-

PCF is an Amazon Associate and an eBay Partner. If you make a purchase through one of our links, we may earn a commission at no extra cost to you. Thank you for your support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Complete drill press milling setup tutorial with details and links (1 Viewer)

- Thread starter Eloe2000

- Start date

GenghisKhan

Full House

- Joined

- Nov 7, 2014

- Messages

- 2,898

- Reaction score

- 4,723

Care to share pics of the chips? (Or saving them for a reveal later on?)

I made the same jig, and was almost dead on within 2 chips. I was off a hair, and wanted perfection, so I tried moving the jig a smidge.

Worst move ever. Don't be like me. Lol.

I got so frustrated at trying to get back centered, and same depth all around, I unplugged everything and haven't touched it in a while lol.

Will try to get back to it this week.

Might start the jig from scratch.

And this time will screw the top piece into the bottom piece once it's set.

I made the same jig, and was almost dead on within 2 chips. I was off a hair, and wanted perfection, so I tried moving the jig a smidge.

Worst move ever. Don't be like me. Lol.

I got so frustrated at trying to get back centered, and same depth all around, I unplugged everything and haven't touched it in a while lol.

Will try to get back to it this week.

Might start the jig from scratch.

And this time will screw the top piece into the bottom piece once it's set.

chrismurda

Flush

Home Depot, Lowe’s and Harbor Freight don’t sell poker chip milling kits for those of us who are not as savvy?

Eloe2000

Straight Flush

Home Depot, Lowe’s and Harbor Freight don’t sell poker chip milling kits for those of us who are not as savvy?

Unfortunately not, but I know a guy! Hint: @Josh Kifer

But if enough of us by the stuff from Amazon maybe it will start bundeling the items like it does for ultrasonic cleaners + salad spinners + TSP.

Wha?Unfortunately not, but I know a guy! Hint: @Josh Kifer

But if enough of us by the stuff from Amazon maybe it will start bundeling the items like it does for ultrasonic cleaners + salad spinners + TSP.

Uh, there isn't any secret tricks. Everything I learned was off this forum. Just gotta read a bit and toss in the money.

Eloe2000

Straight Flush

Wha?

Uh, there isn't any secret tricks. Everything I learned was off this forum. Just gotta read a bit and toss in the money.

Haha... I meant I know a guy who can do the milling for him/her if they aren’t mechanically savvy and don’t want to do it themselves. Just trying to send people your direction because of your awesome work.

Haha... Thank ya buddy!Haha... I meant I know a guy who can do the milling for him/her if they aren’t mechanically savvy and don’t want to do it themselves. Just trying to send people your direction because of your awesome work.

Care to share pics of the chips? (Or saving them for a reveal later on?)

I made the same jig, and was almost dead on within 2 chips. I was off a hair, and wanted perfection, so I tried moving the jig a smidge.

Worst move ever. Don't be like me. Lol.

I got so frustrated at trying to get back centered, and same depth all around, I unplugged everything and haven't touched it in a while lol.

Will try to get back to it this week.

Might start the jig from scratch.

And this time will screw the top piece into the bottom piece once it's set.

Most of them are on centre, others are not. If they are off a mm I don't sweat it. You can see in @Eloe2000 s rainbow picture a few are off a mm as well.

It's a futile battle. Because if your goal is to center one, you need to remount and center Every chip. Period. You center your jig, and it'll minimize the centering issue across the board. At least with the drill method I use, I've found most are a just a hint off center naturally.Most of them are on centre, others are not. If they are off a mm I don't sweat it. You can see in @Eloe2000 s rainbow picture a few are off a mm as well.

This. No way to avoid it with clay chips that have some variance.It's a futile battle. Because if your goal is to center one, you need to remount and center Every chip. Period. You center your jig, and it'll minimize the centering issue across the board. At least with the drill method I use, I've found most are a just a hint off center naturally.

