Progress Update:

This is my very first build and I'm going for the raised rail as it's always been my dream since seeing them in the early days of the WSOP on ESPN

I'm sure there's going to be lots of "shoulda, coulda, woulda" moments but I'm more than happy to spend time building another one already! Haha I've completed all the woodworking necessary to get to the upholstery stage, unfortunately due to the holidays, local suppliers are closed at the moment. I'm ready for foam, vinyl and felt! My design was inspired by

@LeRoi 's stunning Ocean Club table, however, I don't have a permanent spot in the house for mine so I won't be building the same stunning set of legs .... yet...

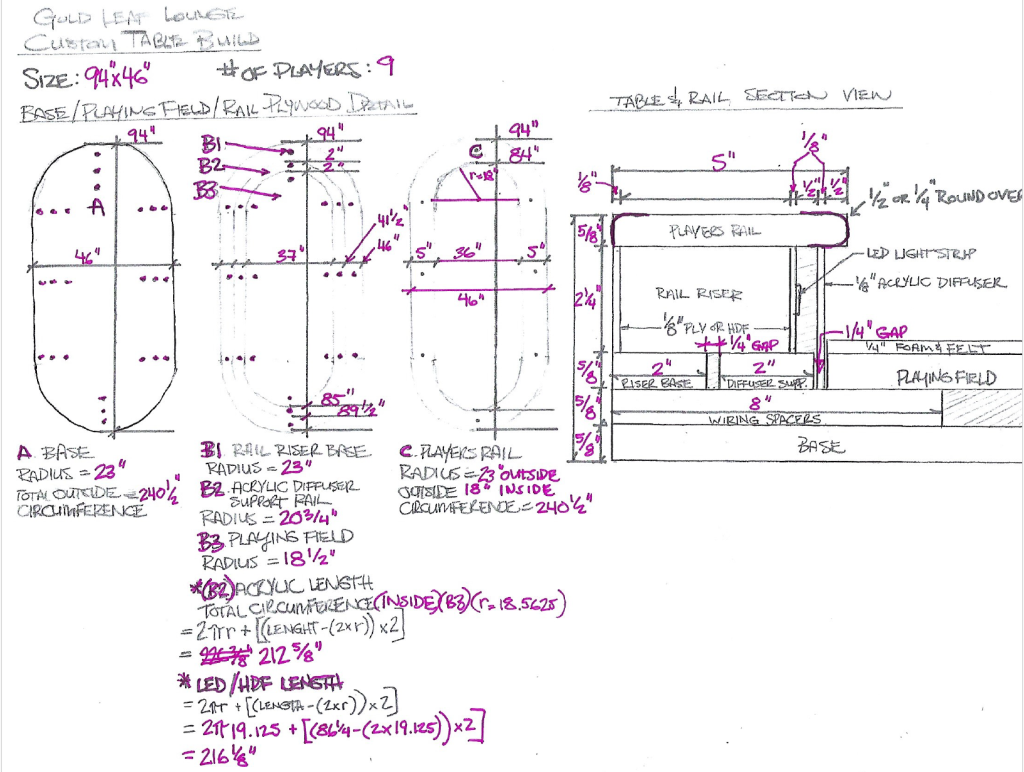

To start, I've already altered my original design (1st post) by building my table at 84" x 42" (7' x 3'-6") instead of the 94"x46" (7'-10" x 3'-10"). Yes this is a smaller size. I had to think about storage and weight as well as the typical "spare" room sizes we play in are around 10ft x 12ft so this size table would allow 8-9 comfortably with chairs in that size room. It's also built completely out of 5/8" one side sanded plywood. Firstly, I knew that I 100% wanted to install a custom felt from

@T_Chan so I was looking to save costs where I could in order to spend on what was more important to me. Secondly, I wanted to see if I could achieve a reduced weight without compromising the strength. I figured that there will be plenty of strength with the full solid base under the playing field and a glued and nailed raised rail acting like a structural perimeter beam. I've also decided to forgo the "wiring spacers" level and the USB chargers for now...

So with that... on to the build..

To start, I needed to cut down the full sheets to my rough finished dimension of 84"x42". With all 3 sheets together, I just used my circular saw and a straight edge to cut the length down. Don't worry, when I win the main event I'll scrape together some coin for a track saw but for now, my 4' level will do

Then I ripped the exact width on my table saw...

