You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fat Tire Lighted Rail Build Thread (4 Viewers)

- Thread starter Trihonda

- Start date

chipjoker

Flush

Very nice. I am thinking of making legs like this for my lit rail table. I like the black.

BukNaked36

Straight

Nice gloss finish - look great

Mental Nomad

Full House

I am thinking you may all be pedophiles.

chipjoker

Flush

L......O.........L

SHHHhhhhhhhhh....

SHHHhhhhhhhhh....

Beer for work on table = easy decision

Only issue I'm facing now... the steel kickplates were bent/sized by the builder for the peds without any finish... Adding the layers of finish has caused these kickplates to not fit. I'd have to rebend the metal (and even then it'd look bad IMHO). I'll try to get my lumber guy to get me new kick plates?

On a positive note, I feel I can start with routing the electrical, and once that's done, it's upholstery time (felt and rail).

On a positive note, I feel I can start with routing the electrical, and once that's done, it's upholstery time (felt and rail).

Can you mark the positions of the kickplates with an exacto knife? Then, bend a piece of wood and locate it at the edge and fasten in position. That would make it 1000X easier to sand the area of the kickplates down. I'm still down for a seat at this table for MTTD III.

Mental Nomad

Full House

That might be a pain in the ass, but it should work... how much depth do you need to reclaim?

If you mark the shape of the kick-plate tabs on the pedestals, chisel in the lines along the edges, and then sand off a layer, you should be able to mount the plates inset into the wood - like the hinges on a door.

It will be difficult and fraught with risk, but if it works, it could look better than good (to anyone that would inspect the qualify of work on a fricking kick-plate.)

If you mark the shape of the kick-plate tabs on the pedestals, chisel in the lines along the edges, and then sand off a layer, you should be able to mount the plates inset into the wood - like the hinges on a door.

It will be difficult and fraught with risk, but if it works, it could look better than good (to anyone that would inspect the qualify of work on a fricking kick-plate.)

manamongkids

Full House

random question....Only issue I'm facing now... the steel kickplates were bent/sized by the builder for the peds without any finish... Adding the layers of finish has caused these kickplates to not fit. I'd have to rebend the metal (and even then it'd look bad IMHO). I'll try to get my lumber guy to get me new kick plates?

On a positive note, I feel I can start with routing the electrical, and once that's done, it's upholstery time (felt and rail).

have you considered adding USB chargers mounted underneath the table?

I saw Maryland live added them recently and with the amount of time people spend on their phones, I think this would be a pretty bad ass addition. maybe like 4 total usbs

Picked up the bases. Badass.

Pics don't do them justice!

They went through a professional finisher. I provided paint and minwax polycrylic. However, I was told that the finisher opted to use their shop product, which included 3 coats of onyx varnish and a coat of their clear-coat finish.

As to the USB chargers, I toyed with this idea, but in reality, I'm not a casino. No player is ever that far away from a wall or bar outlet. It's never been an issue.

Pics don't do them justice!

They went through a professional finisher. I provided paint and minwax polycrylic. However, I was told that the finisher opted to use their shop product, which included 3 coats of onyx varnish and a coat of their clear-coat finish.

random question....

have you considered adding USB chargers mounted underneath the table?

I saw Maryland live added them recently and with the amount of time people spend on their phones, I think this would be a pretty bad ass addition. maybe like 4 total usbs

As to the USB chargers, I toyed with this idea, but in reality, I'm not a casino. No player is ever that far away from a wall or bar outlet. It's never been an issue.

