Yesssss nice work Dan. Thcs next please

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bicycle Tires: Has anyone tried to refurbish these chips? (2 Viewers)

- Thread starter charitycase

- Start date

RivieraDanny

Royal Flush

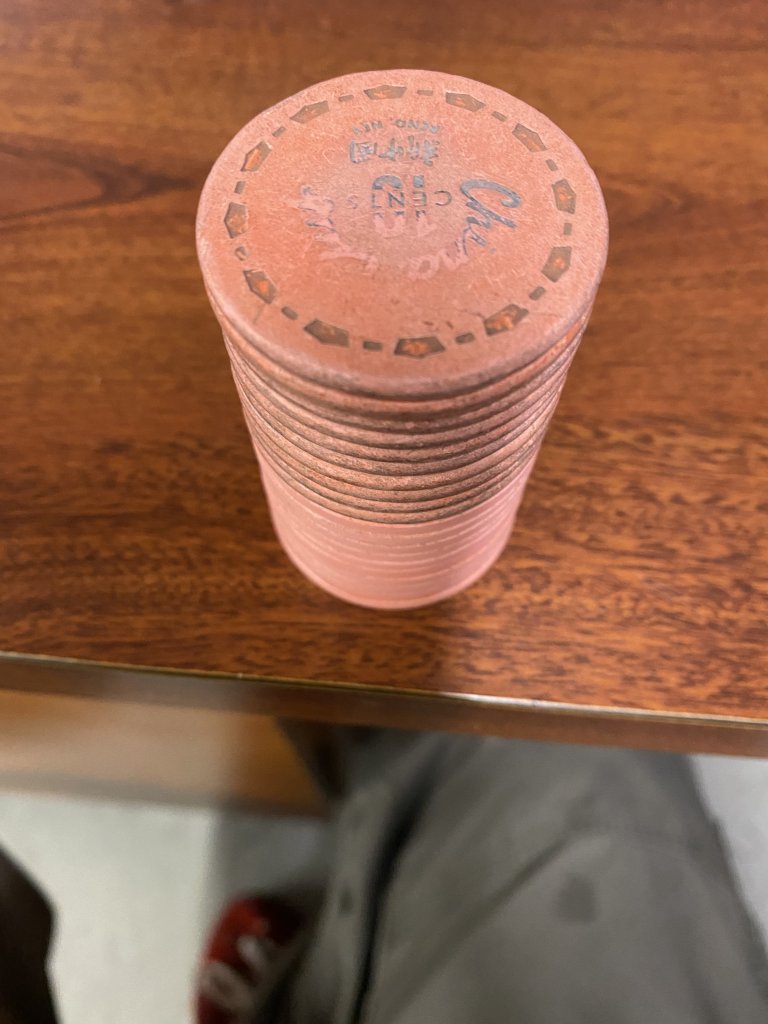

I'd assume that there is many DIY tricks to accomplish this. I'm using a number of modified pieces of equipment, doing multiple chips at once. As you can see and as @liftapint mentions sorting is the hardest part. Chips if like thickness to be run at a time. The attached picture shows the top chip of the completed barrel has worn, like many do, unevenly. Ie. one side of the chip is full thickness and the opposite side is measurably thinner. Not sure how this happens but there has to be an expectation that chips that are as bad as the NC $1 casino used can only be brought back so far. My modified machine can hold 2 barrels at a time if I try! Lol. At @JeepologyOffroad request I’m going to the shop with some thc’s. For the record bike tire RHC will not endure my lab!! Although I haven’t tried cause I have no bike tire rhc’s.So what does turning setup look like? 1 chip at a time or many at once? How are you holding them?

Last edited:

RivieraDanny

Royal Flush

My system auto corrects the alignment for the most part. But yes sorting into 3 conditions is where I'm at Condition 1: almost or stand on edge even wear, Condition 2: Low bike tire, somewhat even wear. Condition 3: full on bike tire this ass chips otherwise known as rejects. These NC 1's are ranging from 1-3 and about 25-30% will be untreatable. Not acceptable loss unless you can get 1000-1500 of them and hope to get 3-6 Excellent racks. 3-6 Very good - good racks and the rest re-inflated bike tires less round than they were!!! LOL!!!One important thing is to sort the chips in a batch into the most similar condition as possible. And line them up as exactly as possible.

RivieraDanny

Royal Flush

meh..... Somewhat true. Sorting is more important.. Not as much material comes off as one thinks... Chip thickness and even wear is more an issue than varying diameters. While the machine I use is "Lathe Like" yeah just using a lathe would be difficult!I spoke to my good friend who runs Tackett Game Calls about refurbishing some chips on a lathe. His feedback was interesting:

There are a handful of challenges. One is getting all the chips together and perfectly stacked. Another is getting them to stay together while on the lathe. Yet another is getting them perfectly centered between the lathe spindles so they spin true.

We discussed the possibility of some type of temporary, non-residue adhesive (like this maybe?) to hold them together while sandwiching them between a couple of blocks of wood. Getting all the chips centered is still an issue, and the turning process is going to remove quite a bit of material.