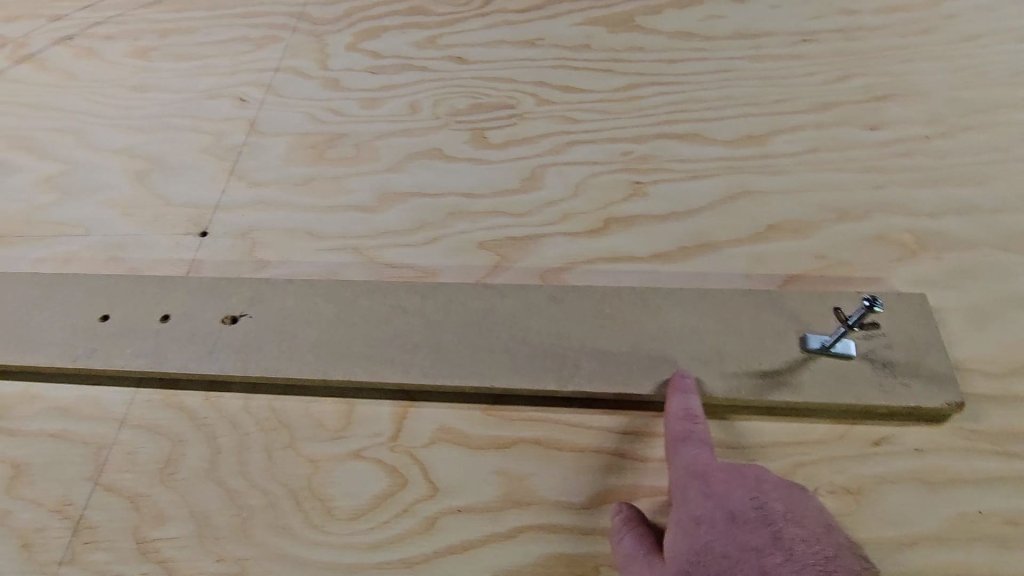

Next, I have all 3 sheets fastened together in order to cut the perimeter profile as each layer has the same outside dimension to start. For all cuts going forward, I made a simple circle cutting jig for my trim router. Ideally, it would be better to use a full sized router as the motor is bigger and can handle more cutting but again I'll buy that when I'm making my WSOP trophy case

. Even though I had my cutting jig, I still prefer and recommend to draw out all of your layout/cut lines right on the plywood before doing any cutting. Remember, cut first, measure last... or something like that...

haha But honestly, materials aren't cheap these days so it's worth grinding down some lead to make sure you have everything covered before you make your first cut!

