Definitely too much heat if there's color transfer. I guess the question I have was is there a way to provide enough heat to flatten without causing the color transfer. Looks like there absolutely is. Again, fantastic use of dealer buttons. Those fat hats look really good now!

-

PCF is an Amazon Associate and an eBay Partner. If you make a purchase through one of our links, we may earn a commission at no extra cost to you. Thank you for your support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flattening chips - question (1 Viewer)

- Thread starter Goldfish

- Start date

VMR911

Flush

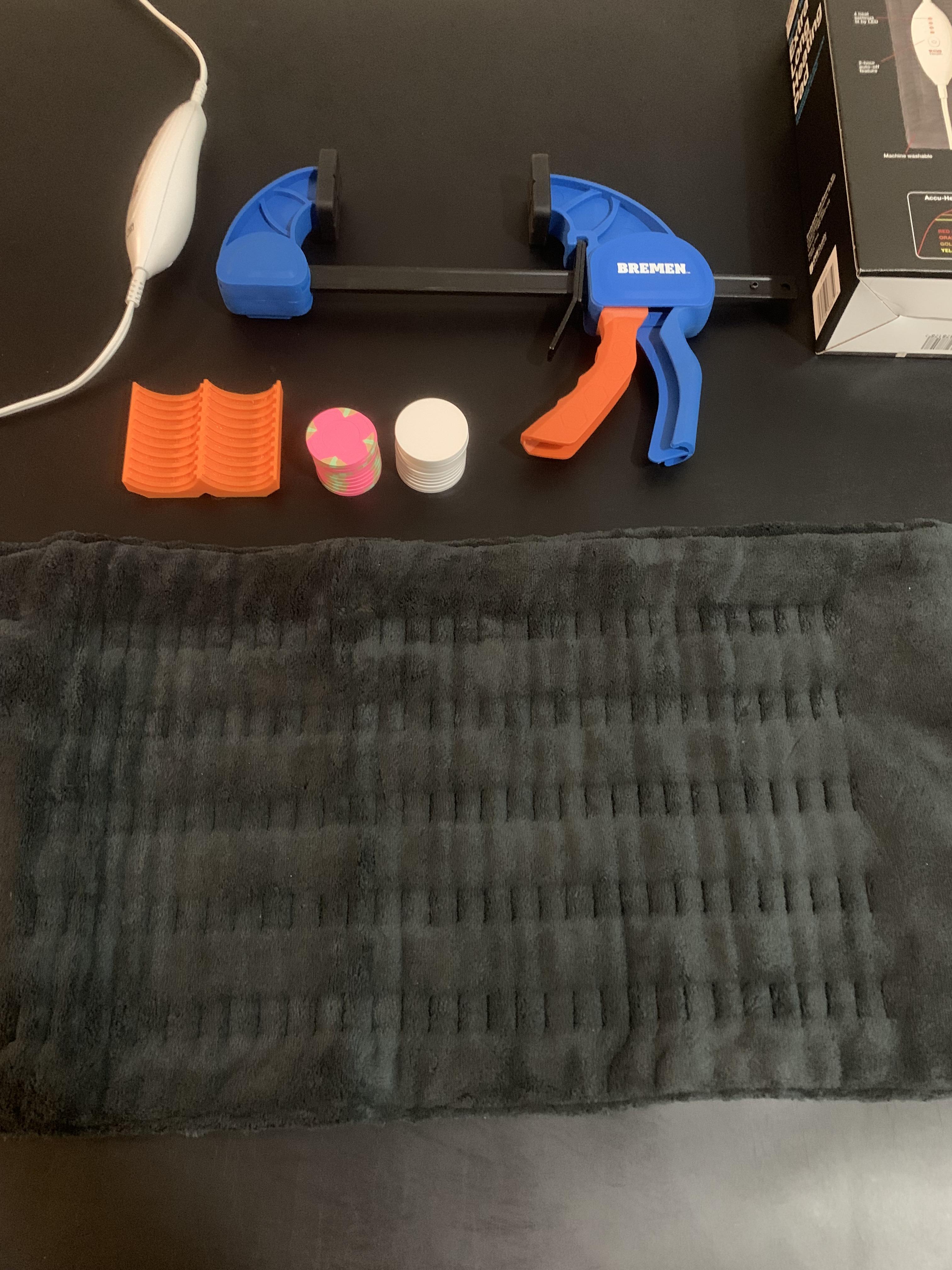

Where can I get these tools? The wooden one or this one.. are they inexpensive?So, I have been flattening chips at a rapid pace now..... the heating pad works GREAT!! I wrap the rack of chips in the heating pad for 60 mins at 160 degrees. The chips get to a temp of about 125-135 degrees. i let cool for at least 2 hours. The 39 mm come out nice and flat. I did a rack of 43 mm - which had a significant result but probably need another run to get completely flat. All said a big shout out to @BearMetal and @Colquhoun for the heating pad idea!! I have already ordered 2 more heating pads so I can run a barrel and a half at a time. Let’s gooooooo.

