Nymor

3 of a Kind

Hi all,

I built a desk last year - thread on another forum with pics - and really enjoyed the process and result so want to try for a poker table this year.

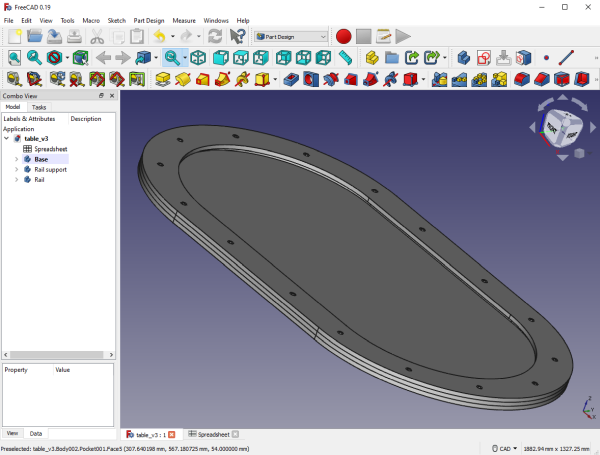

The main parts of the table will be CNCed so I can specify everything from the dimensions to corners and roundovers etc. My experience above has given me a lot of confidence as everything there came out to the mm and is gorgeous

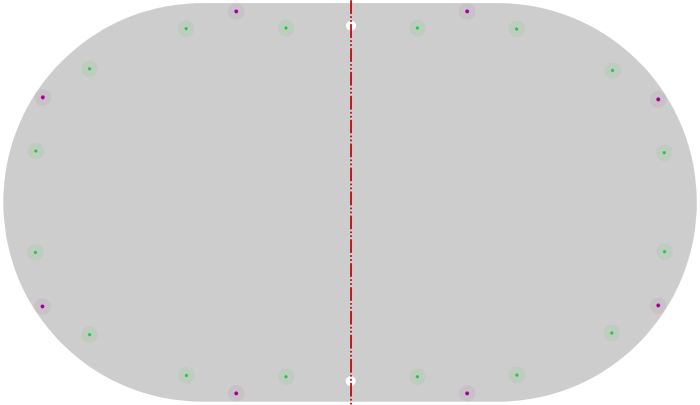

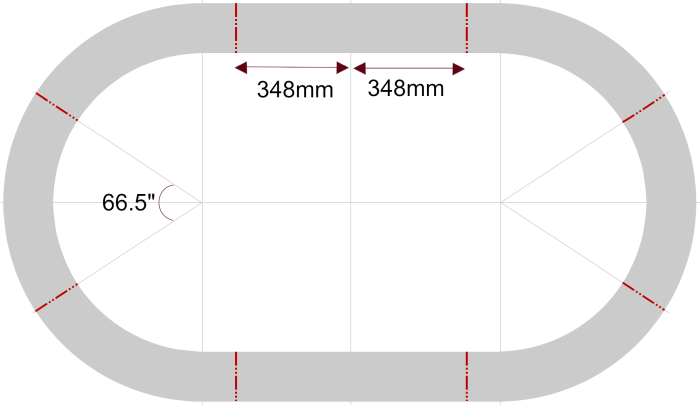

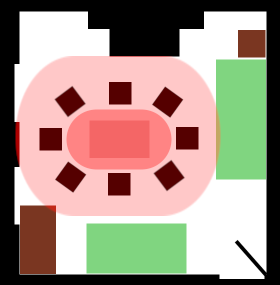

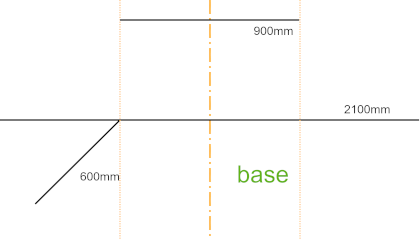

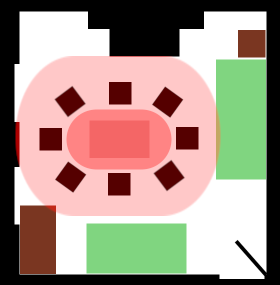

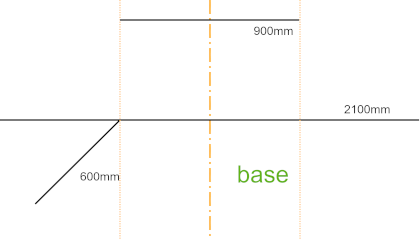

I live in a flat so space is restricted and the table needs to be "put away" when not in use but I don't mind if the table takes me 20mins to put together each time. I also want it to have as much room for each of the (8max) players. Going with outside rail 2100x1200mm (~83"x47") looks to be about spot on - a ~1800x900mm (~71"x36") playing surface, 150mm (6") rail raised 18mm (3/4") and allows a meter clearance around.

The design/build falls into 4 broad categories- the base, the playing surface, the rails and the lights - and I've got questions/decisions still to make on all of them.

The Base

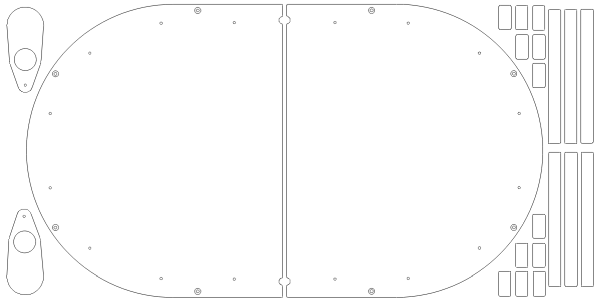

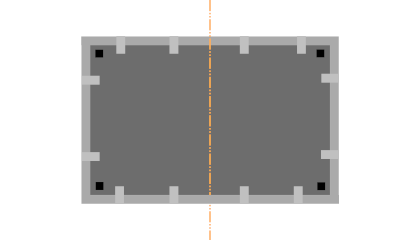

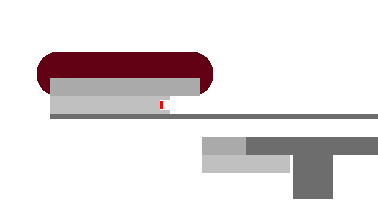

The base (in 2 parts) will be attached to an simple but sturdy IKEA dining table (1200mm x 750mm)

by way of strengthening supports on the base

and wooden latches - these give an idea of that

