

- Before heating/clamping next to a Mint barrel

- After the process next to the same Mint barrel, and then next to another pre-flattened barrel

NOTES and observations/opinions

- For my oven, heating at 120F for 20-30 minutes did not yield lasting results IMO. After cooling at room temp, some chips had flattened but there were a few that refused to flatten. Even running the same barrel again with the same process, I yielded the same results.

- For me, the process that i described above has yielded nearly all flat chips after the first pass; however, there are still the outlier chips that will need a second run.

- Keeping constant pressure and tightening the clamps while cooling is important.

- The first batch of 400 chips that i tested this process on, were all very used and very warped chips. Of the first 400 chips, nearly all needed a second run. A month after the second run, I notice that some chips reverted back to being slightly warped again - these were probably the ones that had the most extreme bends; however, 3 months later, the vast majority of this batch remains flat and stack really well.

- After utilizing this process on many chips afterwards, I noticed that regardless if the chip is very casino used or Near Mint - if the chip has extreme warping, it's possible to get them completely flat, but most likely there's a chance that they will eventually show some slight warpage as time goes on. From my experience, when these chips do revert back a bit, they haven't returned to the extreme warped state that they were previously in.

- This has happened in as short of a period of 24-48 hours after removing them from the clamp. Some have taken a week or longer to show signs of warping.

- The clamping times for these batch were the same as mentioned above - a minimum of 3-5 hours (cooled to room temp) and as long as 24+ hours. FWIW, the few chips that showed signs of warping again after 24-48 were NM and clamped for 24+ hours.

- Highly recommend cleaning beforehand, especially if you use an ultrasonic cleaner. I haven't seen consistent proof of this, but the one batch I did flatten first, then cleaned with an u/s cleaner, i noticed that the warping had returned to quite a few chips after a pre-soak and bath in the u/s.

Sorry all, I accidentally posted that i used a 22-chip ribbed 43mm chip flattening rack from @One Eyed Dollar; however, it was supposed to be the 21-chip ribbed 43mm chip flattening rack. @DZPoker caught the error but only after he had picked up the 22-chip rack, which was listed in my original post  . I couldn't edited the post, so I reposted with the correction.

. I couldn't edited the post, so I reposted with the correction.

. I couldn't edited the post, so I reposted with the correction.

. I couldn't edited the post, so I reposted with the correction.This is an awesome post. So u keep ur chips in the oven for 45 mins at around 130 degrees? I thought is was only 15 mins bake time.During the summer, I started to feel out the process of flattening some chips that i have, and like most people, I've tried out different methods posted here. I finally settled on what seems to work best for me to get consistent and lasting results. Some of the info is repeating the OP and others who've posted here:

DISCLAIMER: I've only used this method on Paulson THC hot stamp chips only so far. Everyone's oven will be different - some will heat up quicker and hold the heat longer.

- Chip & Clamp setup used for 20x chips (one barrel total):

- 21 chip - 43mm ribbed Chip Flattening Rack @One Eyed Dollar

- 12" POWERTEC Handscrew Clamp (These work just as fine as the Bessey and are one of the more affordable options at the moment; 2x @ $42. I also have a 12" Bessey but prices on those have spiked recently).

- 22x 43mm Blank Ceramic spacers (available from @BR Pro Poker)

- I prefer the 12" clamp and the 43mm blanks setup for a couple of reasons:

- It allows for clearance all around the chip/spacers (see pic #3 & #4), and the clamps lay flat on the oven racks without having the chips or spacers touch the metal, which makes me more comfortable.

- You're able to get more torque and even pressure when tightening (don't need to kill it though) and the 12" clamps tend to stay in place better than the 10" or less versions (all sizes of clamps will need tightening directly after baking and periodically while cooling imo, you'll need to tighten the clamp less often when using a 12").

- Note: This set up and the placement of the chips/spacers will not work with a 10" clamp using the 43mm spacers, you'll only be able to fit one row (10x chips) in between the tightening screws.

- Temperature and time (I've been using a standard, non-convection Hotpoint brand oven - means there's no fan inside the oven):

- I don't use my oven's temperature settings. I use a Polder thermometer probe and suspend the probe inside my oven (similar to @BSteck's setup), making sure the probe doesn't touch anything to get a more accurate temperature inside my oven.