View attachment 616324

Nanook

Full House

Go back and look at my post in this thread #99 and you will see everything you need. Any quick clamps will do. HOME depot or Lowes & they are probably $5 or so. You really only need 1, but if you want to speed things up 4 of them helps a lot. Heating pad at CVS might have been $20 & the blank ceramic chips from gene at BR pro. Can't remember exactly but probably 25c ea or something. You can skip the blanks and just use any ceramic chips that you already have and save that. 1.5" dia PVC tubing I got a scrap piece for free at HD.Where can I get these tools? The wooden one or this one.. are they inexpensive?

Where can I get these tools? The wooden one or this one.. are they inexpensive?

I got the grip at Harbor Freight (free lifetime warranty), heating pad at CVS, and the blanks from BR Poker (they are an excellent and communicative vendor - just shoot them a PM if you need blanks). The ribbed flattening racks from @One Eyed Dollar work wonders and are a necessity for me.

If u go to CVS make sure to get the extra long series 700 (with the actual temp gauge). The regular size is not long enough to cover 10 chips and 11 ceramic spacers.Where can I get these tools? The wooden one or this one.. are they inexpensive?

Got clamps and the CVS extra long heating pad (per @Goldfish's rec) earlier this week, and 43mm ceramic blanks from @BR Pro Poker today--got 38 blanks (35¢ each), because that's how many I could get before shipping jumps from $6 to $10, so I can flatten 36 chips (18 chips + 19 blanks per clamp).

Don't have the ribbed racks, so I just hand placed the blanks and chips while holding the bar clamp vertically. The chips may not be dead even center on the blanks but I made sure none of them were too close to the edges. Set the heating pad to 160F and covered the clamps and chips. Will check and tighten in 20-30m, maybe flip the clamps over (even though I have the heating pad covering the top too).

Don't have the ribbed racks, so I just hand placed the blanks and chips while holding the bar clamp vertically. The chips may not be dead even center on the blanks but I made sure none of them were too close to the edges. Set the heating pad to 160F and covered the clamps and chips. Will check and tighten in 20-30m, maybe flip the clamps over (even though I have the heating pad covering the top too).

Nanook

Full House

I have had 160 F mark some chips so I always go with 140F and have never had an issue. Just FYI....

FYI, I switched to laying 10 chips and the spacers flat and heating them for 10-15 mins at 140 degrees - then immediately putting them in the clamps and let sit for 2 hours. Much faster.Got clamps and the CVS extra long heating pad (per @Goldfish's rec) earlier this week, and 43mm ceramic blanks from @BR Pro Poker today--got 38 blanks (35¢ each), because that's how many I could get before shipping jumps from $6 to $10, so I can flatten 36 chips (18 chips + 19 blanks per clamp).

Don't have the ribbed racks, so I just hand placed the blanks and chips while holding the bar clamp vertically. The chips may not be dead even center on the blanks but I made sure none of them were too close to the edges. Set the heating pad to 160F and covered the clamps and chips. Will check and tighten in 20-30m, maybe flip the clamps over (even though I have the heating pad covering the top too).

View attachment 885244

Last edited:

Thanks @Goldfish and @Nanook, The heating pad seemed to have turned off on their own after only 15-20m on 160F with "E4" on the control. Not sure if that meant an error. I had turned it back on and left them in at 160 F for only another 20m and then turned off the heating pad with the chips still inside. Been cooling for 2 hours so I'll be checking it shortly.

It turns off after 30 mins as a safety feature.Thanks @Goldfish and @Nanook, The heating pad seemed to have turned off on their own after only 15-20m on 160F with "E4" on the control. Not sure if that meant an error. I had turned it back on and left them in at 160 F for only another 20m and then turned off the heating pad with the chips still inside. Been cooling for 2 hours so I'll be checking it shortly.