Details of that may change but that's the general idea. It will be made to be very solid yet simple to put together - the base being in 2 pieces for storage. Once the rail and rail support are added the ~400mm overhang should be fine but I can drop an extra leg each end if worst comes to the worst.

Currently looking at 18mm (3/4") plywood for the base but may go to 24mm (1").

The Playing Surface

While the base is in 2 bits the playing surface can't be - I don't want a split in the middle. My first thoughts many moons ago was to buy a foldable - we use them at my pub league games and they're fine - but fancied something a bit better and for whatever I end up with to not look like a foldable but a proper table. Seeing all the stunning examples on PCF has closed the door on that route anyway now

The surface can't be permanently attached to base so either has to roll out or be unfurled in some way - the rail assembly will hold the surface in place. I think I have 3 options at the moment:-

1. Neoprene

A custom printed neoprene surface may be a good route but how/where to get that in the UK isn't completely clear to me. The french guys? the lithuanian company?

2. Foam and Speed Cloth

This is where I was going initially. Possibly have the (5mm closed cell) foam stuck to the base and just unfurl the speed cloth over each time I set up. No betting line with this but that's ok ... maybe? and some friends have said they find SSC a bit rough but it is fairly durable. Of the speed cloths I've seen I like the 2 colour red one the best but sourcing in the UK seems an issue.

... and then I saw Chanmans cloths ...

