You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

eBay pickup. Burt hourglass mold. (2 Viewers)

- Thread starter BamaT8ter

- Start date

Seeking Alpha Social Club

4 of a Kind

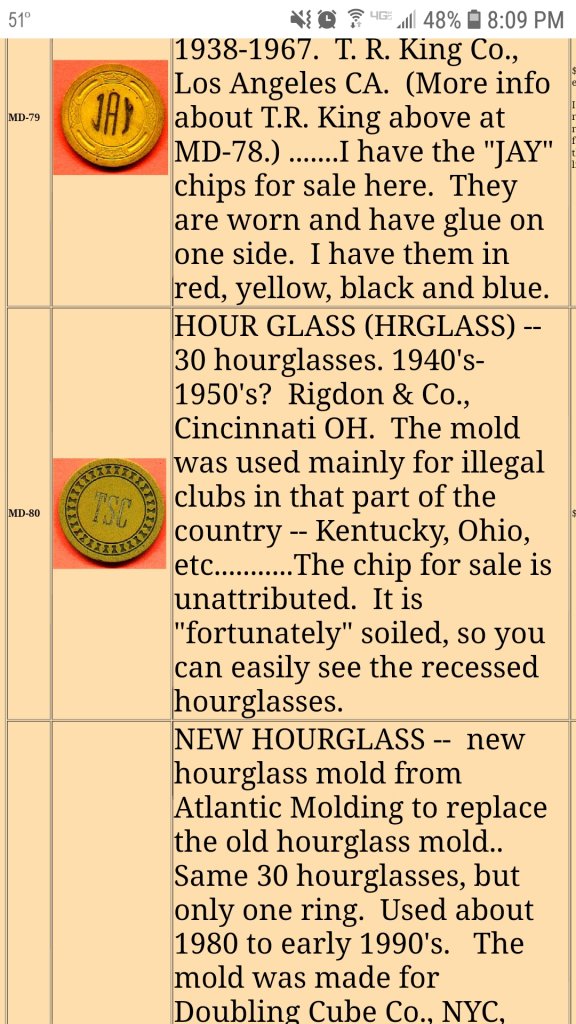

Rigdon & Co. Maybe? I have an hour glass set, and I always thought they were Rigdon & Co's

BamaT8ter

Full House

They may be. Reading some things on here, I was under the impression that Burt was who made them for Rigdon, but I certainly could be wrong. That’s a beautiful set. I haven’t decided what to do with these yet. Heck, I don’t even have them in my hands yet. But I couldn’t pass them up.

Seeking Alpha Social Club

4 of a Kind

You might be right. I don't know enough about Rigdon's history.

Thanks! They feel fantastic in play, but be careful, they break pretty easy compared to Paulsons. I dropped one and it cracked pretty easy.

Let me know if you ever decide to get rid of them

Thanks! They feel fantastic in play, but be careful, they break pretty easy compared to Paulsons. I dropped one and it cracked pretty easy.

Let me know if you ever decide to get rid of them

99% of old clays that aren't Paulson or TRK, are Burt Co. There were only ever seven manufacturers that made clay chips, but you can boil that list down to 4 if you want to.Rigdon & Co. Maybe? I have an hour glass set, and I always thought they were Rigdon & Co's

View attachment 575290View attachment 575291

Burt Co/ASM/CPC

Paulson

TRK

Matsui

BCC

USPC

Hispania

You can condense that list to just Burt Co, Paulson, Matsui, and TRK; as BCC just used old Paulson equipment and methods, Hispania bought all of their equipment from Burt Co, and USPC sold all their equipment to Burt Co.

Nice pickup. I like the old hourglass mold, it has a smaller recess and a nicer feel compared to the current hourglass mold, which is in my bottom three molds for CPC.

Seeking Alpha Social Club

4 of a Kind

Great info!! Thanks!!99% of old clays that aren't Paulson or TRK, are Burt Co. There were only ever seven manufacturers that made clay chips, but you can boil that list down to 4 if you want to.

Burt Co/ASM/CPC

Paulson

TRK

Matsui

BCC

USPC

Hispania

You can condense that list to just Burt Co, Paulson, Matsui, and TRK; as BCC just used old Paulson equipment and methods, Hispania bought all of their equipment from Burt Co, and USPC sold all their equipment to Burt Co.

Nice pickup. I like the old hourglass mold, it has a smaller recess and a nicer feel compared to the current hourglass mold, which is in my bottom three molds for CPC.

