-

PCF is an Amazon Associate and an eBay Partner. If you make a purchase through one of our links, we may earn a commission at no extra cost to you. Thank you for your support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EXTRA!!! TR King style TRI-MOON edge spots now available. (2 Viewers)

- Thread starter David Spragg

- Start date

also, some of the Deadwoods are tri-moon, y'all might be thinking of those

andy699669

3 of a Kind

A great addition to the CPC family! Maybe new colours and edgespots on the works? And which one is wider, Rank 1 312 or Rank 2 3MOON/3HC?

I'm committed. And there are Oompa Loompas designing this set as we speak.

Maybe start an official stock Rounders set interest/deposit thread.

Go ahead and start it.

Hopefully quickly

Lots of “beer muscles” in these types of posts as you know, David. That said, this seems like another quantum leap by CPC. *Applause*

Steamtrain

3 of a Kind

Damn it!

Quicksilver-75

4 of a Kind

@David Spragg

Sooooo.....is it too late for me to make a small change?

Sooooo.....is it too late for me to make a small change?

Amish Rabbi

Straight

great looking mold and edge spots!

I’d need commitments/deposits to do it. A stock set on a mold that may only run every 9 months means you have to make and hold $15k worth (at cost) of inventory. Plus they will be more expensive than the scrolls.

Maybe someone here could start it off.

I'm committed. And there are Oompa Loompas designing this set as we speak.

Maybe start an official stock Rounders set interest/deposit thread.

I am in for a set...1100 chips

slisk250

Straight Flush

Spots have been added to the chip tool and will be added to the website shortly.

View attachment 230306View attachment 230307

Nice! Can you make a time machine and set it back 3 years?

Your Mike’s are still spectacular!Nice! Can you make a time machine and set it back 3 years?

Nex

Flush

May I ask what model of 3D printer you got, and what type of material you're printing the punches with? PETG? ABS? I've heard the stuff most people print with, PLA, was very brittle.

I ordered a Prusa i3 MK3 a couple days ago

I ordered a Prusa i3 MK3 a couple days ago

May I ask what model of 3D printer you got, and what type of material you're printing the punches with? PETG? ABS? I've heard the stuff most people print with, PLA, was very brittle.

I ordered a Prusa i3 MK3 a couple days ago

Flashforge Creator Pro. Spec looks about the same as yours. Using PLA although I tried others. No problem with it being brittle so far. Remember the punch is only pressing out pieces of soft clay, and the surfaces do not come into contact with anything. When you get the printer you will see there are all sorts of different settings for speed/density/layer thickness which affect strength.

5aces

Full House

Is there any "House of Cards" custom set out there? I like the idea (and the series for sure).

Next to that I thought about to change "The Mapes Hotel/Casino" to "The Babes Hotel/Casino".

Next to that I thought about to change "The Mapes Hotel/Casino" to "The Babes Hotel/Casino".

Last edited:

Every wall of resistance put up is slowly being chipped away...

Nex

Flush

...announcement a couple of months down the line:

"Supply your custom punch design and we'll make chips with them! *

* no guarantees on product stability"

Well, probably not

But when I first read that you were planning to try 3D printer prototyping for punches, I got the idea to try make a set of cookie cutters that would work the same way. Multiple punches for multiple edge spot designs, and some sort of stamp punch to apply a "mold" design on one side.

I'm not sure if answering this would touch trade secrets or not... Do you use separate punches for punching the holes in the chip bodies, and for punching the actual spots from different-colored clay? Also - if the soft clay was about as sticky as butter cookie dough - do the punches have some sort of mechanism to push out parts that get stuck inside the punch?

Since the traditional metal punches are so expensive, I assume you'd use the same punch for both applications - which seems to be very inefficient for me to punch just the spots as there would be so much waste material left over. I somehow doubt it'd be possible to just gather all the leftover scraps from a color and roll a fresh plate from that?

If the 3D printed punches are stable enough to last for a reasonable amount of time, it might be worth it to make separate punches for the spots that would punch many at a time and arranged in a way that produces as few leftover scraps as possible. Might reduce production costs and workload. I'm definitely going to try this when I draw the designs for the cookie cutters. Still going through some AutoCAD video tutorials

"Supply your custom punch design and we'll make chips with them! *

* no guarantees on product stability"

Well, probably not

But when I first read that you were planning to try 3D printer prototyping for punches, I got the idea to try make a set of cookie cutters that would work the same way. Multiple punches for multiple edge spot designs, and some sort of stamp punch to apply a "mold" design on one side.

I'm not sure if answering this would touch trade secrets or not... Do you use separate punches for punching the holes in the chip bodies, and for punching the actual spots from different-colored clay? Also - if the soft clay was about as sticky as butter cookie dough - do the punches have some sort of mechanism to push out parts that get stuck inside the punch?