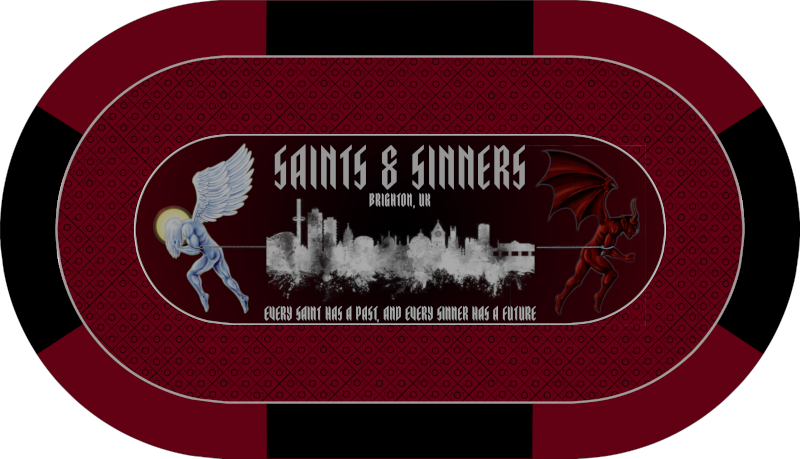

3. Chanman custom Cloth

If I can make this work it would become my preferred route - pushing the budget but they're lovely. If a cloth could be stuck to foam sheet and very loosely rolled without coming away that would work (specific foam and adhesive?) - or if, again, the foam was stuck to the base and I just unfurl, position and clamp the cloth in place with the rail (no adhesive) then I'd be good with that also.

For both 2 & 3 I could cut to fit or have some extra over the edge to help with tensioning/positioning prior to rail attachment and also have accomodation for the bolts coming through to attach rail and rail suppport. As I say I don't mind if it takes me 20mins to setup - it'll probably be only once or twice a month.