Flattening the first 36 chips seemed to be a success. While the chips aren't perfectly flat, only 5 still have enough of a wobble that I'd put them through flattening again. The remaining 31 are quite acceptably flat to me.

I did compare a barrel of the flattened chips to a barren of the same chips that hadn't been flattened, and there was a very small but noticeable height difference, with the flattened barrel being every so slightly shorter, ~65.2mm vs ~66.1mm. I assume that's to be expected?

(Interestingly, I measured a few barrels that didn't need flattening and a few that did, and they both came out at ~66.1mm.)

I did compare a barrel of the flattened chips to a barren of the same chips that hadn't been flattened, and there was a very small but noticeable height difference, with the flattened barrel being every so slightly shorter, ~65.2mm vs ~66.1mm. I assume that's to be expected?

(Interestingly, I measured a few barrels that didn't need flattening and a few that did, and they both came out at ~66.1mm.)

There's a timer I can set it to 180m apparently. Anyway, it seemed to have turned off at least 10m before the first 30m mark, and the "E4" and the fact that I couldn't turn it on again without unplugging it and plugging it back in seemed to indicate some kind of error. It did turn back on again after and stayed on until I turned it off again. Will see with the next batch.It turns off after 30 mins as a safety feature.

Colquhoun

4 of a Kind

From the beginning, I’ve always layed the chips out flat and folded the heating pad over them. I place the spacers on top, just to get them warm as well.

This method only requires 10 minutes of heat time.

Stack them up, and clamp.

This method only requires 10 minutes of heat time.

Stack them up, and clamp.

I feel like because I'm using 43mm spacers without the ribbed rack, it takes me a little bit of time to balance and stack the alternating spacers and chips vertically on the bar clamp "platform", taking time to center the chips between the blanks, that I'd probably lose a decent amount of heat. I'm okay with stacking and clamping them first, then wrapping the heating pad around and letting them warm. Second batch just finished heating at 140F and I'll let them cool overnight.From the beginning, I’ve always layed the chips out flat and folded the heating pad over them. I place the spacers on top, just to get them warm as well.

This method only requires 10 minutes of heat time.

Stack them up, and clamp.

Nanook

Full House

If you only have a rack to do your method is fine, but it is going to take a lot of extra time. If you have a lot to do, you really need either the spacer thing or something like I use with the 1.5" PVC tube cut in two. Lining everything up takes me 2 seconds and it works perfectly every time. See my post #99 in this thread: https://www.pokerchipforum.com/threads/flattening-chips-question.67486/page-4#post-1586920I feel like because I'm using 43mm spacers without the ribbed rack, it takes me a little bit of time to balance and stack the alternating spacers and chips vertically on the bar clamp "platform", taking time to center the chips between the blanks, that I'd probably lose a decent amount of heat. I'm okay with stacking and clamping them first, then wrapping the heating pad around and letting them warm. Second batch just finished heating at 140F and I'll let them cool overnight.

Thanks for the advice! Right now I only have 1.5 racks of chips hat really need flattening. Might go though the rest of my chips to see if there's more. I was able to get the heating pad, 43mm blanks, and clamps within a few days. The 3D printed ribbed rack would have taken longer so I just tried the manual, balancing act because I didn't want to want. Plan on getting those racks to make it way easier in the future!If you only have a rack to do your method is fine, but it is going to take a lot of extra time. If you have a lot to do, you really need either the spacer thing or something like I use with the 1.5" PVC tube cut in two. Lining everything up takes me 2 seconds and it works perfectly every time. See my post #99 in this thread: https://www.pokerchipforum.com/threads/flattening-chips-question.67486/page-4#post-1586920

Actually, I went through some of my chips and it looks like I'll have more to flatten, so will try to get the ribbed racks sooner rather than later!

Last edited:

Nanook

Full House

If directed at me, you are welcomeThanks for the advice!

I have found that almost all used chips have some warped chips in there. You don't realize how nice it is to have flat chips until you start messing around with flattening them.Actually, I went through some of my chips and it looks like I'll have more to flatten, so will try to get the ribbed racks sooner rather than later!

Yes directed at you (and others), thanks!If directed at me, you are welcome

I have found that almost all used chips have some warped chips in there. You don't realize how nice it is to have flat chips until you start messing around with flattening them.

louBdub

4 of a Kind

Look what you’ve started……..

