Do you have a projected date in mind yet for when these might be in the store? I bought an Apache yesterday and looking to do the same as you - row of flat bottomed ones on the bottom, stacking ones up top. I've got 8Vs too, and as you know, there's really nothing out there to buy off the shelf...I've been printing racks for my 1200 chip 8V limit set and refining the rack design as I go. The bottom rack is flat on the bottom. I'll have a layer of those on the bottom of an Apache case, then 6 regular racks stacked on top. I'll be sharing the model soon, and I'll put the 71mm racks for the 8V China Clays in my store first. Then I'll move on to racks of other sizes.

These things stack like bricks!

View attachment 455459

-

PCF is an Amazon Associate and an eBay Partner. If you make a purchase through one of our links, we may earn a commission at no extra cost to you. Thank you for your support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My attempt at 3D printing racks (2 Viewers)

- Thread starter One Eyed Dollar

- Start date

One Eyed Dollar

Flush

Very soon! Maybe even this evening if I can get time to take pictures and add them to my store. Gotta run to the hardware store now and get a new storm door to fix my broken one. It's always something with the house...Do you have a projected date in mind yet for when these might be in the store? I bought an Apache yesterday and looking to do the same as you - row of flat bottomed ones on the bottom, stacking ones up top. I've got 8Vs too, and as you know, there's really nothing out there to buy off the shelf...

KingJames12

Sitting Out

That's rest neat! Might have to dust off the ol' 3D printer... Good job!

One Eyed Dollar

Flush

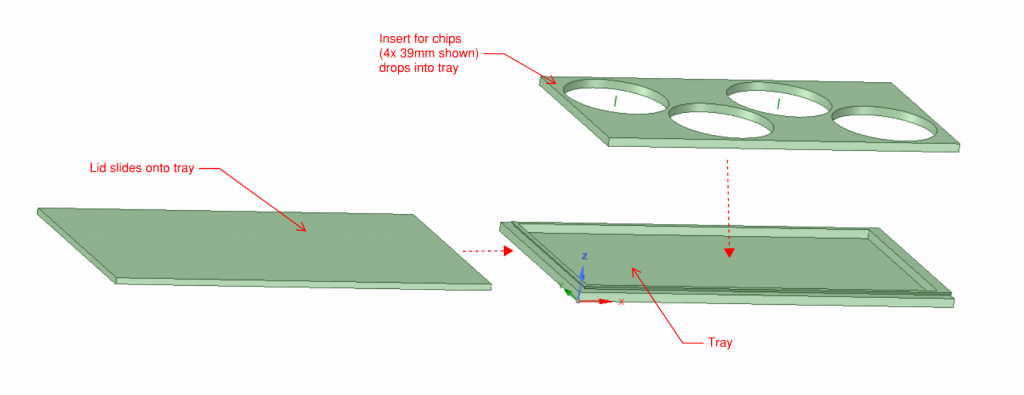

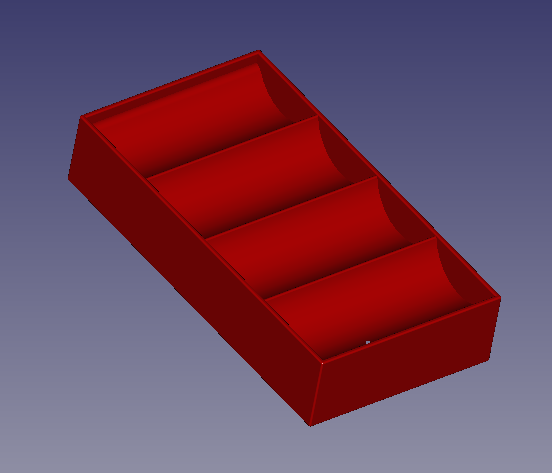

Brainstorming an idea here. Let me know if anyone thinks this would be a useful item. Shipping singles in an envelope is a pain, trying to keep it thin but protect the chippies. What about a reusable plastic sleeve to put the chips in?

I've dubbed it the Singles Shipping Sleeve. It consists of 3 parts: a tray, an insert to hold the chips, and a slid that slides onto the tray. I think this would provide good protection for the chips in transit, but I'll have to print one to see how flexible it is and if it would resist bending. I'm trying to keep it under 1/4" thick so it can be mailed as an envelope instead of a package.

I could make different inserts to hold 39mm or 43mm chips or some combination of sizes. I'm still thinking of ideas of ways of making that more customizable. That's why I'm thinking the insert would be separate from the tray, for flexibility of chip sizes for reuse.

I'm thinking there could be a few different sizes to fit standard size envelopes... I think #10 and #6-3/4 are the most common ones. This mockup is for a #6-3/4.

I've dubbed it the Singles Shipping Sleeve. It consists of 3 parts: a tray, an insert to hold the chips, and a slid that slides onto the tray. I think this would provide good protection for the chips in transit, but I'll have to print one to see how flexible it is and if it would resist bending. I'm trying to keep it under 1/4" thick so it can be mailed as an envelope instead of a package.

I could make different inserts to hold 39mm or 43mm chips or some combination of sizes. I'm still thinking of ideas of ways of making that more customizable. That's why I'm thinking the insert would be separate from the tray, for flexibility of chip sizes for reuse.

I'm thinking there could be a few different sizes to fit standard size envelopes... I think #10 and #6-3/4 are the most common ones. This mockup is for a #6-3/4.

JustinInMN

4 of a Kind

I probably would have bought some of these when I was shipping sample sets.

markleteenie

4 of a Kind

How much does the plastic insert weigh? That’s definitely a consideration.

Also for differences in size, the plastic chip protectors have the foam ring. Not sure if you can just buy that foam insert?

Also for differences in size, the plastic chip protectors have the foam ring. Not sure if you can just buy that foam insert?

MatthewTreeTree

Flush

One thing that I didn't include in my model is this little lip along the bottom of the sides of the Paulson racks. I tried to take a picture of it, but my phone's camera is lousy at macro photos. Does this little lip serve any purpose, like holding the racks in place in a birdcage or anything? I could add it to my model if there is some reason for it.

View attachment 380971

HELPS A LOT WITH GRIP

One Eyed Dollar

Flush

Yeah, the foam is a good idea. I'd thought about something like that, but I don't know where to source it.How much does the plastic insert weigh? That’s definitely a consideration.

Also for differences in size, the plastic chip protectors have the foam ring. Not sure if you can just buy that foam insert?

Looks like all the plastic parts together would weigh about 2.3 oz for this design.

markleteenie

4 of a Kind

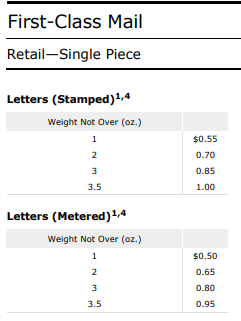

I'd like to just point out letter pricing per weight (from USPS website). Your 2.3oz doesn't include envelope, chip, additional tape.

I am not certain if there is a limit to a letter. Maybe 3.5oz?

I am not certain if there is a limit to a letter. Maybe 3.5oz?

One Eyed Dollar

Flush

Good points. With 4 chips that's probably at 3.7 oz plus envelope and tape. I'd have to experiment with a honeycomb pattern for the lid/tray to reduce weight. A foam insert would shave some weight off too.

I think you're better making this out of laser-cut foam board than 3d printing. It would be much lighter and just as rigid as thin plastic but with the added benefit of offering some shock resistance.

Now if you want an idea for a project, how about stack-able card trays? Something you can put two setups in and stack on top of each other with perhaps a lid or cover for the top?

Now if you want an idea for a project, how about stack-able card trays? Something you can put two setups in and stack on top of each other with perhaps a lid or cover for the top?

One Eyed Dollar

Flush

That's a good idea for weight reduction. I haven't worked with laser cutting or foam board (except for making lots of architectural models out of foam core with Xacto knives back in the day), but I see people doing lots of board game organizers with it. I don't know how durable it would be for repeated shipping, but maybe it would hold up.I think you're better making this out of laser-cut foam board than 3d printing. It would be much lighter and just as rigid as thin plastic but with the added benefit of offering some shock resistance.

Now if you want an idea for a project, how about stack-able card trays? Something you can put two setups in and stack on top of each other with perhaps a lid or cover for the top?

I have card trays that fit in birdcages now, and I'll have a version with lids soon. They can stack but they don't interlock. That wouldn't be hard to do. They hold the decks end-to-end to sit on a rack of chips though. Are you thinking like that or side-by-side?

JustinInMN

4 of a Kind

I'd like to just point out letter pricing per weight (from USPS website). Your 2.3oz doesn't include envelope, chip, additional tape.

I am not certain if there is a limit to a letter. Maybe 3.5oz?

View attachment 500779

Good points. With 4 chips that's probably at 3.7 oz plus envelope and tape. I'd have to experiment with a honeycomb pattern for the lid/tray to reduce weight. A foam insert would shave some weight off too.

At these sizes anyway you should be looking at "large envelope" pricing.

My sample sets of four were going at the 4-5 oz price I believe in a #6 3-4 bubble mailer. But large envelope goes to 13 oz, so not really a problem to add 2 oz to the weight, extra 40c for shipping.

One Eyed Dollar

Flush

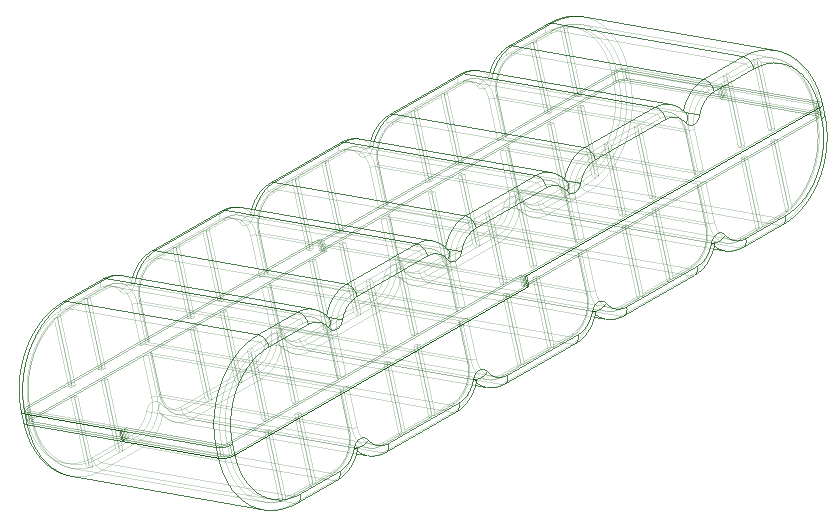

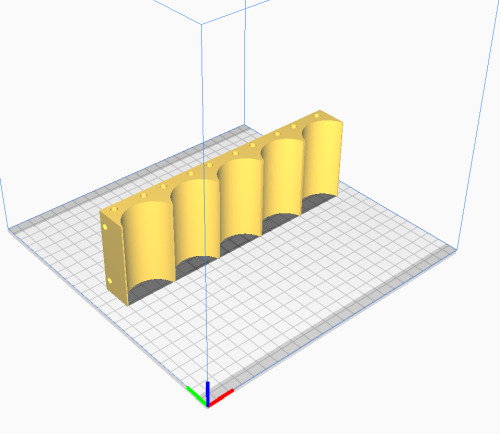

I've had multiple requests for spacers for Matsui racks, so I started working on that last night. I decided to model the rack itself as closely as I could first, and then use that as the basis for designing the spacers to fit.

The walls on these racks are very thin, so the chance of breakage would be pretty high I think if you tried to 3D print one. Plus you wouldn't be able to see the chips inside! But anyway this is how my model looks so far. I haven't added the circles top and bottom that help them stack together since that doesn't matter for the spacers.

My plan is to create a side spacer in different thicknesses so the chips can't slop back and forth, and a bottom spacer that holds 39mm chips without rolling around, and a combined one-piece side/bottom spacer.