Even with a CNC it’s not 100% perfect... but pretty damn close

Even with a CNC it’s not 100% perfect... but pretty damn close

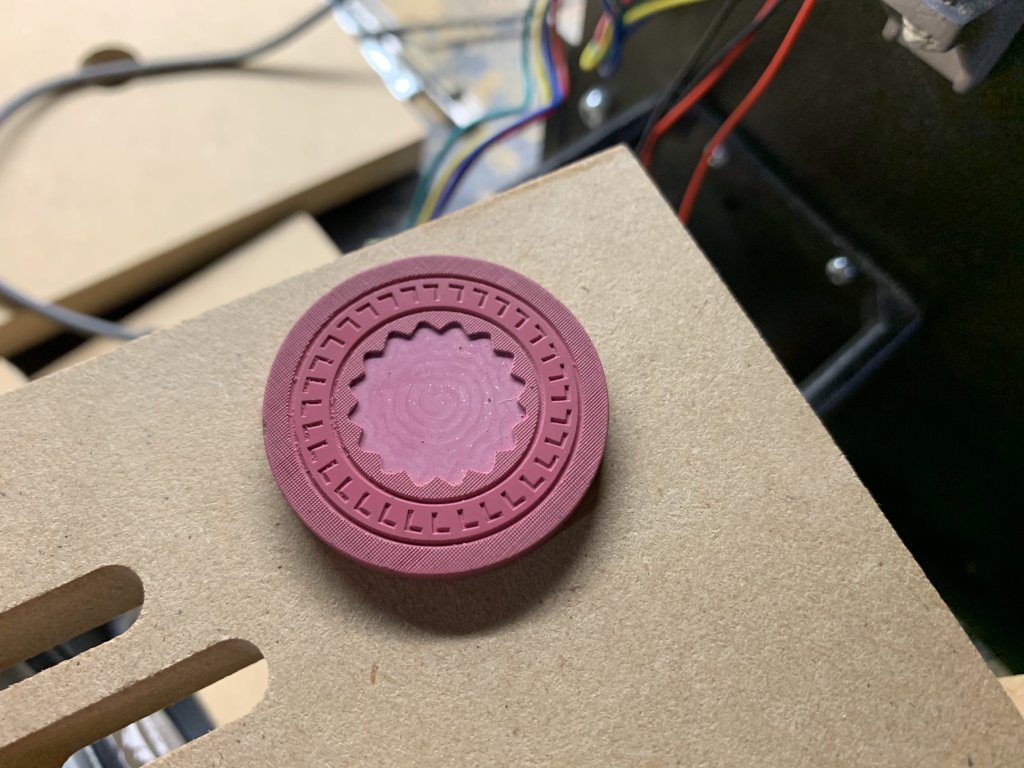

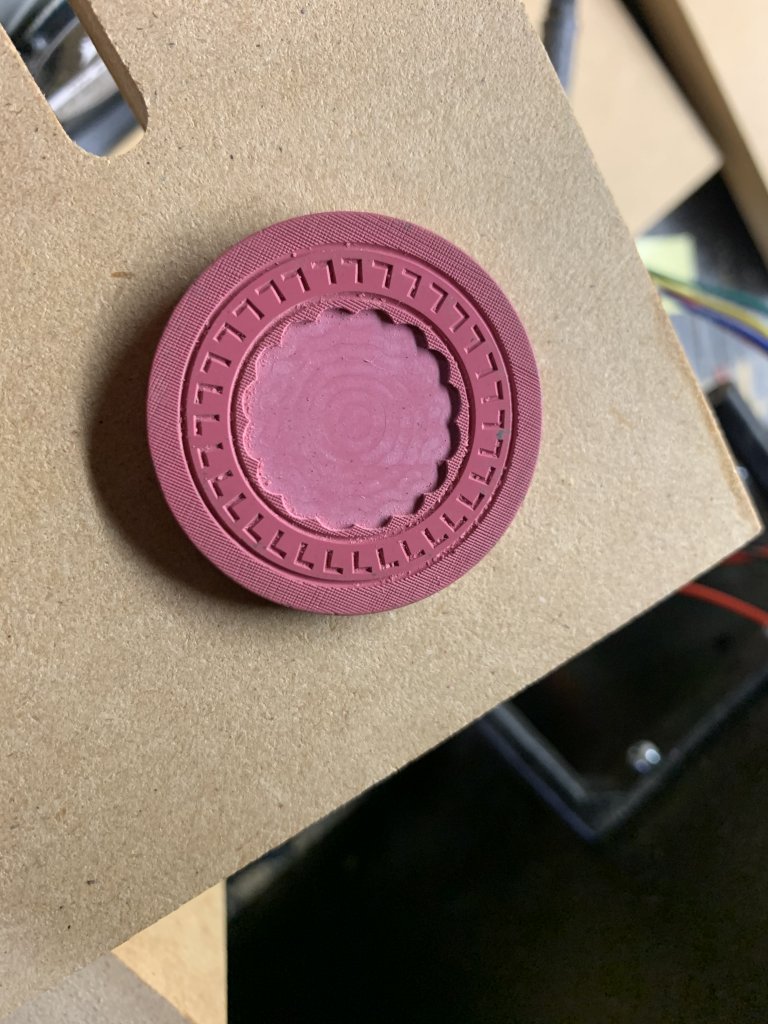

View attachment 465466View attachment 465463

View attachment 465464

View attachment 465467

Nice work!

