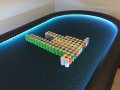

I just finished building my second poker table. I will add some pictures below.

Here are a few questions I have...

For some reason the table top feels harder than I expected. I used 1/4" closed cell foam and speed cloth that I ordered from "buildyourownpokertables.com". Also, the speed cloth is not very soft and I will probably replace it with a custom felt from @T_Chan . I just found him on the forums and his cloths look really nice.

My question is, has anyone ever used 1/2" foam on their table top instead of 1/4"? I'm not sure why my table feels so hard but I want it to have more cushion to it. I found some 1/2" foam on "amercangamingsupply.com". Has anyone ever used this?

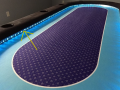

Also, what is the strip of plastic called that is put in front of the lights around the perimeter of the table? Where do I buy it? (I will add a picture of what I am talking about below.)

Thanks!

Here are a few questions I have...

For some reason the table top feels harder than I expected. I used 1/4" closed cell foam and speed cloth that I ordered from "buildyourownpokertables.com". Also, the speed cloth is not very soft and I will probably replace it with a custom felt from @T_Chan . I just found him on the forums and his cloths look really nice.

My question is, has anyone ever used 1/2" foam on their table top instead of 1/4"? I'm not sure why my table feels so hard but I want it to have more cushion to it. I found some 1/2" foam on "amercangamingsupply.com". Has anyone ever used this?

Also, what is the strip of plastic called that is put in front of the lights around the perimeter of the table? Where do I buy it? (I will add a picture of what I am talking about below.)

Thanks!

Attachments

-

IMG_2695.JPG134.9 KB · Views: 199

IMG_2695.JPG134.9 KB · Views: 199 -

IMG_2668.JPG108.4 KB · Views: 178

IMG_2668.JPG108.4 KB · Views: 178 -

IMG_2696.JPG140.3 KB · Views: 186

IMG_2696.JPG140.3 KB · Views: 186 -

IMG_2693.JPG137.8 KB · Views: 198

IMG_2693.JPG137.8 KB · Views: 198 -

IMG_2690.JPG194.5 KB · Views: 193

IMG_2690.JPG194.5 KB · Views: 193 -

IMG_2675.JPG103.3 KB · Views: 200

IMG_2675.JPG103.3 KB · Views: 200 -

IMG_2678.JPG110.2 KB · Views: 191

IMG_2678.JPG110.2 KB · Views: 191 -

Screen Shot 2020-04-08 at 4.19.23 PM.png1.1 MB · Views: 183

Screen Shot 2020-04-08 at 4.19.23 PM.png1.1 MB · Views: 183