http://www.pelican.com/us/en/pro/product/watertight-storm-hard-cases/medium-case/laptop-case/iM2400/

Just ordered this case. Looks interesting. I know its a company Pelican bought up and rebranded, but i like the dimensions.

Maybe a little smaller / lighter than the 1510

Should still be able to hold 1000 chips nicely and have room for cards/ buttons etc.

Also my goal is to have 1" of foam between each of the racks. i like the look of that better.

Will post pics once it gets here.

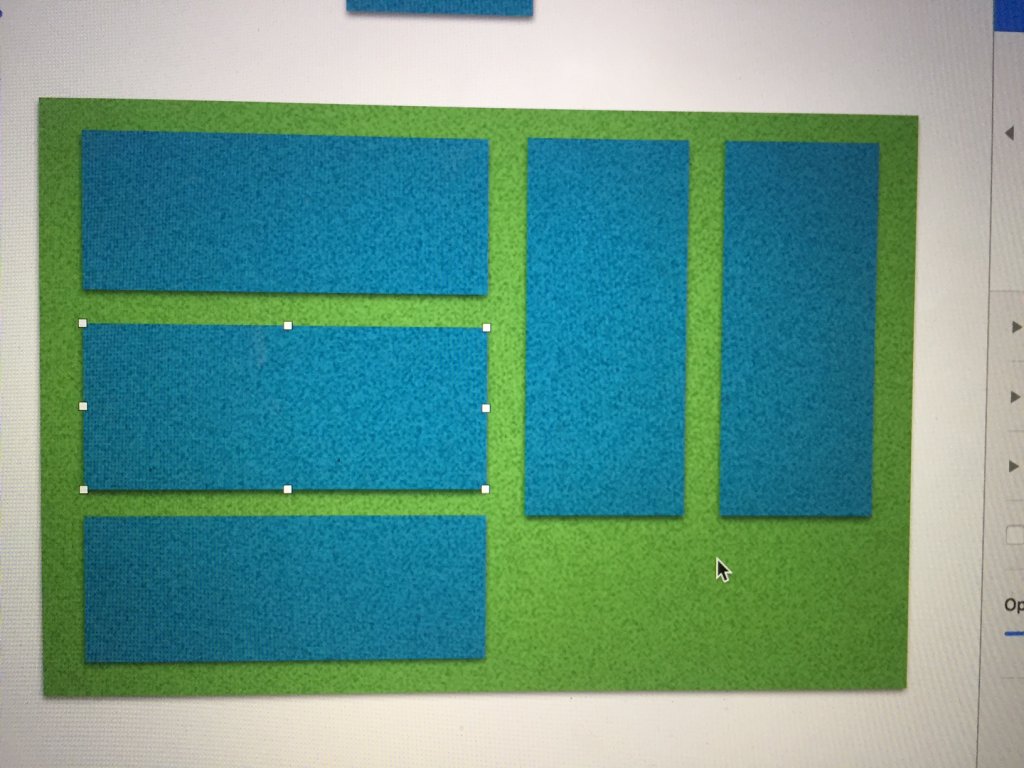

Im no good at sketch-up or saving word doc as a jpeg so heres a screen shot of the layout i intend to use.

Interior Dimensions are: 18" X 13" X 6.7"

Just ordered this case. Looks interesting. I know its a company Pelican bought up and rebranded, but i like the dimensions.

Maybe a little smaller / lighter than the 1510

Should still be able to hold 1000 chips nicely and have room for cards/ buttons etc.

Also my goal is to have 1" of foam between each of the racks. i like the look of that better.

Will post pics once it gets here.

Im no good at sketch-up or saving word doc as a jpeg so heres a screen shot of the layout i intend to use.

Interior Dimensions are: 18" X 13" X 6.7"

Last edited: