One Eyed Dollar

Flush

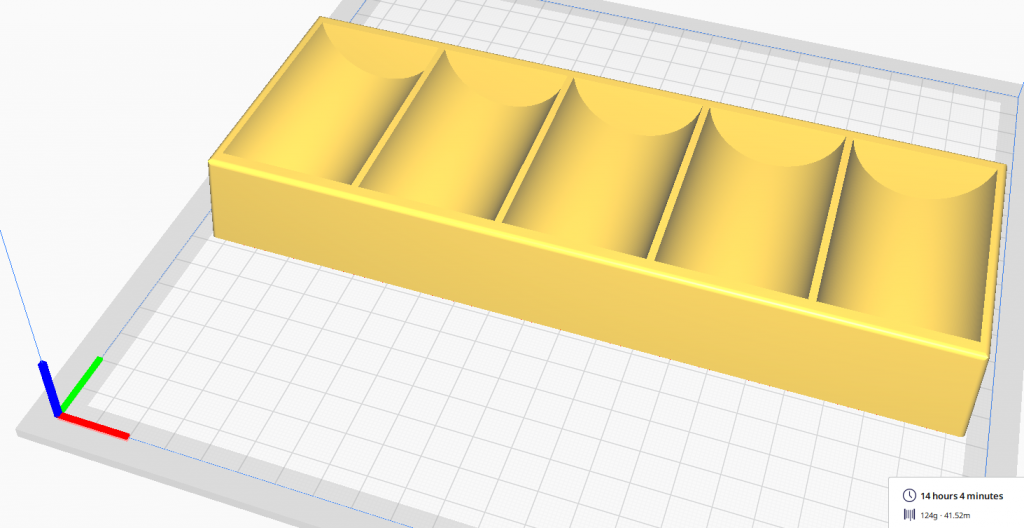

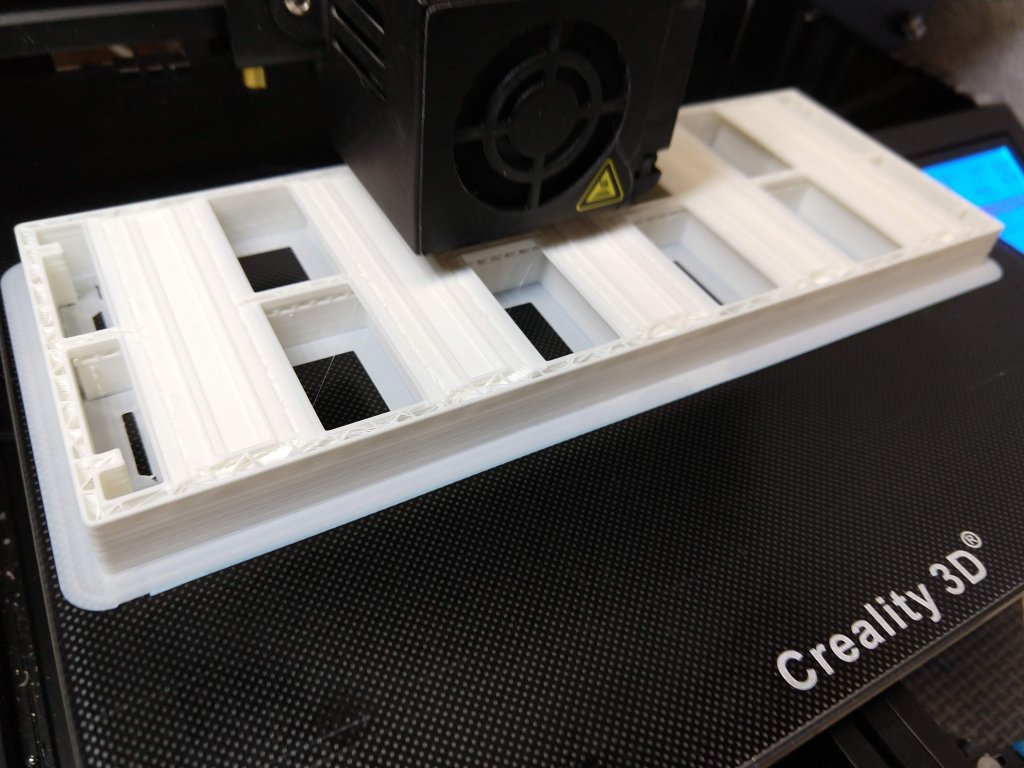

My latest 3D printer project is to make some racks. One of my goals is to print some custom-sized racks that will hold my 8V china clays that are too tall for normal racks. But to start with, I decided to model a copy of the Paulson rack as closely as I could. It was a good project to learn some new 3D modeling software, and it took me longer than I expected, but I'm happy with the result. I still need to do a few tweaks to the model, but I made a rough prototype print and the results are good. Here are some pictures. Keep in mind that this print is at very low quality to make it faster. Next I'm going to do a nicer print with a smaller layer height, so all the curves will be much smoother.

The chips fit nice and snug!

The chips fit nice and snug!