The walls on these racks are very thin, so the chance of breakage would be pretty high I think if you tried to 3D print one. Plus you wouldn't be able to see the chips inside! But anyway this is how my model looks so far. I haven't added the circles top and bottom that help them stack together since that doesn't matter for the spacers.

My plan is to create a side spacer in different thicknesses so the chips can't slop back and forth, and a bottom spacer that holds 39mm chips without rolling around, and a combined one-piece side/bottom spacer.

Chiphuntr

3 of a Kind

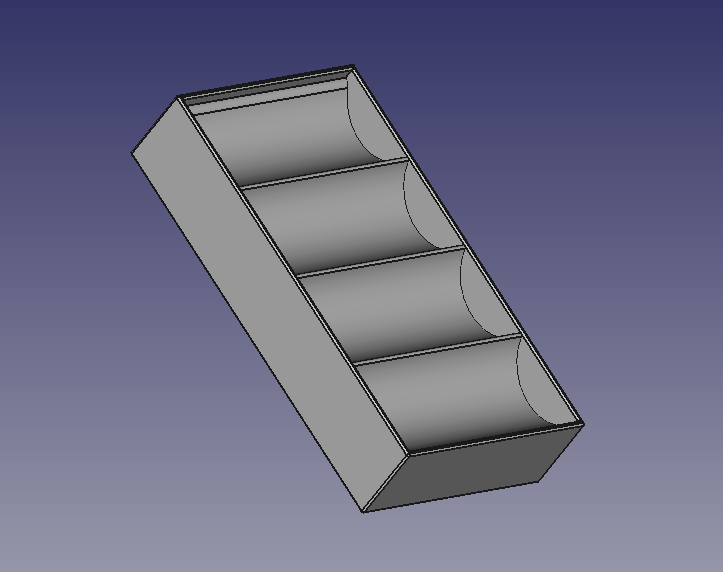

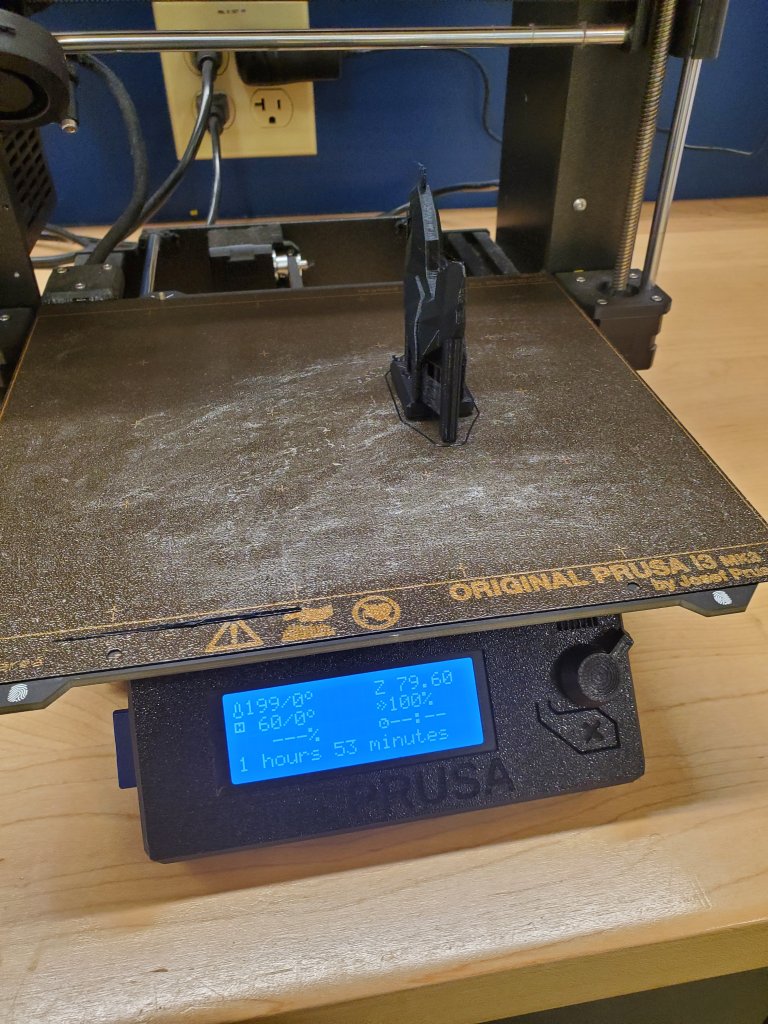

Here are some shots of the test print. The bottom walls did not print well, I think because I skimped too much on the support underneath. I decided to thicken the walls on the bottom part slightly too, and I'm running another test print with more support. Still working on some remixes with a recess for dealer buttons and other variations.

View attachment 389052

View attachment 389053

Here's a shot of the original for comparison and to show how it stacks:

View attachment 389056

Where did you get the original tray that stacks on top of chip racks?

One Eyed Dollar

Flush

I bought a clamshell chip case with some dice chips off craigslist, and the case came with a pair of those. I'm not sure of the original source for those cases, and we haven't been able to find anyone that sells the trays alone.Where did you get the original tray that stacks on top of chip racks?

mcguiles

3 of a Kind

have you ever attempted a dealer tray that can fit 43mm on each end and 39mm for the rest?

powderhousepoker

Waiting List

Just ordered a Ender Creality 3 V2 via a "Pre" Prime Day sale! Already have a small chip rack designed in FreeCAD but it's nothing special. Here's a pic. It's 4x25 for 39mm. Designed it to be something different, but we all know that 5x20 racks are the nuts. I plan to design a few racks for buy-ins, maybe some other random cool poker items, but nothing major. I've seen some interesting 3D printed ammo box inserts on here as well. Whatever your mind desires...plus a few hours of messing around with software. (I have yet to dial in my printer, or even set it up. So those hours included.) I guess I should be looking for upgrades towards that now...

2) You could create custom racks designed to hold starting stacks for tournaments.

edit: didn't read whole thread to notice question/comment already addressed (I'm new here)