All chips will need to be turned to the diameter of the worst one of the bunch. So while they'll likely have varying degrees of wear, they all be machined to the lowest necessary thickness. So some chips will be unnecessarily shrank in the interest of consistency.

As has already been mentioned, achieving uniformity would be difficult from one batch to another. Even if you were somehow able to turn 100 chips at a time, you're almost certainly going to have diameter variances from one rack to the next - and once they were all mixed together it would probably be very noticable.

All that said, he said he'd be willing to try it when hunting season in MI ends. I don't own any chips in poor condition, but if anyone cares to send along some sacrificial lambs, I'll see what we can work out.

RivieraDanny

Royal Flush

I may file a patent on this!!!!!!!!!!!!! May be on to something!! Love my engineer son!

It would be a really great service if you could refine the process to a point that it doesn't change the diameter a noticeable amount, and really squares up the edges (and restores color, in some cases like Nevada Lodge). And if it's not *too* labor intensive so that it could be done on a semi-large scale, that would be a really great thing. Especially when a set has 1 denom that is so much more worn than the other denoms in the set.I may file a patent on this!!!!!!!!!!!!! May be on to something!! Love my engineer son!

It absolutely does, yes!Appreciate you risking your own chips for the science on all of this.

Would you say your method is helping with color variation at all? Hard to tell from the pics.

RivieraDanny

Royal Flush

What can the doctor do?

1. As Genie in Aladdin said..... No you can't bring the dead back to life.....

2. Remove large flea bites. They will still appear as nicks on the finished chip.

3. Restore edge color by up to 99.9%

4. Restore stand on slightly rounded edge chips to like new condition without removing as much chip as you would think.

5. restore no-stand rounded edges to stand on edge condition.

More to come I'm only a day into this experiment, a few hundred dollars, and minimal supplies....

We'll figure this out sooner than later!

1. As Genie in Aladdin said..... No you can't bring the dead back to life.....

2. Remove large flea bites. They will still appear as nicks on the finished chip.

3. Restore edge color by up to 99.9%

4. Restore stand on slightly rounded edge chips to like new condition without removing as much chip as you would think.

5. restore no-stand rounded edges to stand on edge condition.

More to come I'm only a day into this experiment, a few hundred dollars, and minimal supplies....

We'll figure this out sooner than later!

RivieraDanny

Royal Flush

Yes the white is blue again! evenly! only us NC $1 owners know what we mean here! But as you know some are white on the face edges now too, we cant fix that. I call it the Halo.It absolutely does, yes!

Marius L

4 of a Kind

Well done. Following for more uptdates as you go!

RivieraDanny

Royal Flush

As you can see by the last pic there is no noticeable size difference. But as mentioned some chip material is gone and a bike tire will never be a mint chip! But I think 99.9% of us can live with these results!! LOL!

12thMan

Full House

Holy F. Wow. That also makes me want the granny!!!!!View attachment 793680

View attachment 793680View attachment 793681View attachment 793679

As you can see by the last pic there is no noticeable size difference. But as mentioned some chip material is gone and a bike tire will never be a mint chip! But I think 99.9% of us can live with these results!! LOL!

This is an awesome project, congrats on getting to where you are and good luck on taking it further.

Marius L

4 of a Kind

Bike tyres are the new mint! Can you put them on top of each other and try to catch some photos to see the size difference? Mint chips vs bike tires vs lathed all in one stack would be ideal!

Really impressive by the looks of it. Maybe I should make a wanted ad for some worn GV primary $5a.... lol

Really impressive by the looks of it. Maybe I should make a wanted ad for some worn GV primary $5a.... lol

RivieraDanny

Royal Flush

I am confident enough to even put my new China club dimes through treatment! They’re all going to get it. As you can see by the top down stack there is no real noticeable difference in size after treatment. THC’s come good @JeepologyOffroad

Where do I send my money?

RivieraDanny

Royal Flush

Proprietary restoration method!!! I can make yours look good too!! Buy some!how did you get the chip face to look so much better?

Those results make me want a set of grannies!

Marius L

4 of a Kind

Wow

Sell me some!Proprietary restoration method!!! I can make yours look good too!! Buy some!

RivieraDanny

Royal Flush

Next up……..

These poorly neglected Bell Clubs.

These poorly neglected Bell Clubs.

Last edited:

I suppose I should find myself a bike tire set to buy

superchromix

Full House

Some nice work on this project!

RivieraDanny

Royal Flush

RivieraDanny

Royal Flush

Buy em up Send em over...Bike tyres are the new mint! Can you put them on top of each other and try to catch some photos to see the size difference? Mint chips vs bike tires vs lathed all in one stack would be ideal!

Really impressive by the looks of it. Maybe I should make a wanted ad for some worn GV primary $5a.... lol

Fantastic results!

Shaggy

Full House

This is the one I've been waiting for.

I suspect Cali Bell $5s may be too far gone. If you can barely make out the hat... prolly too far.

Similar threads

- Replies

- 44

- Views

- 2K

- Locked

Ends 02-16-24 at 8:00 PM Eastern Time

- Replies

- 0

- Views

- 369