CrazyEddie

Full House

Got any info about, or examples of, Matsui clays? I recall @BGinGA saying they weren't very successful..Matsui

There’s this thread:Got any info about, or examples of, Matsui clays? I recall @BGinGA saying they weren't very successful..

https://www.pokerchipforum.com/threads/clay-matsui-chips.9871/

And I think there was a 200-chip set of Matsui clays somebody on here has, so if you find them you can ask some questions. I’m not 100% sure that they were really compression-molded, but I have no evidence that they were injection-molded, and have yet to feel any for myself, so I can’t be sure either way.

Really cool find thanks for sharing!

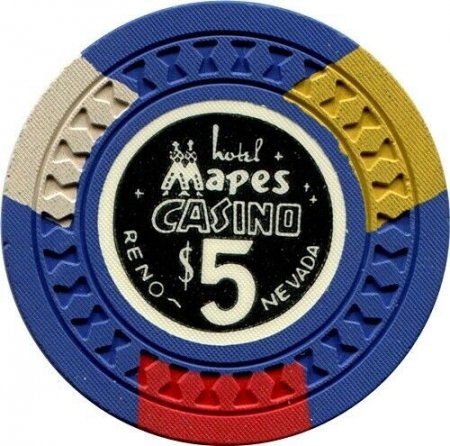

The old Hourglass with the outer ring was much better than the new Hourglass mold without it. There were some casino chips made with this old Hourglass mold most notably the Mapes.

CrazyEddie

Full House

Thanks for that pointer!There’s this thread:

https://www.pokerchipforum.com/threads/clay-matsui-chips.9871/

And I think there was a 200-chip set of Matsui clays somebody on here has, so if you find them you can ask some questions. I’m not 100% sure that they were really compression-molded, but I have no evidence that they were injection-molded, and have yet to feel any for myself, so I can’t be sure either way.

I think we have to remove Matsui from the list of manufacturers of clay chips. Seems very clear to me that they're injection molded: they only offer one spot configuration and they only offer labels, not inlays. These are hallmarks of injection molding, and it's compression molding which gives the chips we call "clay" their fundamental character.

Matsui might call them clay, but outside of this forum "clay" is a completely meaningless term, used by everyone to describe every kind of chip.

That may be true, but it’s surprisingly difficult to make inlays in clay chips. Matsui would have had to invest hundreds of thousands of dollars to get more than one edge spot and to have real inlays. I’ll email Roxana from Matsui and see if she has any more information, but I’d say it has the possibility to be a manufacturer. One of the main reasons I didn’t immediately dismiss them as injection-molded was because of the photos showing a bunch of clay chips that were baked in the oven, which seemed to show similarities between Matsui chips and some well-known compression molded clays.Thanks for that pointer!

I think we have to remove Matsui from the list of manufacturers of clay chips. Seems very clear to me that they're injection molded: they only offer one spot configuration and they only offer labels, not inlays. These are hallmarks of injection molding, and it's compression molding which gives the chips we call "clay" their fundamental character.

Matsui might call them clay, but outside of this forum "clay" is a completely meaningless term, used by everyone to describe every kind of chip.

CrazyEddie

Full House

I saw those photos. Interesting, but I'm not sure what they demonstrate.

One way to confirm that the chips were injection molded would be to take several chips and closely compare their edge spots. Edge spots made by compression molding will have minor variations from chip to chip, so that every chip is unique. Edge spots made by injection molding will be the same from chip to chip with high precision, so that every chip is identical. You can see this difference by looking very closely at some Paulsons and then some china clays.

Of course, then we'd have to have someone with a sample of Matsui clays in their hands to do the comparison...

One way to confirm that the chips were injection molded would be to take several chips and closely compare their edge spots. Edge spots made by compression molding will have minor variations from chip to chip, so that every chip is unique. Edge spots made by injection molding will be the same from chip to chip with high precision, so that every chip is identical. You can see this difference by looking very closely at some Paulsons and then some china clays.

Of course, then we'd have to have someone with a sample of Matsui clays in their hands to do the comparison...

Based on results of the destructive tests (and Matsui claims), I'm sticking with M molds being clay unless proven otherwise.

Plastics don't react to high temperature heat like clays.

Our chipping forefathers who did own and handle these chips were very unforgiving about plastics being advertised as clays, and would have been singing from the rafters had any indication or signs of injection-molding been present.

Plastics don't react to high temperature heat like clays.