Sparkynutz

Flush

I'll be printing some racks for bounty chips, seating chips, Dealer buttons shortly. What's the sensus on best printing direction?

I'm going to try a few the normal direction but thinking about making them on the side with one end printed seperate and glued on then inserted into another rectangle box to keep it all together.

What's the best glue?

I'll be using a 3d printer at the Library. They allow 6 hours of use free per week so this may take a while.

Here's a pic of the Rooster I'm making for a game similar to horse racing +2 cards and peices.

I'm going to try a few the normal direction but thinking about making them on the side with one end printed seperate and glued on then inserted into another rectangle box to keep it all together.

What's the best glue?

I'll be using a 3d printer at the Library. They allow 6 hours of use free per week so this may take a while.

Here's a pic of the Rooster I'm making for a game similar to horse racing +2 cards and peices.

I know that this comment is like 3 years old but on a quick glance I think the idea is good, for the chip tray leave it as but maybe make it a little thicker to accommodate a chip insert that is completely foam. For example you can get that cheapo hobby foam we use in my house for kids crafts, its also relatively thin. Then just cut the rectangle shape out of it, and then use an appropriate sized die to cut out the circle for a chip. Also this should cut down on the need for the filament and the print time for the actual insert. Hope that makes sense.Yeah, the foam is a good idea. I'd thought about something like that, but I don't know where to source it.

Looks like all the plastic parts together would weigh about 2.3 oz for this design.

Sparkynutz

Flush

Two failed prints and the 3rd was barely acceptable. The good news is I still got the dimensions locked down in the process.

I saw some racks with an insert printed on its side inside a box printed on its bottom. I liked it but didnt like how it looked uneven with my ocd so I plan on gluing the spacer on before putting it inside the outer box.

Stay tuned for the box

Has 1UP on each long side and the mushroom on each short side.

I saw some racks with an insert printed on its side inside a box printed on its bottom. I liked it but didnt like how it looked uneven with my ocd so I plan on gluing the spacer on before putting it inside the outer box.

Stay tuned for the box

Has 1UP on each long side and the mushroom on each short side.

Last edited:

Sparkynutz

Flush

This is the rack I speak of.

Pretty cool two tone tho So I'm doing mine sparkly silver inside with green outside.

Pretty cool two tone tho So I'm doing mine sparkly silver inside with green outside.

Sparkynutz

Flush

I plan on doing more of these single racks and twin racks of 10 for the dagger seating/bounty chips from latest group buy with a dagger on short end, Bounty on long end instead of the mushroom design and also in red/blue

And lastly twin 5 chip and a single 10 chip dealer button racks with some type of design on them as well.

And lastly twin 5 chip and a single 10 chip dealer button racks with some type of design on them as well.

Nymor

3 of a Kind

What's the sensus on best printing direction?

I'm going to try a few the normal direction but thinking about making them on the side with one end printed seperate and glued on then inserted into another rectangle box to keep it all together.

When I printed racks for my chip case, see sig for link to details, I printed the main part and the sides and ends separately - mainly because I was adding fabric around the parts but also because it was going to produce better prints. I'd probably still print in pieces even without the fabric requirement for those reasons.

As for direction I printed the main part is this orientation.

Doing it this way ensured the curved part was as smooth as it could be as the curve was printed on the horizontal.

What's the best glue?

The first time I had to glue parts together I used Gorilla superglue but it set far too fast to be practical - if you don't line up parts exactly first time you don't get a second chance. You can help yourself a lot by including biscuits and rods/holes etc, as I did in the part above, but sometimes you don't have a choice but to try and glue smooth surfaces together.

I now use

and it's perfect as far as I'm concerned - still quick but it gives you enough time to adjust your positioning and it never clogs ... seriously.

Sparkynutz

Flush

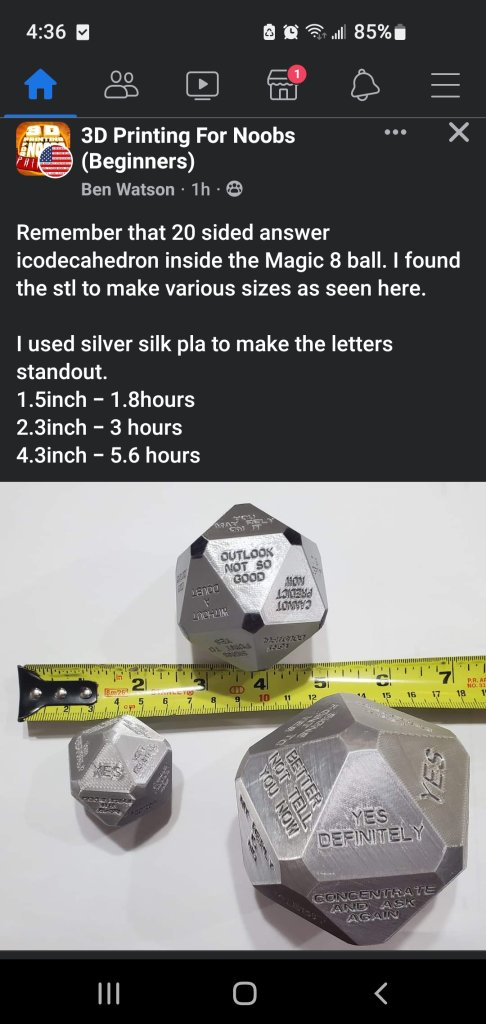

I forget where I saw it asked for an 8 ball with game types in it but this is close. could make the die that way with 20 games on it.

markleteenie

4 of a Kind

You could always do 8 games twice with 4 dealer’s choice spots… or something like that.

How about a roulette wheel? 38 games!

Nex

Flush

Requires precision far out of reach for a run-of-the-mill 3D printer and extra parts (bearings etc.). You're better off just buying a traditionally made roulette wheel instead of trying to print one.How about a roulette wheel? 38 games!

Similar threads

- Replies

- 1

- Views

- 171

- Replies

- 1

- Views

- 110

- Replies

- 0

- Views

- 178

- Replies

- 1

- Views

- 133