Eloe2000

Straight Flush

Yeah, you have to realize how frequently Paulson themselves are off on inlays and stamps. Go ahead and check out a rack closely and your OCD will get triggered. Sometimes the inlays and stamps are off or sometimes they may be dead center but the mold is off so the inlays and stamps appear off center when they are not.

GenghisKhan

Full House

- Joined

- Nov 7, 2014

- Messages

- 2,898

- Reaction score

- 4,723

I keep forgetting this fact. Stupid me. I kept thinking it's like my chips are oval....they probably are! Lol.

Eloe2000

Straight Flush

I keep forgetting this fact. Stupid me. I kept thinking it's like my chips are oval....they probably are! Lol.

yeah you have to be willing to have some tolerance of variation realizing you are probably even more accurate than Paulson is. If you micro adjust for each chips you will drive yourself nuts. Your jig isn’t moving it’s the chips that vary.

So what I actually do is eyeball chips in each rack before I mill them. Generally I have found they are usually either all spot on (maybe a newer Paulson process?) or some that all seem to be off by the same amount (drunk press operator or more likely the initial placement of the mold or stamp dye etc was a hair off). If they are all slightly off them I will center my press on the center of the stamp which means the jig is slightly off center of the chip itself. And then as I mount each new chip I will place it in a way that I know it will line up. So for example I will set the jig so I know the stamp is closer on one edge I know to place that close edge of the stamp towards the front edge of the jig etc.

This is more of a problem with large stamps or inlays that are actually the full 7/8” and not smaller. Starbursts are close to 7/8” and most inlays are actually exactly 7/8” so precision is important. Counterintuitively when I am millingninlays I have taken to setting the jig very slightly off (less than 1mm) with the expectation that I will rotate the chip in the jig and hit it a second time. This essentially creates an oval recess but it is imperceptible and ensure I remove the entirety of the inlay.

markleteenie

4 of a Kind

I love the tutorial! Thank you.

I am going to be setting up a milling jig soon, maybe end of summer. But before then, I'm ultra sonic cleaning and even flattening some of my warped chips. I was going to oil them to see the colors even out (after the ultra sonic bath).

Here's the question: Do you guys usually mill the chip unoiled, or oiled and then have to re-oil the chip, or am I over-thinking the situation and any step order is fine?

Note: I know in order to take a @Gear label, if the inlay recess is oiled, the chip has to completely absorb the oil before a label can adhere properly.

I am going to be setting up a milling jig soon, maybe end of summer. But before then, I'm ultra sonic cleaning and even flattening some of my warped chips. I was going to oil them to see the colors even out (after the ultra sonic bath).

Here's the question: Do you guys usually mill the chip unoiled, or oiled and then have to re-oil the chip, or am I over-thinking the situation and any step order is fine?

Note: I know in order to take a @Gear label, if the inlay recess is oiled, the chip has to completely absorb the oil before a label can adhere properly.

Overthinking. Lol.I love the tutorial! Thank you.

I am going to be setting up a milling jig soon, maybe end of summer. But before then, I'm ultra sonic cleaning and even flattening some of my warped chips. I was going to oil them to see the colors even out (after the ultra sonic bath).

Here's the question: Do you guys usually mill the chip unoiled, or oiled and then have to re-oil the chip, or am I over-thinking the situation and any step order is fine?

Note: I know in order to take a @Gear label, if the inlay recess is oiled, the chip has to completely absorb the oil before a label can adhere properly.

I don't like milling oiled chips tho, makes the scraps stick to everything, including the chip. Makes more cleanup sometimes.

Here's the question: Do you guys usually mill the chip unoiled, or oiled and then have to re-oil the chip, or am I over-thinking the situation and any step order is fine?

I clean and oil my chips AFTER I mill them. Then just let them dry thoroughly before applying the labels. Here are some I did that i posted earlier in this thread.

Eloe2000

Straight Flush

I love the tutorial! Thank you.