- Target range is 130F to ~160F with a goal of keeping it ~140F for at least 45-60 minutes (w/o opening the oven door constantly).

- I use a temperature range, because it's nearly impossible for me to maintain an exact temperature for an extended period of time with my oven (as with most of our ovens). Instead, I do the following:

- I pre-heat my oven until the probe temp hits 143F then shut it off; the temperature will continue to rise to ~155-160F after I shut off my oven and then steadily decrease thereafter.

- Depending on the ambient temperature in my kitchen, it takes about 15 minutes for the internal oven temp to reach 130F on the probe - at this time, I'll turn on my oven again until the temp hits 143F again, shut it off and repeat this step 2 more times.

- Don't freak out if you accidently allow the temperature to go above this range. You can always open the door to release some heat and bring down the temperature quicker.

- I know some may think my temperature settings/recommendations are too high, but please see below for my reasoning.

- As mentioned above, I keep the internal temperature of my oven between 130F and 160F. I've done this for +1,000 chips so far with no damage to any of my chips. I've hit an oven temp as high as 170F for some batches with no ill effects; however, I don't recommend going over 160F. I think it's not necessary to heat the chips at that high of a temperature.

- I'm comfortable between 130F to 160F with a goal of keeping it around 140F, because even though the oven temp might seem high, the estimated outside temperature of the chips is still within the ~120F-130F range. The internal temp of the chips/spacers might be a bit higher than this range, but again, I have not had a problem so far. I've used this process on very used chips to Near Mint chips. The snapshots below were taken as soon as i opened the oven door at two different points during my heating process:

(pic taken directly out of the oven)

- Cooling:

- Right after taking the clamps from the oven, I tighten them down. No need to kill it or tighten the clams as much as possible - I just tighten them until i feel there's pressure on the chips again. Everything expands a bit in the oven, and the clamps tend to loosen slightly.

- As the chips continue to cool, I continue to tighten the clamps slightly - especially every 3-5 minutes for the first ~20 minutes after removing them from the heat. After this ~20 minute period, i tighten the clamp periodically just in case, but most of the time it's not necessary, especially after an hour of cooling.

- I let the chips completely cool to room temperature before removing from the clamps - usually takes ~3-5 hours, depending on the ambient temperature in my kitchen.

- I have tried speeding up this process by using a small fan and more tightening of the clamps in a shorter period of time, but I felt I got better results by letting them cool down naturally.

- I haven't seen too much of a difference between cooling to room temp and leaving them in the clamp for hours more; however, it doesn't hurt to keep them in the clamp for as long as you'd like. My heating process is longer than most, so the cooling time is already extended, but with that said, i have kept chips to cool for 24+ hours with the same or similar results as cooling to room temp.

Example results:

- Before heating/clamping next to a Mint barrel

- After the process next to the same Mint barrel, and then next to another pre-flattened barrel

NOTES and observations/opinions

- For my oven, heating at 120F for 20-30 minutes did not yield lasting results IMO. After cooling at room temp, some chips had flattened but there were a few that refused to flatten. Even running the same barrel again with the same process, I yielded the same results.

- For me, the process that i described above has yielded nearly all flat chips after the first pass; however, there are still the outlier chips that will need a second run.

- Keeping constant pressure and tightening the clamps while cooling is important.

- The first batch of 400 chips that i tested this process on, were all very used and very warped chips. Of the first 400 chips, nearly all needed a second run. A month after the second run, I notice that some chips reverted back to being slightly warped again - these were probably the ones that had the most extreme bends; however, 3 months later, the vast majority of this batch remains flat and stack really well.

- After utilizing this process on many chips afterwards, I noticed that regardless if the chip is very casino used or Near Mint - if the chip has extreme warping, it's possible to get them completely flat, but most likely there's a chance that they will eventually show some slight warpage as time goes on. From my experience, when these chips do revert back a bit, they haven't returned to the extreme warped state that they were previously in.

- This has happened in as short of a period of 24-48 hours after removing them from the clamp. Some have taken a week or longer to show signs of warping.

- The clamping times for these batch were the same as mentioned above - a minimum of 3-5 hours (cooled to room temp) and as long as 24+ hours. FWIW, the few chips that showed signs of warping again after 24-48 were NM and clamped for 24+ hours.