The Rail

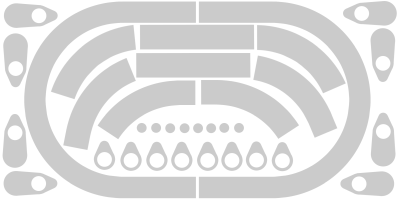

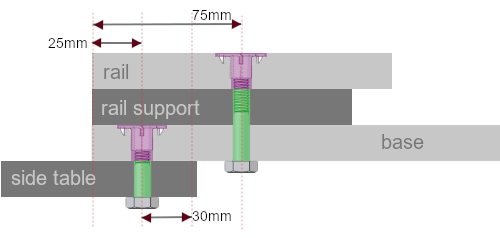

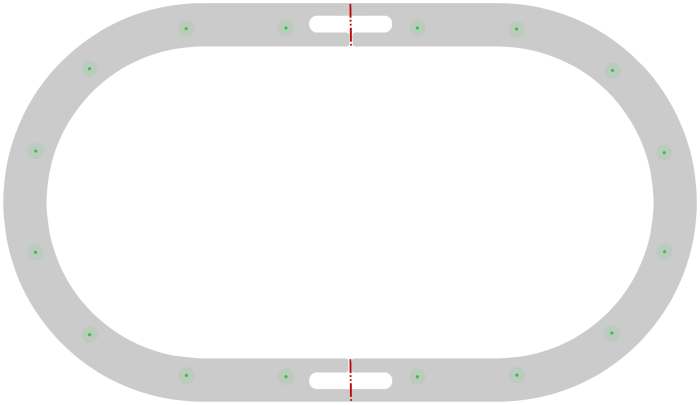

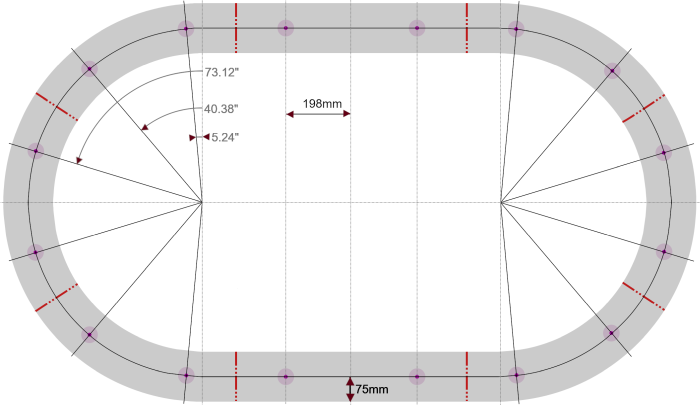

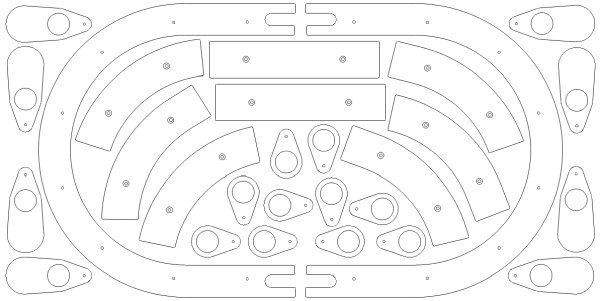

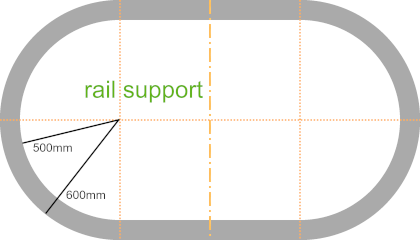

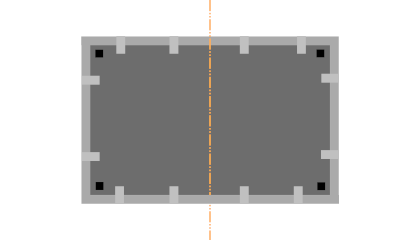

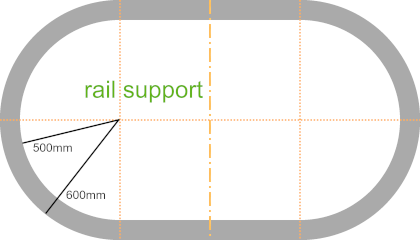

The 18mm (3/4") rail support would be between 10 & 12cm wide, sit on the cloth, house the lights and raise the rail. Hoping I can fix this in place with the same bolts that will fix the rail (with threaded inserts) but if I need to fix it separately then so be it. This will be in at least 2 pieces maybe 4 - the fewer the better as far as connecting the lights is concerned but not so they're flimsy when stored.