Junior24xx

Straight

Man.... Can't wait to see final product. Great looking pedestals

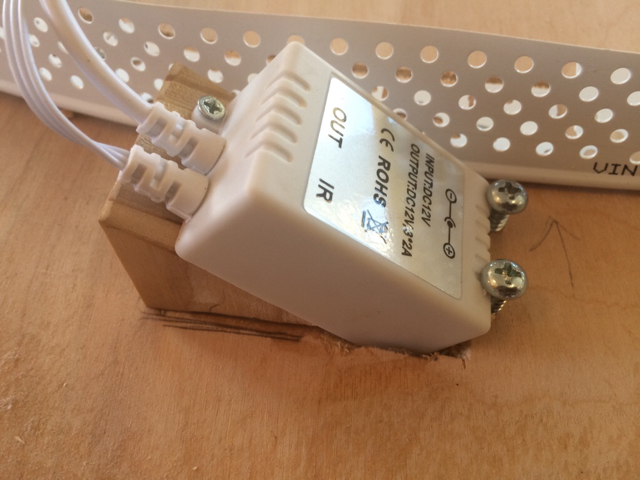

Worked on placement of the RF unit. I had to chisel out some of the base, so the RF unit would fit. I wanted a roughly 45d angle so the power cord wouldn't be as noticeable underneath, and would allow me to plug in the power without removing the rail each time.

Lumber guy does not believe in rounded edges (not necessary he says). I typically round my edges for better feel and ease of upholstery imho. I've played tables where the edges were not rounded, and would not bother me a ton as a player, but as a builder, I notice the sharp edge under the foam. (princess and pea thing?). Anyway, I also think that when forming the foam and stretching vinyl, it seems easier when I'm not doing so over a sharp corner, but I could be wrong?

Still on tap for today, installing LED's, felting the play surface, and upholstering the rail... Hmmm, that'll be almost done.

I'll need to touch up the melanine edging the builder installed on the base. At the seam, it's pulling away where it wasn't secured good enough. Need to snag some contact cement from the store though first.

I'll also have deco-nails to install on the base surface (underneath the vinyl rail). Planning 1.5" spacing.

Lumber guy does not believe in rounded edges (not necessary he says). I typically round my edges for better feel and ease of upholstery imho. I've played tables where the edges were not rounded, and would not bother me a ton as a player, but as a builder, I notice the sharp edge under the foam. (princess and pea thing?). Anyway, I also think that when forming the foam and stretching vinyl, it seems easier when I'm not doing so over a sharp corner, but I could be wrong?

Still on tap for today, installing LED's, felting the play surface, and upholstering the rail... Hmmm, that'll be almost done.

I'll need to touch up the melanine edging the builder installed on the base. At the seam, it's pulling away where it wasn't secured good enough. Need to snag some contact cement from the store though first.

I'll also have deco-nails to install on the base surface (underneath the vinyl rail). Planning 1.5" spacing.

Mental Nomad

Full House

but as a builder, I notice the sharp edge under the foam

I agree. Not everyone will notice or appreciate it, but lots will. Some will not realize WHAT they're appreciating, but they'll come away from your piece liking it more, just for unknown reasons.

it seems easier when I'm not doing so over a sharp corner, but I could be wrong?

I think you're right. If the material needs to slide left or right as you pull it over, a 90 degree corner is likely to hinder the movement, while a round-over lets it ease over the way it wants. It comes into play the most on the rounded ends of a project, not so much the straight edges.

Foam foam and more foam. Allowing the rail foam to dry thoroughly so I don't get nasty adhesive on my elec knife blades

Play surface foam.

