I ordered samples on Wednesday and got them today. I am really looking forward to the rest of this project.

This first round was intended to get clarity on what elements work and don't work. We got the clarity we need and are having a debate on the final design elements.

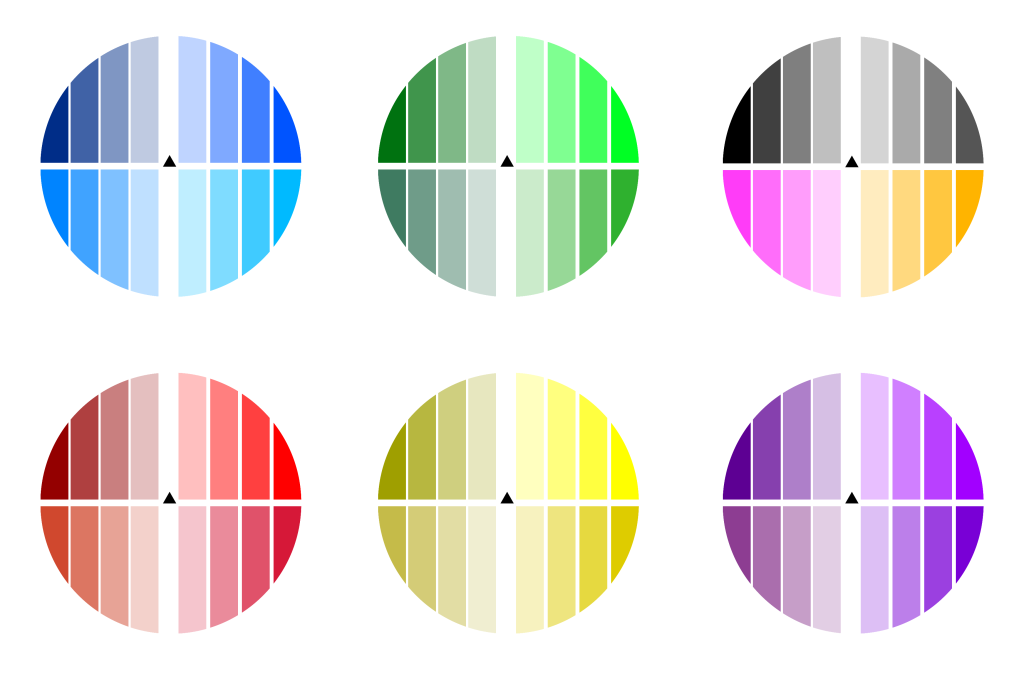

As we continue the debate, I am going to send for some color samples. As you can see in the images below, what the chips looks like vs the printed version is significantly different. Every chip is considerably darker.

I created these swatch chips to settle on colors. I have no idea what color will do what when printed so there are 16 hues of each color. I'll order 6 chips total with a different color combination between front and back, and two of each chip so I can compare hues against each other. Yes, there are a lot of colors crammed into a 1.5" chip, but I have good eyesight and hue delineation

After this I'll settle on final design and color set and request the final proofs (I hope).

Am I missing anything that I should be thinking about?

This first round was intended to get clarity on what elements work and don't work. We got the clarity we need and are having a debate on the final design elements.

As we continue the debate, I am going to send for some color samples. As you can see in the images below, what the chips looks like vs the printed version is significantly different. Every chip is considerably darker.

I created these swatch chips to settle on colors. I have no idea what color will do what when printed so there are 16 hues of each color. I'll order 6 chips total with a different color combination between front and back, and two of each chip so I can compare hues against each other. Yes, there are a lot of colors crammed into a 1.5" chip, but I have good eyesight and hue delineation

After this I'll settle on final design and color set and request the final proofs (I hope).

Am I missing anything that I should be thinking about?