MoscowRadio

Flush

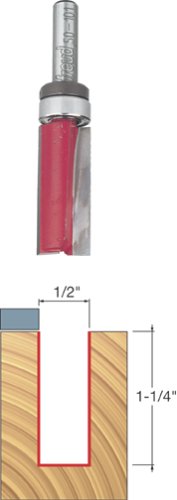

I've been having some difficulties with the bit shown below. The black ring above the bearing keeps coming loose shortly after I begin using it so it doesn't hold the bearing in place. I just wanted to see if any woodworkers here could help shed some light and guidance on how to move forward? I'd appreciate it greatly.