Since the traditional metal punches are so expensive, I assume you'd use the same punch for both applications - which seems to be very inefficient for me to punch just the spots as there would be so much waste material left over. I somehow doubt it'd be possible to just gather all the leftover scraps from a color and roll a fresh plate from that?

If the 3D printed punches are stable enough to last for a reasonable amount of time, it might be worth it to make separate punches for the spots that would punch many at a time and arranged in a way that produces as few leftover scraps as possible. Might reduce production costs and workload. I'm definitely going to try this when I draw the designs for the cookie cutters. Still going through some AutoCAD video tutorials

Last edited:

Quicksilver-75

4 of a Kind

And my $100 just got a huge makeover!

Orgasmic!

Orgasmic!

detroitdad

Royal Flush

I'll buy an extra 100 chip off of you if you have any extras to spare. That is fricken sexy.

andy699669

3 of a Kind

Is it me or '3TRIM' is a little redundant? (The name would be 3 TriMoon, kinda similar to Commodore CDTV (Commodore Commodore Dynamic Total Vision), or DC Comics (Detective Comics Comics)). Maybe rename it to either 3Moon/3HC?

Last edited:

Nex

Flush

3HC would probably be the least misleading, as Paulson offers both 3HC and 3Moon.

And it appears to me like the Paulson 3HC has exactly the same shape as the TRK Tri-Moon.

And it appears to me like the Paulson 3HC has exactly the same shape as the TRK Tri-Moon.

Poker Zombie

Royal Flush

You could call it "Punch 79-X", for all I care... I just want some!

I need one more thing - canary yellow!

Awesome! As soon as they good a good yellow, I'll be placing my order!

What they said...

Mr Tree

Straight Flush

Wow. Big thumbs up.

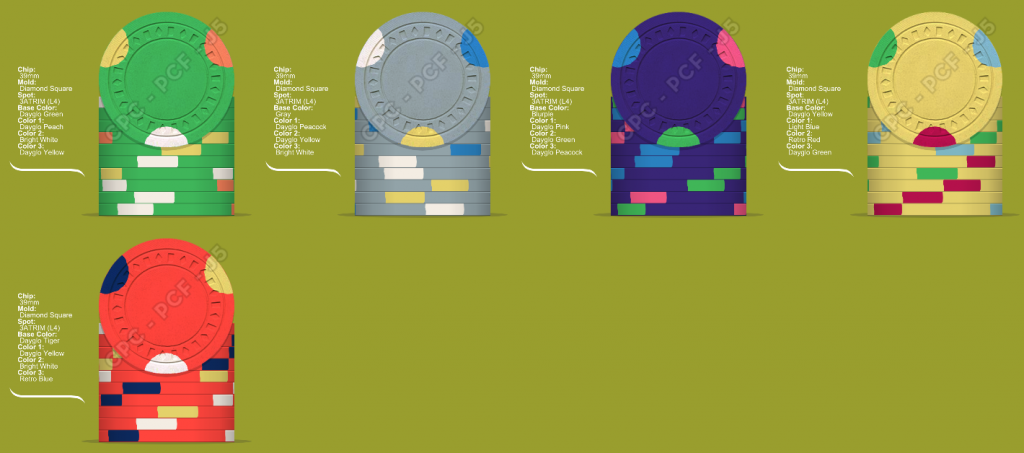

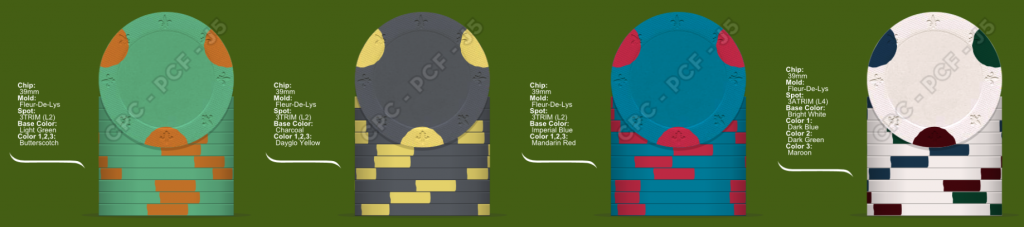

Trying all different color combos, would love to see lots more.