Nanook

Full House

looks like you are on the right track!.Look what you’ve started…….. View attachment 889573

Don't go higher than 140°F thinking that hotter is better. It is not & can damage the chips, but other than that you really can't go wrong. Chips that are flat and stack well are so much nicer than warped wobbly stacks!

louBdub

4 of a Kind

This pad says max setting is 140, so that’s where it’s at. Timer is set and I’ll be rotating the clamps and stackin stacks throughout the daylooks like you are on the right track!.

Don't go higher than 140°F thinking that hotter is better. It is not & can damage the chips, but other than that you really can't go wrong. Chips that are flat and stack well are so much nicer than warped wobbly stacks!

Thx for the tip!!!

Nanook

Full House

looking closer at your pic, do you have ceramic blanks in between each chip. I don't see them, but maybe they are there. I know others have had good luck with the thingy ma jiggy that helps line everything up. I am sure that works great too, but for free I asked for, and got a scrap of 1.5" dia PVC pipe at HD and then cut it in half the long way. Make it about 8' long and it works like a champ for free. It should look something like this:This pad says max setting is 140, so that’s where it’s at. Timer is set and I’ll be rotating the clamps and stackin stacks throughout the day

Thx for the tip!!!

louBdub

4 of a Kind

I do, it’s just blue CPCs mixed with blue ceramics haha.looking closer at your pic, do you have ceramic blanks in between each chip. I don't see them, but maybe they are there. I know others have had good luck with the thingy ma jiggy that helps line everything up. I am sure that works great too, but for free I asked for, and got a scrap of 1.5" dia PVC pipe at HD and then cut it in half the long way. Make it about 8' long and it works like a champ for free. It should look something like this:

Nanook

Full House

perfectI do, it’s just blue CPCs mixed with blue ceramics haha.

dmoney

Full House

Very small test run before I get some more ceramic blanks and a flattening rack. Success! Not perfect but much improved (4th chip from the right).

Attachments

dmoney

Full House

Got a little overzealous and also realized that my clamp is not straight. Uneven pressure broke the ceramic chip I was using as a spacer and warped the starburst chip it was touching, but thankfully not beyond repair.

Good news, though: the other chips are fine and now stack like bricks.

Stopping here until I get the proper supplies - better clamp, 43mm ceramic spacers between all chips, flattening rack. Lesson learned.

Good news, though: the other chips are fine and now stack like bricks.

Stopping here until I get the proper supplies - better clamp, 43mm ceramic spacers between all chips, flattening rack. Lesson learned.

Attachments

Colquhoun

4 of a Kind

Whoa!Got a little overzealous and also realized that my clamp is not straight. Uneven pressure broke the ceramic chip I was using as a spacer and warped the starburst chip it was touching, but thankfully not beyond repair.

Good news, though: the other chips are fine and now stack like bricks.

Stopping here until I get the proper supplies - better clamp, 43mm ceramic spacers between all chips, flattening rack. Lesson learned.

WAY too much pressure. I've found the only pressure required is slightly more than is needed to just hold them together.

To give you an idea, hold the stack up to a bright light and see how much light is visible between the chips. Heat the chips then arrange in the clamp, and hold to the light while tightening...you'll see it takes so little pressure for the chips to come together.

That's all the pressure needed.

With my bar clamps, I give the tightening handles a firm handshake. So far so good, but I find some chips just won't flatten even after multiple attempts, with more pressure, with higher temps (150-160), etc. Have you found that some chips will never flatten (and I'm not expecting perfectly flat, but some are still quite wobbly after multiple flattening sessions)?Whoa!

WAY too much pressure. I've found the only pressure required is slightly more than is needed to just hold them together.

To give you an idea, hold the stack up to a bright light and see how much light is visible between the chips. Heat the chips then arrange in the clamp, and hold to the light while tightening...you'll see it takes so little pressure for the chips to come together.

That's all the pressure needed.

Colquhoun

4 of a Kind

How long are you allowing them to cool?With my bar clamps, I give the tightening handles a firm handshake. So far so good, but I find some chips just won't flatten even after multiple attempts, with more pressure, with higher temps (150-160), etc. Have you found that some chips will never flatten (and I'm not expecting perfectly flat, but some are still quite wobbly after multiple flattening sessions)?

I’ve been allowing myself to “cool” for 36 yearsHow long are you allowing them to cool?

2+ hoursHow long are you allowing them to cool?

Similar threads

- Replies

- 3

- Views

- 202