Colquhoun

4 of a Kind

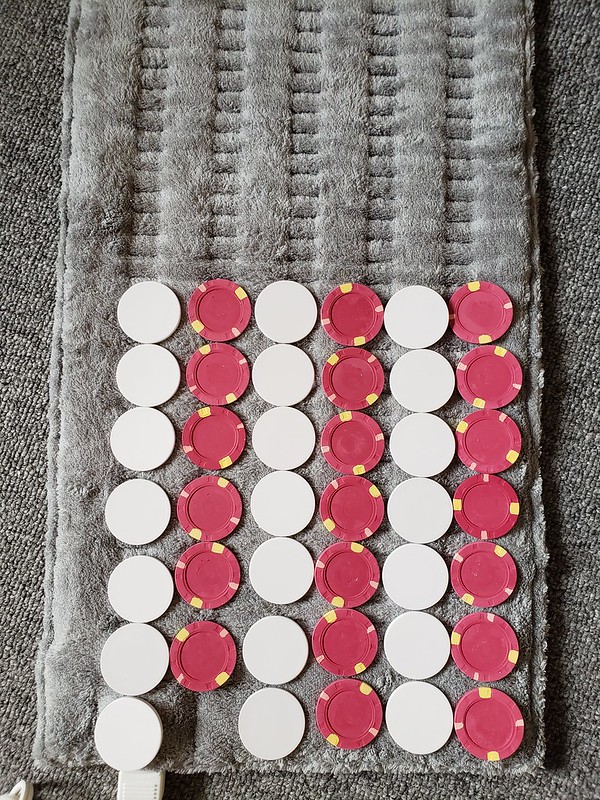

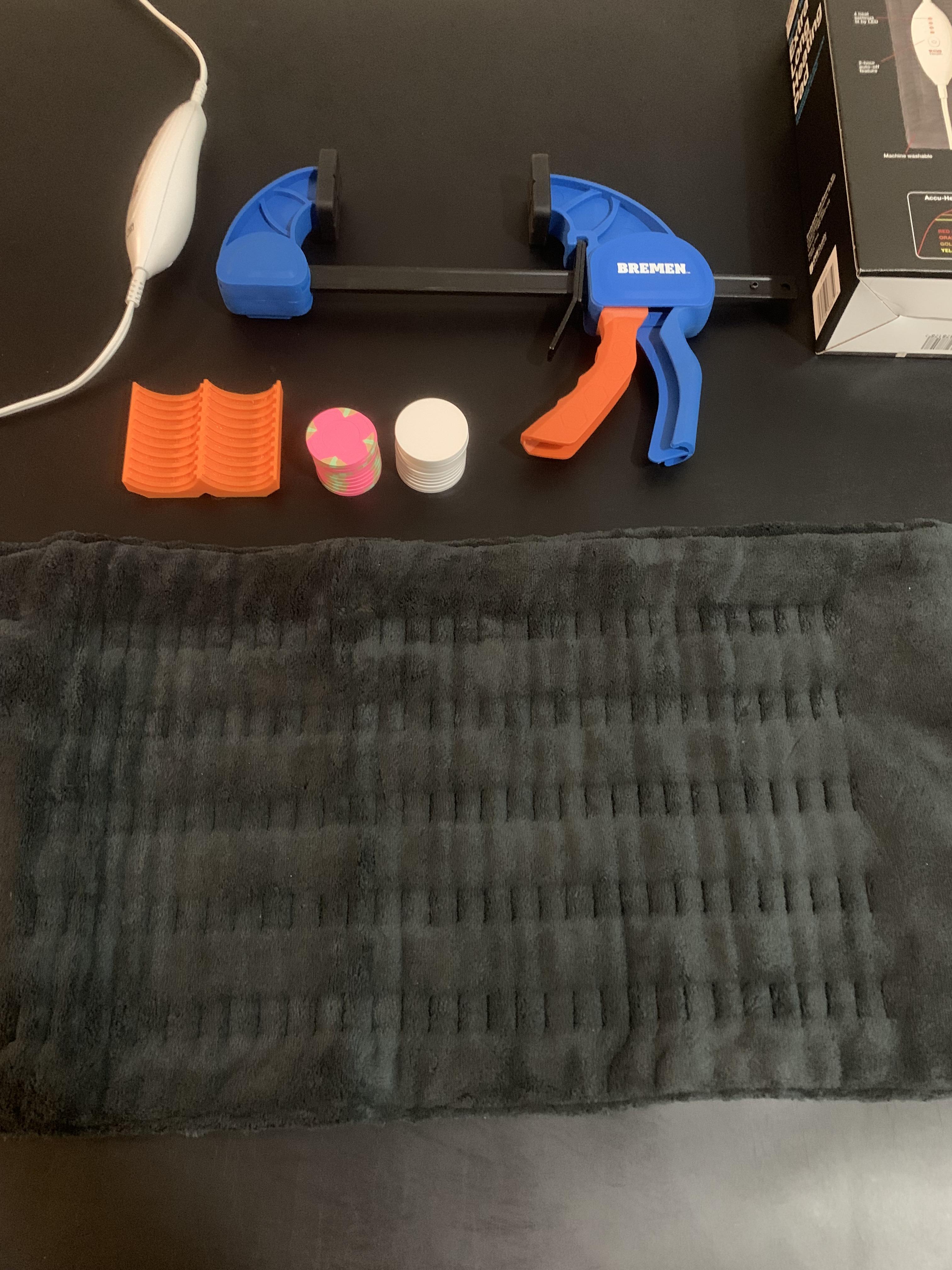

I use 39mm ceramics as spacers and drop a barrel of 10 chips and 10 spacers into a rack to line them up. Then clamp.They came out great!

I used 39 mm ceramics that I had laying around. I have blanks on order, but it looks like any random ceramics will do. Looking at the chips under high magnification, post flattening I see no evidence whatsoever that the 39mm blanks left any sort of ridge or flattened out any of the cross hatching so I am sticking to the 39 mm ceramics vs 43 which seems to me would be tough to line up without some sort of device like the 43mm ribbed chip flattening rack. That seems unnecessary to me... whatever works, right?