I am going to be setting up a milling jig soon, maybe end of summer. But before then, I'm ultra sonic cleaning and even flattening some of my warped chips. I was going to oil them to see the colors even out (after the ultra sonic bath).

Here's the question: Do you guys usually mill the chip unoiled, or oiled and then have to re-oil the chip, or am I over-thinking the situation and any step order is fine?

Note: I know in order to take a @Gear label, if the inlay recess is oiled, the chip has to completely absorb the oil before a label can adhere properly.

Mill > ultrasonic > label > oil

And if I am not mistaken I believe that is Gears recommendation as well. But yes it is fine to label after oiling, you just have to wait a week or two to let it absorb. They tend to get a little dirty through milling which is why I clean them after.

The only really important part in terms of order is making sure you have a clean dry surface for the adhesion of the label. Because if you do that right they will last indefinitely. But if that gets screwed up and oil mixes with that adhesive I would hate to deal with the time and expense of reordering new labels.

Last edited:

markleteenie

4 of a Kind

Oh let me back up by saying for extremely dirty chips that I have to flatten, I figure I should flatten them. I know you should ultrasonic any chip before you flatten them, which is why I generally ultrasonic all chips that get to my house.

I don't mind ultrasonic cleaning them after the mill process too.

But it sounds like both of you are saying oil after everything. Do you see a problem with milling an oiled chip? (adequately soaked into the clay)

I don't mind ultrasonic cleaning them after the mill process too.

But it sounds like both of you are saying oil after everything. Do you see a problem with milling an oiled chip? (adequately soaked into the clay)

Don't mill before you flatten, or your gonna have a terrible time.Oh let me back up by saying for extremely dirty chips that I have to flatten, I figure I should flatten them. I know you should ultrasonic any chip before you flatten them, which is why I generally ultrasonic all chips that get to my house.

I don't mind ultrasonic cleaning them after the mill process too.

But it sounds like both of you are saying oil after everything.

markleteenie

4 of a Kind

Yeah that's why I was ultrasonic cleaning them first. As opposed to after milling.Don't mill before you flatten, or your gonna have a terrible time.

Eloe2000

Straight Flush

Oh let me back up by saying for extremely dirty chips that I have to flatten, I figure I should flatten them. I know you should ultrasonic any chip before you flatten them, which is why I generally ultrasonic all chips that get to my house.

I don't mind ultrasonic cleaning them after the mill process too.

But it sounds like both of you are saying oil after everything. Do you see a problem with milling an oiled chip? (adequately soaked into the clay)

No problem oiling before you mill. The milling will create a dry surface for the labels but there may be some oil transfer from handling and the milling may generate a slightly dusty surface. So just see how the surface is at that point and if it would be necessary to rinse them off or let the oil soak in further etc. Also I think you may loose some of the benefit of the oiling when you mill because of any light amount of dust. So you may find yourself wanting to re-oil.

Yeah that's why I was ultrasonic cleaning them first. As opposed to after milling.

Flatten first.

Then mill.

Then ultrasonic.

Then your choice will label or oil first. If label first, give some time for the epoxy to cure before carefully oiling. If oiling first, give some time for the oil to soak up before applying the label.

I like to oil prior to labelling because it takes less time - you don't have to be incredibly careful how you oil if there is no inlay/label already in the recess.

WhiteMamba1646

4 of a Kind

Also give urself a catcher of ur using a press... save time on cleaning

WhiteMamba1646

4 of a Kind

This is fricken awesome! Makes me want to invest in one myselfEven with a CNC it’s not 100% perfect... but pretty damn close

View attachment 465466View attachment 465463

View attachment 465464

View attachment 465467

Eloe2000

Straight Flush

Also give urself a catcher of ur using a press... save time on cleaning

View attachment 468800View attachment 468801

I’m going to have to up my cardboard box game apparently! Haha... awesome. So do I need to order a new recliner for the sake of my chip milling cleanliness?

WhiteMamba1646

4 of a Kind

Yes recliner is manditory in the milling process... so you can lounge between barrelsI’m going to have to up my cardboard box game apparently! Haha... awesome. So do I need to order a new recliner for the sake of my chip milling cleanliness?

markleteenie

4 of a Kind

Just ordered the bit. I think I'll probably make the safety guard too.

Similar threads

- Replies

- 35

- Views

- 3K

- Replies

- 15

- Views

- 521

- Replies

- 44

- Views

- 2K