Jake14mw

Flush

Hi guys,

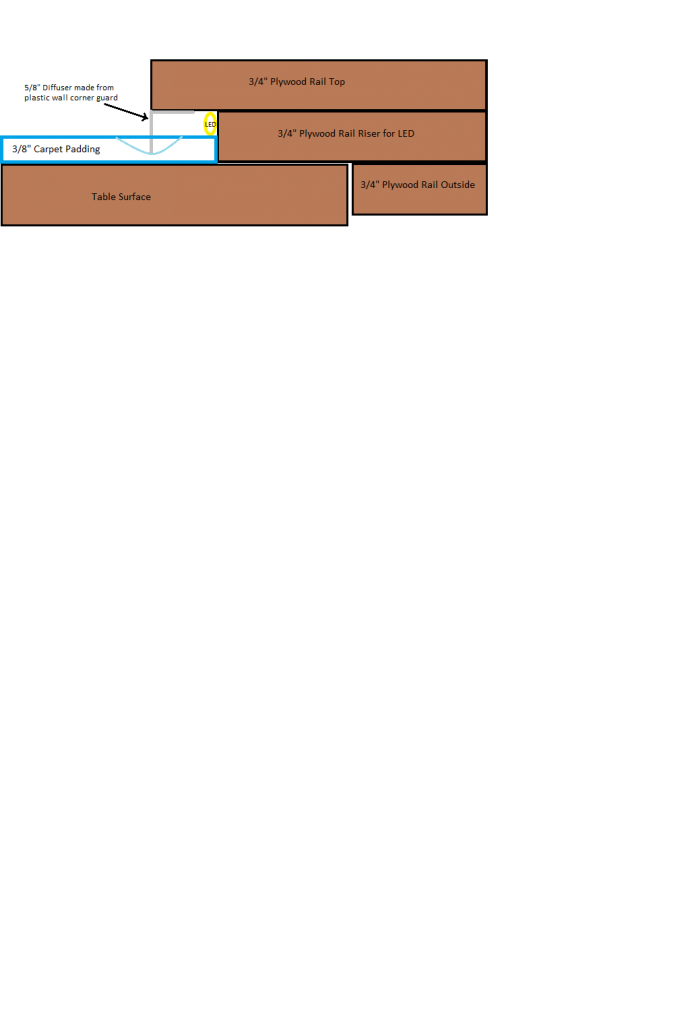

I am making a 58" Round table, no racetrack, LED lighted rail. To make things easier and cheaper for the LED lights, the diffuser is made from clear plastic wall corner guard material. (https://www.homedepot.com/p/Trimaco...tic-Corner-Guard-Residential-11834A/202061361). I am attaching a picture drawn to scale of what the rail build will look like. My issue is, since the plywood for the raised rail is 3/4" and the diffuser is 5/8", the diffuser will press down too far into the 3/8" padding. This is indicated in the picture by the light blue curved line. I guess two solutions for this could be 1) Add another 1/4" ply to the rail, or 2) run the padding all the way to the table edge. I was not planning on doing this because I thought it would be too "wobbly" with 3/8" padding. What do you guys think of this? How thick do you think the compressed padding under the rail would be? 1/8"? Any othe other suggestions would be appreciated. I hope the picture is clear.

I am making a 58" Round table, no racetrack, LED lighted rail. To make things easier and cheaper for the LED lights, the diffuser is made from clear plastic wall corner guard material. (https://www.homedepot.com/p/Trimaco...tic-Corner-Guard-Residential-11834A/202061361). I am attaching a picture drawn to scale of what the rail build will look like. My issue is, since the plywood for the raised rail is 3/4" and the diffuser is 5/8", the diffuser will press down too far into the 3/8" padding. This is indicated in the picture by the light blue curved line. I guess two solutions for this could be 1) Add another 1/4" ply to the rail, or 2) run the padding all the way to the table edge. I was not planning on doing this because I thought it would be too "wobbly" with 3/8" padding. What do you guys think of this? How thick do you think the compressed padding under the rail would be? 1/8"? Any othe other suggestions would be appreciated. I hope the picture is clear.