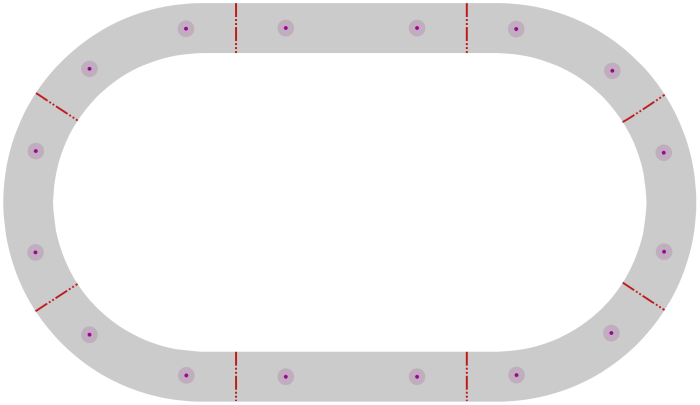

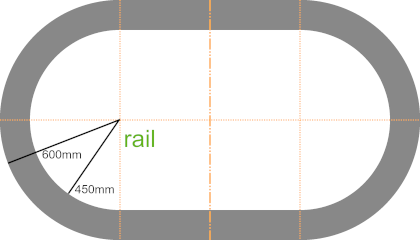

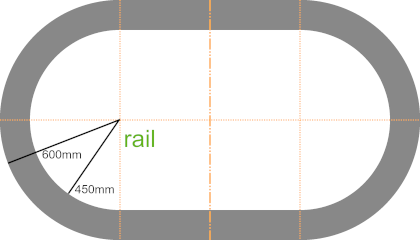

The rail itself is 15cm (6") width and also needs to be several sections. My favoured option at the momemt is to not try to hide the breaks and to not have any on the midline as that makes it look too much like a fold-up. Having 8 sections allows easier building and clearly defines the seating so everyone has plenty of room (~70cm/28") and no one is crowded (a pet hate of mine). I'm confident that with some upholstery tricks I can make the "ends" square and butt them against each other tightly enough they're nearly be as good as a full single rail.

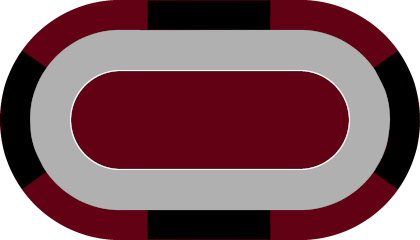

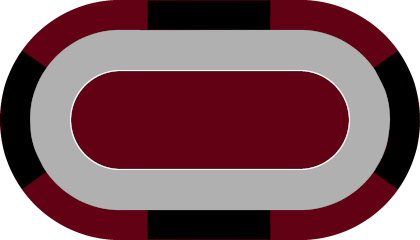

These will have 1" rail foam and faux suede. Getting black faux suede is easy - the dark burgundy, my current second colour, is proving tricky. The 2 colour scheme will work well if I can get a suitable dark colour to go with the black but if that fails I'll just do black all round.

I plan to fix each of the 8 sections, along with the rail support, to the base with 2 bolts from underneath the base and into threaded inserts in the rail. Hopefully 2 strong bolts per section should be plenty.

The Lights

To begin with I'm just going to have a dimmable warm white (3000k) string broken into however many parts the rail support config dictates. They'll sit in a routed lane on the inside edge of the rail support.

While looking for methods to diffuse the light that would be simple I came across EVA foam - used by cosplayers to make armour, for example, and to diffuse leds built into their costumes. It works well, looks good, is cheap/replaceable and if I oversize the height slightly I could wedge 1 or 2cm thick strips between the cloth and the underside of the rail infront of the leds. I'm going for more of a glow than a light if that makes sense. Once in place they'll be quite firm and be easy to take apart. (If that's a terrible idea then I can look at frosted perspex strips instead).

That's where I'm up to - I'm glad I've got all that off my chest

First order of business for me is to get a sanity check if possible on the overall plan and to decide on the playing surface as whatever that turns out to be may effect other details.

If you got this far thanks ... and opinions/recommendations etc very welcome

I built a desk last year - thread on another forum with pics - and really enjoyed the process and result so want to try for a poker table this year.

The main parts of the table will be CNCed so I can specify everything from the dimensions to corners and roundovers etc. My experience above has given me a lot of confidence as everything there came out to the mm and is gorgeous

I live in a flat so space is restricted and the table needs to be "put away" when not in use but I don't mind if the table takes me 20mins to put together each time. I also want it to have as much room for each of the (8max) players. Going with outside rail 2100x1200mm (~83"x47") looks to be about spot on - a ~1800x900mm (~71"x36") playing surface, 150mm (6") rail raised 18mm (3/4") and allows a meter clearance around.

The design/build falls into 4 broad categories- the base, the playing surface, the rails and the lights - and I've got questions/decisions still to make on all of them.

The Base

The base (in 2 parts) will be attached to an simple but sturdy IKEA dining table (1200mm x 750mm)

by way of strengthening supports on the base

and wooden latches - these give an idea of that

Details of that may change but that's the general idea. It will be made to be very solid yet simple to put together - the base being in 2 pieces for storage. Once the rail and rail support are added the ~400mm overhang should be fine but I can drop an extra leg each end if worst comes to the worst.

Currently looking at 18mm (3/4") plywood for the base but may go to 24mm (1").

The Playing Surface

While the base is in 2 bits the playing surface can't be - I don't want a split in the middle. My first thoughts many moons ago was to buy a foldable - we use them at my pub league games and they're fine - but fancied something a bit better and for whatever I end up with to not look like a foldable but a proper table. Seeing all the stunning examples on PCF has closed the door on that route anyway now

The surface can't be permanently attached to base so either has to roll out or be unfurled in some way - the rail assembly will hold the surface in place. I think I have 3 options at the moment:-

1. Neoprene

A custom printed neoprene surface may be a good route but how/where to get that in the UK isn't completely clear to me. The french guys? the lithuanian company?

2. Foam and Speed Cloth

This is where I was going initially. Possibly have the (5mm closed cell) foam stuck to the base and just unfurl the speed cloth over each time I set up. No betting line with this but that's ok ... maybe? and some friends have said they find SSC a bit rough but it is fairly durable. Of the speed cloths I've seen I like the 2 colour red one the best but sourcing in the UK seems an issue.

... and then I saw Chanmans cloths ...

3. Chanman custom Cloth

If I can make this work it would become my preferred route - pushing the budget but they're lovely. If a cloth could be stuck to foam sheet and very loosely rolled without coming away that would work (specific foam and adhesive?) - or if, again, the foam was stuck to the base and I just unfurl, position and clamp the cloth in place with the rail (no adhesive) then I'd be good with that also.

For both 2 & 3 I could cut to fit or have some extra over the edge to help with tensioning/positioning prior to rail attachment and also have accomodation for the bolts coming through to attach rail and rail suppport. As I say I don't mind if it takes me 20mins to setup - it'll probably be only once or twice a month.

The Rail

The 18mm (3/4") rail support would be between 10 & 12cm wide, sit on the cloth, house the lights and raise the rail. Hoping I can fix this in place with the same bolts that will fix the rail (with threaded inserts) but if I need to fix it separately then so be it. This will be in at least 2 pieces maybe 4 - the fewer the better as far as connecting the lights is concerned but not so they're flimsy when stored.

The rail itself is 15cm (6") width and also needs to be several sections. My favoured option at the momemt is to not try to hide the breaks and to not have any on the midline as that makes it look too much like a fold-up. Having 8 sections allows easier building and clearly defines the seating so everyone has plenty of room (~70cm/28") and no one is crowded (a pet hate of mine). I'm confident that with some upholstery tricks I can make the "ends" square and butt them against each other tightly enough they're nearly be as good as a full single rail.

These will have 1" rail foam and faux suede. Getting black faux suede is easy - the dark burgundy, my current second colour, is proving tricky. The 2 colour scheme will work well if I can get a suitable dark colour to go with the black but if that fails I'll just do black all round.

I plan to fix each of the 8 sections, along with the rail support, to the base with 2 bolts from underneath the base and into threaded inserts in the rail. Hopefully 2 strong bolts per section should be plenty.

The Lights

To begin with I'm just going to have a dimmable warm white (3000k) string broken into however many parts the rail support config dictates. They'll sit in a routed lane on the inside edge of the rail support.

While looking for methods to diffuse the light that would be simple I came across EVA foam - used by cosplayers to make armour, for example, and to diffuse leds built into their costumes. It works well, looks good, is cheap/replaceable and if I oversize the height slightly I could wedge 1 or 2cm thick strips between the cloth and the underside of the rail infront of the leds. I'm going for more of a glow than a light if that makes sense. Once in place they'll be quite firm and be easy to take apart. (If that's a terrible idea then I can look at frosted perspex strips instead).

That's where I'm up to - I'm glad I've got all that off my chest

First order of business for me is to get a sanity check if possible on the overall plan and to decide on the playing surface as whatever that turns out to be may effect other details.

If you got this far thanks ... and opinions/recommendations etc very welcome