Our chipping forefathers who did own and handle these chips were very unforgiving about plastics being advertised as clays, and would have been singing from the rafters had any indication or signs of injection-molding been present.

Last edited:

CrazyEddie

Full House

So... made from thermosetting rather than thermoplastic materials, and compression molded... but for some reason, unable to take an inlay during the molding process, and unable to cut different insert patterns into the blanks.

Seems plausible, but it mostly just makes me wish I had more details about how Matsui made these.

Also it makes me want to get my hands on some!

Seems plausible, but it mostly just makes me wish I had more details about how Matsui made these.

Also it makes me want to get my hands on some!

To take an inlay the chip needs to be punched with the shape/size of it. That’s why CPC can’t just print whatever size inlay you want and stick it on the chip before pressing. Along with that, there is a special process that involves some sort of varnish, I believe, which you would only know about if you worked for a compression clay company before.So... made from thermosetting rather than thermoplastic materials, and compression molded... but for some reason, unable to take an inlay during the molding process, and unable to cut different insert patterns into the blanks.

Seems plausible, but it mostly just makes me wish I had more details about how Matsui made these.

Also it makes me want to get my hands on some!

Edit: I’m not 100% sure if other companies like TRK and Paulson actually required inlay punches but again, as with many other parts of compression molding, very few people have the knowledge to back that up. I do know CPC requires them, though.

Imo....

For a company that already has laminated adhesive label production capacity, it makes perfect sense to offer molded chips with a recess/label (plus hot stamps) vs trying to reinvent the wheel and attempt compression-molded inlays.

Before they closed doors, PGI was also investigating a similar approach.

For a company that already has laminated adhesive label production capacity, it makes perfect sense to offer molded chips with a recess/label (plus hot stamps) vs trying to reinvent the wheel and attempt compression-molded inlays.

Before they closed doors, PGI was also investigating a similar approach.

And....

Edge spot (inserts) capability is purely a function of having the applicable dies needed to cut the different shapes into the chip slugs (and the replacement inserts from raw material)..... plus how well (or poorly) they stay together once assembled until pressed.

The investment required for low temp/low pressure compression manufacturing is much smaller than a high temp/high pressure operation.it’s surprisingly difficult to make inlays in clay chips. Matsui would have had to invest hundreds of thousands of dollars to get more than one edge spot and to have real inlays.

Edge spot (inserts) capability is purely a function of having the applicable dies needed to cut the different shapes into the chip slugs (and the replacement inserts from raw material)..... plus how well (or poorly) they stay together once assembled until pressed.

CrazyEddie

Full House

Agreed. But then, for the same reason, it also seems odd that they would invest in compression-molded chips at all! They've got injection-mold equipment and infrastructure - quite sophisticated, given the quality of IM chips they produce - so all they'd need to invest in further is some new molds that replicate the "clay chip" appearance of debossed edge molds and colored inserts, and then just use the new IM molds on their existing IM presses.For a company that already has laminated adhesive label production capacity, it makes perfect sense to offer molded chips with a recess/label (plus hot stamps) vs trying to reinvent the wheel and attempt compression-molded inlays.

Maybe it's a matter of materials. I read the old chiptalk review (via the wayback machine) and the reviewer was impressed with the feel, calling them "second only to Paulson", so they must be made out of a very different material from their bread-and-butter casino plastics line. Maybe that new material called for an entirely new press. Maybe they were consciously trying to duplicate the feel of typical clays, and so decided to duplicate the production method as well.

mysteries abound

CrazyEddie

Full House

That is super interesting! I hadn't known that.To take an inlay the chip needs to be punched with the shape/size of it.

Some companies have been able to add inlays without needing to pre-punch the inlay shape, I suspect. The various vintage Paranoid chips have die-cut inlays in weird shapes; I suspect they didn't have matching punches to pre-punch a weird-shaped indentation in the surface. Likewise with the intricate die-cut metal inlays on some Burt Co chips, like the ones in this post.Edit: I’m not 100% sure if other companies like TRK and Paulson actually required inlay punches but again, as with many other parts of compression molding, very few people have the knowledge to back that up. I do know CPC requires them, though.

But! I wasn't there, I don't know, I could be wrong! Maybe any time they made a die to cut fancy shapes, they used that same die to fabricate punches so that the die-cut inlays would lie smoothly within the chip surface before pressing. I'd been assuming that all that was necessary was to plop the inlay underneath and on top of the blank semi-cured chip and let the pressure of the mold do the rest. Maybe that was a rash assumption.