Quicksilver-75

4 of a Kind

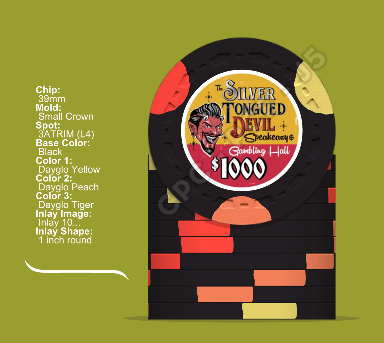

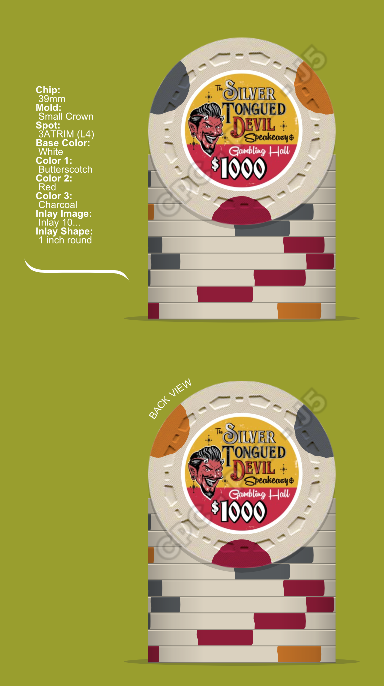

After careful consideration of cost and color distribution amongst the set Ive asked David to change my t500. It now looks like this. Besides, I really like my Hundo as is. (The inlay pictured is wrong and was the only one I had on my phone.)

Maybe 25, 100, 500, 2000... 400 chip hotstamp set for 10 seats.

I know... 2000's aren't common, but why not.

Maybe elephant mould?

If the small crown mould is ever hotstamp-ready I'd definitely go with those.

EDIT:

Dah! Though I knew small crown was out, I just saw:

"Hot Stamping is available on the following seven 39mm molds.

A-CREST, CIRCLE SQUARE, HORSEHEAD, JOCKEY, SCROLL, B-DIAMOND, DIECARD.

It is not available on molds not listed above including SMALL CROWN"

Ugh. I want something other than "A" for my next CPC. Maybe Jockey for these.

I know... 2000's aren't common, but why not.

Maybe elephant mould?

If the small crown mould is ever hotstamp-ready I'd definitely go with those.

EDIT:

Dah! Though I knew small crown was out, I just saw:

"Hot Stamping is available on the following seven 39mm molds.

A-CREST, CIRCLE SQUARE, HORSEHEAD, JOCKEY, SCROLL, B-DIAMOND, DIECARD.

It is not available on molds not listed above including SMALL CROWN"

Ugh. I want something other than "A" for my next CPC. Maybe Jockey for these.

Last edited:

...announcement a couple of months down the line:

"Supply your custom punch design and we'll make chips with them! *

* no guarantees on product stability"

Well, probably not

But when I first read that you were planning to try 3D printer prototyping for punches, I got the idea to try make a set of cookie cutters that would work the same way. Multiple punches for multiple edge spot designs, and some sort of stamp punch to apply a "mold" design on one side.

I'm not sure if answering this would touch trade secrets or not... Do you use separate punches for punching the holes in the chip bodies, and for punching the actual spots from different-colored clay? Also - if the soft clay was about as sticky as butter cookie dough - do the punches have some sort of mechanism to push out parts that get stuck inside the punch?

Since the traditional metal punches are so expensive, I assume you'd use the same punch for both applications - which seems to be very inefficient for me to punch just the spots as there would be so much waste material left over. I somehow doubt it'd be possible to just gather all the leftover scraps from a color and roll a fresh plate from that?

If the 3D printed punches are stable enough to last for a reasonable amount of time, it might be worth it to make separate punches for the spots that would punch many at a time and arranged in a way that produces as few leftover scraps as possible. Might reduce production costs and workload. I'm definitely going to try this when I draw the designs for the cookie cutters. Still going through some AutoCAD video tutorials

Obviously I can't go into much detail but your vision of the process is a long way from what actually happens

That’s a beautiful chip!After careful consideration of cost and color distribution amongst the set Ive asked David to change my t500. It now looks like this. Besides, I really like my Hundo as is. (The inlay pictured is wrong and was the only one I had on my phone.)

View attachment 230543

Nex

Flush

I've simply never seen an actual chip punch before, so I started from cookie cutters and made some more or less wild assumptions

A while ago I believe you posted about some retired punch that you donated to a museum. Are there any photos of it? (Since it's on display in some museum, I guess trade secrets are no longer an issue for this one specific punch)

A while ago I believe you posted about some retired punch that you donated to a museum. Are there any photos of it? (Since it's on display in some museum, I guess trade secrets are no longer an issue for this one specific punch)

Similar threads

- Replies

- 2

- Views

- 298

- Replies

- 12

- Views

- 1K

Services

IMPORTANT CPC BULLETIN

- Replies

- 200

- Views

- 24K

- Sticky

Collecting (ordering closed)

PCF Full-Size Toppers, PCF Mini Toppers, and PCF OFCP Toppers

- Replies

- 106

- Views

- 5K