- Highly recommend cleaning beforehand, especially if you use an ultrasonic cleaner. I haven't seen consistent proof of this, but the one batch I did flatten first, then cleaned with an u/s cleaner, i noticed that the warping had returned to quite a few chips after a pre-soak and bath in the u/s.

Personally, i try to keep it around 140degrees for 45 minutes. Everyone's oven is different though, so keep that in mind. I experimented with different temps and times on multiple batches of different chips, but this time and temp target gave me the best results without damaging the chips.This is an awesome post. So u keep ur chips in the oven for 45 mins at around 130 degrees? I thought is was only 15 mins bake time.

Colquhoun

4 of a Kind

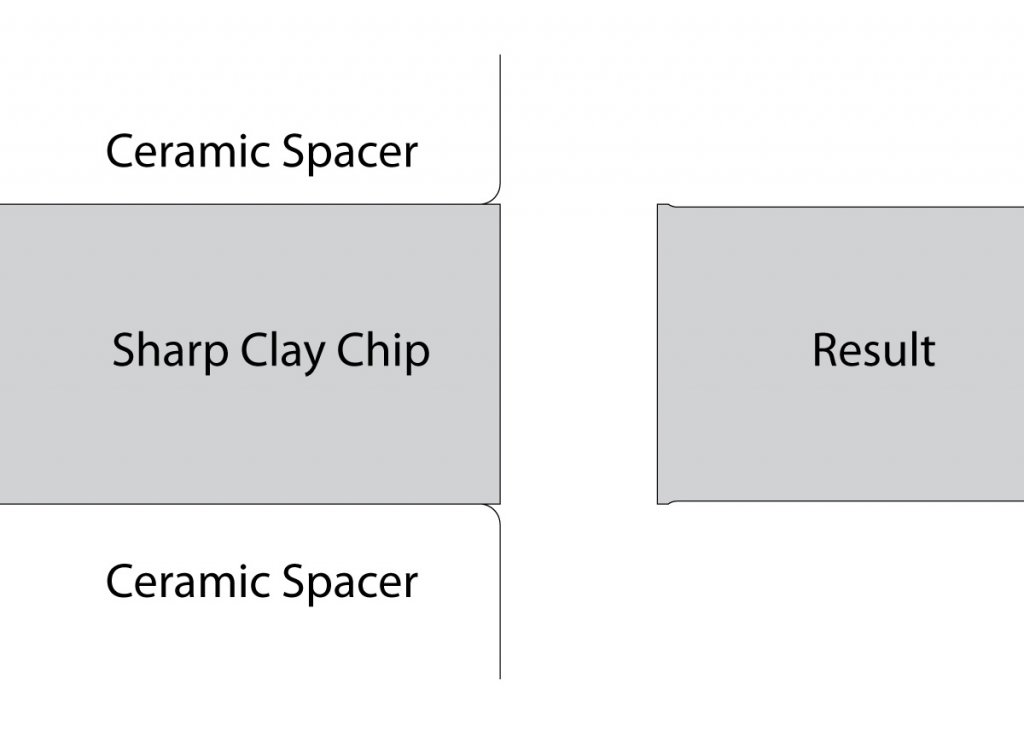

Just and update...I started flattening some brand new Paulsons and noticed that the 39mm ceramic spacers are just a WEE bit smaller than the clay Palsons. The ceramic is indeed the same size on the outside edge...however, since the ceramic chip has a SLIGHT round-over going from its face to the rolling edge, when pressed against a new SHARP Paulson, it leaves a very small ridge on the outer edge of the face of the chips.

As has been recommended by others, using 43mm spacers is the way to go, ESPECIALLY on new chips.

Here's an illustration:

As has been recommended by others, using 43mm spacers is the way to go, ESPECIALLY on new chips.

Here's an illustration:

- Joined

- Jul 12, 2020

- Messages

- 10,391

- Reaction score

- 16,323

looks like a reinforced edge now. I don't see the downside.Just and update...I started flattening some brand new Paulsons and noticed that the 39mm ceramic spacers are just a WEE bit smaller than the clay Palsons. The ceramic is indeed the same size on the outside edge...however, since the ceramic chip has a SLIGHT round-over going from its face to the rolling edge, when pressed against a new SHARP Paulson, it leaves a very small ridge on the outer edge of the face of the chips.