Elec knife garage sale find for $1

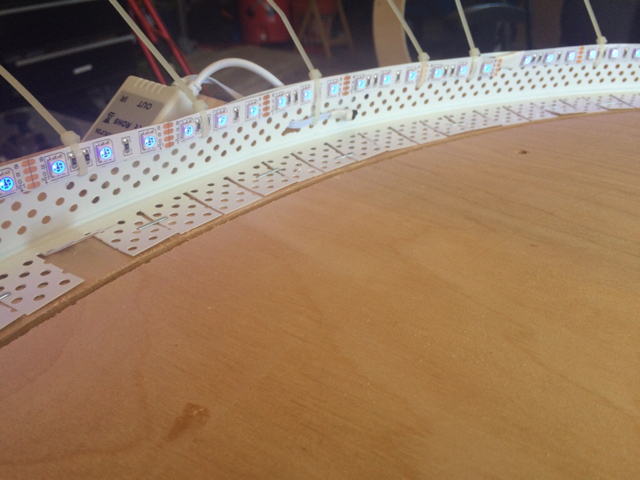

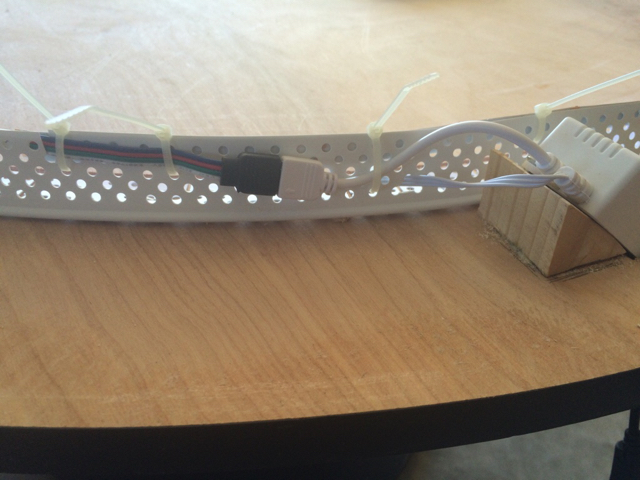

Attached the LEDs to the plastic. Used the 3m stickers on the back of the LEDs but my buddy also suggested using zip ties to make sure they stay put.

Routed my RF antennae through the plastic. It'll still have to fight through my aluminum diffuser for signal though...

Play surface foam.

Elec knife garage sale find for $1

Attached the LEDs to the plastic. Used the 3m stickers on the back of the LEDs but my buddy also suggested using zip ties to make sure they stay put.

Routed my RF antennae through the plastic. It'll still have to fight through my aluminum diffuser for signal though...

BukNaked36

Straight

Looks sweet!

Did you put the felt on yourself? I would have an incredibly hard time get that centered.

Did you put the felt on yourself? I would have an incredibly hard time get that centered.

Junior24xx

Straight

Looks epic.

Is the diffuser fixed to the playing surface?

Is the diffuser fixed to the playing surface?

tommythecat

Flush

Gaming Suede from ChanmanWhat kind of material is the custom felt? Is it actually felt?

Zathras

Sitting Out

That is looking really great!

derekdd23

Flush

This looks amazing!

I need to learn how to do this, but first I need a few extra hours in each day

I need to learn how to do this, but first I need a few extra hours in each day

There's a 1/2" grove in the base that the acrylic fits down into. The aluminum diffuser fits between the play surface and the Acrylic diffuser.

Really not all that happy with the rail upholstery. It's not my best work, but the raised rail is throwing me for a loop... That, and the table is wider, which is leaving me next to no material to get a good handhold for stretching the vinyl. Very minor wrinkles in the rail (seems on par with other tables I've seen about, but not really up to my standards). At this point, I'll just finish the rail vinyl, as I don't have a lot of choice since it's 1/2 done. However, I'm sure the wrinkles will irk the hell out of me. I'm sure few (if any) of my players will notice, or care.

Really not all that happy with the rail upholstery. It's not my best work, but the raised rail is throwing me for a loop... That, and the table is wider, which is leaving me next to no material to get a good handhold for stretching the vinyl. Very minor wrinkles in the rail (seems on par with other tables I've seen about, but not really up to my standards). At this point, I'll just finish the rail vinyl, as I don't have a lot of choice since it's 1/2 done. However, I'm sure the wrinkles will irk the hell out of me. I'm sure few (if any) of my players will notice, or care.

Erik, you should be able to go back and / pull staples / stretch material / re-staple / and get those pesky wrinkles to go away. Try using rubber-coated wide pliers to grasp the material if you can't get a good grip with your fingers. Assistance from a second set of hands is helpful, too.

Patience will prevail over wrinkles, and allow you to be irk-free.

Patience will prevail over wrinkles, and allow you to be irk-free.

Similar threads

- Replies

- 10

- Views

- 403

- Replies

- 17

- Views

- 780

- Replies

- 3

- Views

- 706

- Replies

- 11

- Views

- 280

- Replies

- 53

- Views

- 5K