CrazyEddie

Full House

I'll reserve my opinion until I can hold some in my very own hands. Any volunteers?I'll assume after reading that 2005 chip review that you now agree that the Matsui M mold chips are/were indeed compression-molded clays.

I think the reason the intricate metal and paranoid designs didn't need a punch is that all of the chips that had those were solid. That means that having a large amount of clay displacement would not make the edge spots get wildly messed up. Inlays, on the other hand, are frequently put on chips with edge spots so they can't afford to have that much inlay displacement, or else the chips would all look like they were made by Dr. Ott.Some companies have been able to add inlays without needing to pre-punch the inlay shape, I suspect. The various vintage Paranoid chips have die-cut inlays in weird shapes; I suspect they didn't have matching punches to pre-punch a weird-shaped indentation in the surface. Likewise with the intricate die-cut metal inlays on some Burt Co chips, like the ones in this post.

But! I wasn't there, I don't know, I could be wrong! Maybe any time they made a die to cut fancy shapes, they used that same die to fabricate punches so that the die-cut inlays would lie smoothly within the chip surface before pressing. I'd been assuming that all that was necessary was to plop the inlay underneath and on top of the blank semi-cured chip and let the pressure of the mold do the rest. Maybe that was a rash assumption.

Edit: Immediately after writing this I checked the link again and noticed one of the chips had edge spots. I think this still applies to paranoids, but I don't know about the intricate metal designs.

Seeking Alpha Social Club

4 of a Kind

Matsui actually has a video on their website that explains the process (at least in part).That may be true, but it’s surprisingly difficult to make inlays in clay chips. Matsui would have had to invest hundreds of thousands of dollars to get more than one edge spot and to have real inlays. I’ll email Roxana from Matsui and see if she has any more information, but I’d say it has the possibility to be a manufacturer. One of the main reasons I didn’t immediately dismiss them as injection-molded was because of the photos showing a bunch of clay chips that were baked in the oven, which seemed to show similarities between Matsui chips and some well-known compression molded clays.

Matsui Clays

The link was a different color, it made no sense, but I still clicked. I’m so disappointed but yet so proud.Matsui actually has a video on their website that explains the process (at least in part).

Matsui Clays

One way to confirm that the chips were injection molded would be to take several chips and closely compare their edge spots. Edge spots made by compression molding will have minor variations from chip to chip, so that every chip is unique. Edge spots made by injection molding will be the same from chip to chip with high precision, so that every chip is identical. You can see this difference by looking very closely at some Paulsons and then some china clays.

I agree with this in general. However, it is possible to design in some "variability" in an injection mold process. The Bud Jones S2 chips I have clearly have some variability in "spot" sizes and shapes on the rolling edges of the chip. Likely they have been designed that way, but it gives the appearance of a bit of randomness in the process. It is a faux randomness, because the variations are likely repeated in the exact same pattern that you wouldn't quite notice in a random stack or splash pot.

Jeff in Iowa

Pair

99% of old clays that aren't Paulson or TRK, are Burt Co. There were only ever seven manufacturers that made clay chips, but you can boil that list down to 4 if you want to.

Burt Co/ASM/CPC

Paulson

TRK

Matsui

BCC

USPC

Hispania

You can condense that list to just Burt Co, Paulson, Matsui, and TRK; as BCC just used old Paulson equipment and methods, Hispania bought all of their equipment from Burt Co, and USPC sold all their equipment to Burt Co.

Nice pickup. I like the old hourglass mold, it has a smaller recess and a nicer feel compared to the current hourglass mold, which is in my bottom three molds for CPC.

Hunt & Co. in Chicago is at least one overlooked company that also made compression clay chips.. They produced chips from the 1920s until the 1960s on the monarch mold and various chain molds.

You can read a short 2001 article written by Howard Herz about the company here; http://www.ccgtcc-ccn.com/Gaming Checks.pdf

It states that the company began to produce these chips in the 1930s, but in a later article, Herz identifies them as using at least one of the molds beginning in the early 1920s and before USPC began manufacturing that type of chip in the late 1920s.

Interesting that at least when that article was written, the owners of the company still had the chip molds and hydraulic presses used to make chips on those molds. I wonder whatever happened to them.

Last edited:

Similar threads

- Replies

- 3

- Views

- 1K

- Locked

- Replies

- 4

- Views

- 579

- Replies

- 37

- Views

- 3K