As has been recommended by others, using 43mm spacers is the way to go, ESPECIALLY on new chips.

Here's an illustration:

View attachment 624572

Colquhoun

4 of a Kind

looks like a reinforced edge now. I don't see the downside.

If you're using enough pressure for the chip to flatten to the form of thr ceramic chips won't it just squish the whole chip? I guess if you measure after and it hasnt gotten wider then it isnt. What about the cross hatching?Just and update...I started flattening some brand new Paulsons and noticed that the 39mm ceramic spacers are just a WEE bit smaller than the clay Palsons. The ceramic is indeed the same size on the outside edge...however, since the ceramic chip has a SLIGHT round-over going from its face to the rolling edge, when pressed against a new SHARP Paulson, it leaves a very small ridge on the outer edge of the face of the chips.

As has been recommended by others, using 43mm spacers is the way to go, ESPECIALLY on new chips.

Here's an illustration:

View attachment 624572

- Joined

- Jul 12, 2020

- Messages

- 10,391

- Reaction score

- 16,323

got a real life working pic of your reinforced edge chip?Just and update...I started flattening some brand new Paulsons and noticed that the 39mm ceramic spacers are just a WEE bit smaller than the clay Palsons. The ceramic is indeed the same size on the outside edge...however, since the ceramic chip has a SLIGHT round-over going from its face to the rolling edge, when pressed against a new SHARP Paulson, it leaves a very small ridge on the outer edge of the face of the chips.

As has been recommended by others, using 43mm spacers is the way to go, ESPECIALLY on new chips.

Here's an illustration:

View attachment 624572

boltonguy

Flush

Have a source for the 43 mm spacers pls?

- Joined

- Jul 12, 2020

- Messages

- 10,391

- Reaction score

- 16,323

@BR Pro PokerHave a source for the 43 mm spacers pls?

Colquhoun

4 of a Kind

I did a few chips, these were the best example. Some chips showed no ridge at all. 43mm or nothing!got a real life working pic of your reinforced edge chip?

- Joined

- Jul 12, 2020

- Messages

- 10,391

- Reaction score

- 16,323

they look like thc/rhc hybrids nowI did a few chips, these were the best example. Some chips showed no ridge at all. 43mm or nothing!

View attachment 624616

View attachment 624617

Colquhoun

4 of a Kind

Granted we are talking about a very small sliver of a ridge...these are fairly closeup photos.

Especially in that 2nd one, we're talking 1/4 the distance between the hat and the edge on a RHC chip? That's pretty small!

Especially in that 2nd one, we're talking 1/4 the distance between the hat and the edge on a RHC chip? That's pretty small!

TeamNapoli

Straight

During the summer, I started to feel out the process of flattening some chips that i have, and like most people, I've tried out different methods posted here. I finally settled on what seems to work best for me to get consistent and lasting results. Some of the info is repeating the OP and others who've posted here:

DISCLAIMER: I've only used this method on Paulson THC hot stamp chips only so far. Everyone's oven will be different - some will heat up quicker and hold the heat longer.

- Chip & Clamp setup used for 20x chips (one barrel total):

- 21 chip - 43mm ribbed Chip Flattening Rack @One Eyed Dollar

- 12" POWERTEC Handscrew Clamp (These work just as fine as the Bessey and are one of the more affordable options at the moment; 2x @ $42. I also have a 12" Bessey but prices on those have spiked recently).

- 22x 43mm Blank Ceramic spacers (available from @BR Pro Poker)

- I prefer the 12" clamp and the 43mm blanks setup for a couple of reasons:

- It allows for clearance all around the chip/spacers (see pic #3 & #4), and the clamps lay flat on the oven racks without having the chips or spacers touch the metal, which makes me more comfortable.

- You're able to get more torque and even pressure when tightening (don't need to kill it though) and the 12" clamps tend to stay in place better than the 10" or less versions (all sizes of clamps will need tightening directly after baking and periodically while cooling imo, you'll need to tighten the clamp less often when using a 12").

- Note: This set up and the placement of the chips/spacers will not work with a 10" clamp using the 43mm spacers, you'll only be able to fit one row (10x chips) in between the tightening screws.

- Temperature and time (I've been using a standard, non-convection Hotpoint brand oven - means there's no fan inside the oven):

- I don't use my oven's temperature settings. I use a Polder thermometer probe and suspend the probe inside my oven (similar to @BSteck's setup), making sure the probe doesn't touch anything to get a more accurate temperature inside my oven.

- Target range is 130F to ~160F with a goal of keeping it ~140F for at least 45-60 minutes (w/o opening the oven door constantly).

- I use a temperature range, because it's nearly impossible for me to maintain an exact temperature for an extended period of time with my oven (as with most of our ovens). Instead, I do the following:

- I pre-heat my oven until the probe temp hits 143F then shut it off; the temperature will continue to rise to ~155-160F after I shut off my oven and then steadily decrease thereafter.

- Depending on the ambient temperature in my kitchen, it takes about 15 minutes for the internal oven temp to reach 130F on the probe - at this time, I'll turn on my oven again until the temp hits 143F again, shut it off and repeat this step 2 more times.

- Don't freak out if you accidently allow the temperature to go above this range. You can always open the door to release some heat and bring down the temperature quicker.

- I know some may think my temperature settings/recommendations are too high, but please see below for my reasoning.

- As mentioned above, I keep the internal temperature of my oven between 130F and 160F. I've done this for +1,000 chips so far with no damage to any of my chips. I've hit an oven temp as high as 170F for some batches with no ill effects; however, I don't recommend going over 160F. I think it's not necessary to heat the chips at that high of a temperature.

- I'm comfortable between 130F to 160F with a goal of keeping it around 140F, because even though the oven temp might seem high, the estimated outside temperature of the chips is still within the ~120F-130F range. The internal temp of the chips/spacers might be a bit higher than this range, but again, I have not had a problem so far. I've used this process on very used chips to Near Mint chips. The snapshots below were taken as soon as i opened the oven door at two different points during my heating process:

(pic taken directly out of the oven)

- Cooling:

- Right after taking the clamps from the oven, I tighten them down. No need to kill it or tighten the clams as much as possible - I just tighten them until i feel there's pressure on the chips again. Everything expands a bit in the oven, and the clamps tend to loosen slightly.

- As the chips continue to cool, I continue to tighten the clamps slightly - especially every 3-5 minutes for the first ~20 minutes after removing them from the heat. After this ~20 minute period, i tighten the clamp periodically just in case, but most of the time it's not necessary, especially after an hour of cooling.

- I let the chips completely cool to room temperature before removing from the clamps - usually takes ~3-5 hours, depending on the ambient temperature in my kitchen.

- I have tried speeding up this process by using a small fan and more tightening of the clamps in a shorter period of time, but I felt I got better results by letting them cool down naturally.

- I haven't seen too much of a difference between cooling to room temp and leaving them in the clamp for hours more; however, it doesn't hurt to keep them in the clamp for as long as you'd like. My heating process is longer than most, so the cooling time is already extended, but with that said, i have kept chips to cool for 24+ hours with the same or similar results as cooling to room temp.

Example results:

- Before heating/clamping next to a Mint barrel

- After the process next to the same Mint barrel, and then next to another pre-flattened barrel

NOTES and observations/opinions

- For my oven, heating at 120F for 20-30 minutes did not yield lasting results IMO. After cooling at room temp, some chips had flattened but there were a few that refused to flatten. Even running the same barrel again with the same process, I yielded the same results.

- For me, the process that i described above has yielded nearly all flat chips after the first pass; however, there are still the outlier chips that will need a second run.

- Keeping constant pressure and tightening the clamps while cooling is important.

- The first batch of 400 chips that i tested this process on, were all very used and very warped chips. Of the first 400 chips, nearly all needed a second run. A month after the second run, I notice that some chips reverted back to being slightly warped again - these were probably the ones that had the most extreme bends; however, 3 months later, the vast majority of this batch remains flat and stack really well.

- After utilizing this process on many chips afterwards, I noticed that regardless if the chip is very casino used or Near Mint - if the chip has extreme warping, it's possible to get them completely flat, but most likely there's a chance that they will eventually show some slight warpage as time goes on. From my experience, when these chips do revert back a bit, they haven't returned to the extreme warped state that they were previously in.

- This has happened in as short of a period of 24-48 hours after removing them from the clamp. Some have taken a week or longer to show signs of warping.

- The clamping times for these batch were the same as mentioned above - a minimum of 3-5 hours (cooled to room temp) and as long as 24+ hours. FWIW, the few chips that showed signs of warping again after 24-48 were NM and clamped for 24+ hours.

- Highly recommend cleaning beforehand, especially if you use an ultrasonic cleaner. I haven't seen consistent proof of this, but the one batch I did flatten first, then cleaned with an u/s cleaner, i noticed that the warping had returned to quite a few chips after a pre-soak and bath in the u/s.

I have used the same process and it has worked time after time for me.

I will add that when i pre heat the oven i also put the clamps in allowing the metal and wood to expand to their dimensions at that temperature.

I will also say that the Chip Flattening Rack made by 3D3P (@One Eyed Dollar ) is a must. It makes life so much easier centering the chips and ceramics. DAM it!! I purchased the first model when they were non ribbed, now I have to get the ribbed ones. I hear the ribbed ones make it a more pleasurable process

One Eyed Dollar

Flush

I have used the same process and it has worked time after time for me.

I will add that when i pre heat the oven i also put the clamps in allowing the metal and wood to expand to their dimensions at that temperature.

I will also say that the Chip Flattening Rack made by 3D3P (@One Eyed Dollar ) is a must. It makes life so much easier centering the chips and ceramics. DAM it!! I purchased the first model when they were non ribbed, now I have to get the ribbed ones. I hear the ribbed ones make it a more pleasurable process

Maybe you're using to much pressure? I just checked some THC and RHC chips I've flattened and there's no evidence of this on mineI did a few chips, these were the best example. Some chips showed no ridge at all. 43mm or nothing!

View attachment 624616

View attachment 624617

OfficerLovejoy

Full House

I've had my first chip flattening experience and had to learn some stuff the hard way.

I had some bad color transfer issues on some of the chips. I used some old nevada jacks ceramics I had lying around.

The chips were freshly cleaned before getting clamped and the color / dirt was a pain to remove afterwards.

Here is my process and my theory how this went wrong:

I felt it was easiest without a heating pad, to just throw the chips with the ceramics as spacers into a plastic cup and heat them up in a water based bottle warmer for baby bottles.

This created a beautifully controlled temperature but in turn steamed the chips with water vapor, to make them hot and wet.

I could already tell I'd fudged this up when I had to force the chips to split from the ceramics after having them clamped for like 8 hours.

I don't see any discoloration or damage on the ceramics, but something definately got transferred onto (and into) the clay chips. It could also have been dirt or hooker juice, since these ceramics had been felted many times over the last years and I did not clean them beforehand, since I did not see any dirt on them when I got them out of their case.

It took me about 10 min/chip to remove the color / baked in dirt from the clay chips with a magic eraser, dish soap and a hard sponge.

So in conclusion:

Don't use water / steam to heat up the chips.

Use clean ceramic blanks to make sure, no color gets transferred.

I had some bad color transfer issues on some of the chips. I used some old nevada jacks ceramics I had lying around.

The chips were freshly cleaned before getting clamped and the color / dirt was a pain to remove afterwards.

Here is my process and my theory how this went wrong:

I felt it was easiest without a heating pad, to just throw the chips with the ceramics as spacers into a plastic cup and heat them up in a water based bottle warmer for baby bottles.

This created a beautifully controlled temperature but in turn steamed the chips with water vapor, to make them hot and wet.

I could already tell I'd fudged this up when I had to force the chips to split from the ceramics after having them clamped for like 8 hours.

I don't see any discoloration or damage on the ceramics, but something definately got transferred onto (and into) the clay chips. It could also have been dirt or hooker juice, since these ceramics had been felted many times over the last years and I did not clean them beforehand, since I did not see any dirt on them when I got them out of their case.

It took me about 10 min/chip to remove the color / baked in dirt from the clay chips with a magic eraser, dish soap and a hard sponge.

So in conclusion:

Don't use water / steam to heat up the chips.

Use clean ceramic blanks to make sure, no color gets transferred.

Similar threads

- Replies

- 5

- Views

- 370

- Locked

- Replies

- 4

- Views

- 408

- Locked

- Replies

- 7

- Views

- 478

- Replies

- 7

- Views

- 285