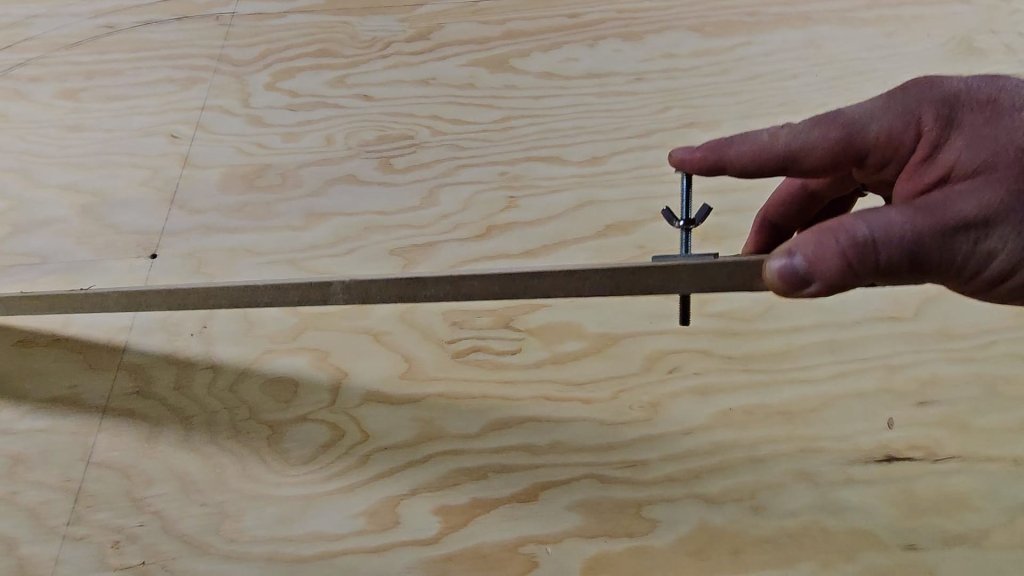

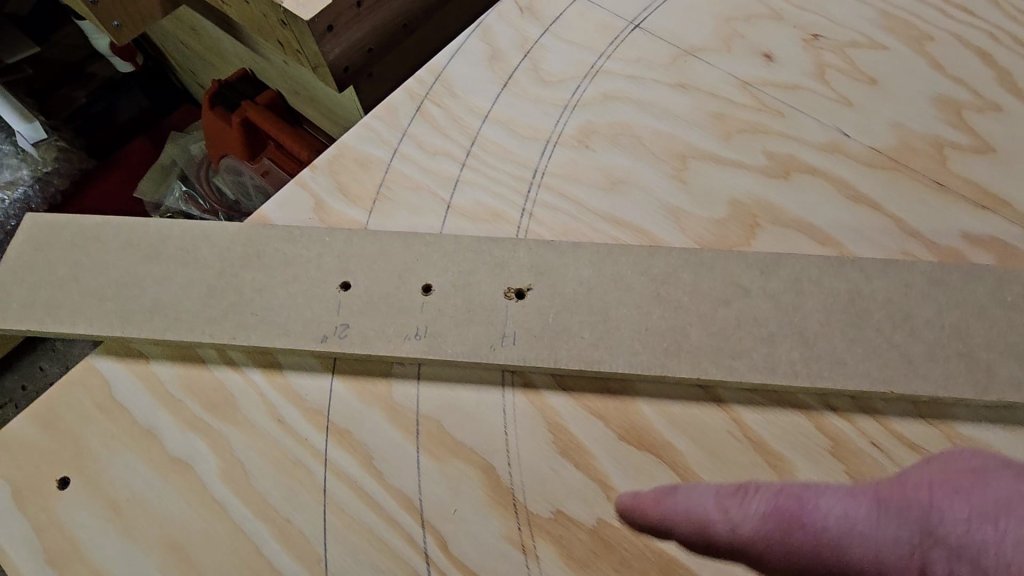

Make yourself a simple circle jig to help you draw it out by using a scrap piece that's at least 6" longer than your longest radius. Then drill a hole in the center of one end about 2" or 3" from the end. This is your pivot point where you will use a bolt or rod (I just use the same bolt clamp from my circle cutting jig) to insert into the plywood at your center points. Next, measure and mark each length of radius you need from the center of your drilled hole. Now drill holes at each of your radius measurements (making sure the hole is big enough for your preferred marking tool or pencil) Now you have a giant circle drawing tool!

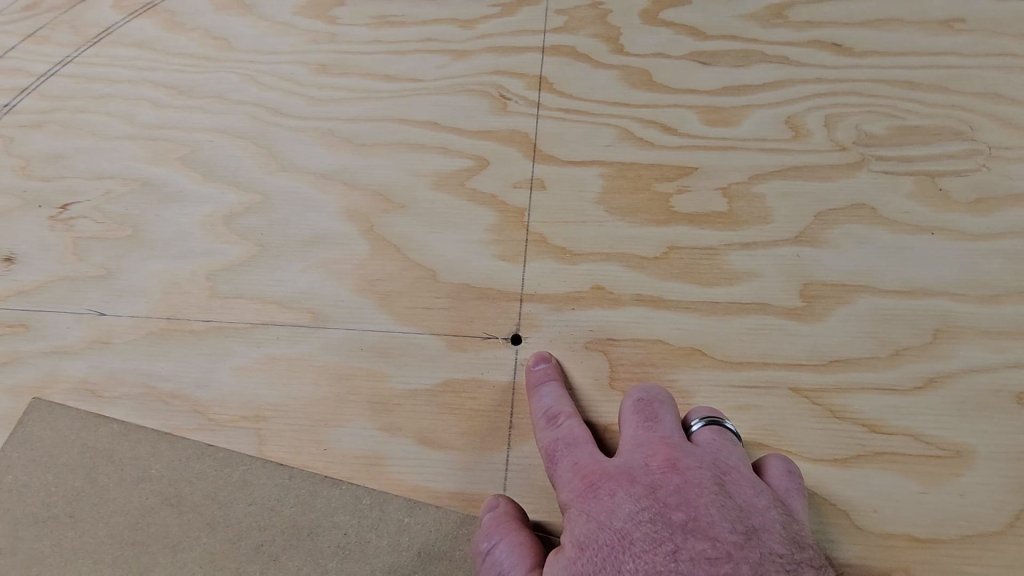

Your outside radius will be half the total width of your table. My table width is 3.5ft so the radius I need to layout is 1.75ft or 21". To start your layout, find the center of your circle by measuring from the end of the table inward the same distance as your radius, in my case 21". Then measure the same distance from the long edge of your table and wherever the 2 points meet, that's the center where all of your radius cuts will be laid out from. Once you have marked this point on both ends of the table, go ahead and drill a straight hole right through all 3 sheets the same diameter as your pivot bolt/rod, preferably no larger than 1/4". **Again, ensure your 3 sheets are flush and fastened together before you drill this hole.** Also, using your radius measurement, make a straight line across your sheet at each end, this will be your stopping point when cutting your half circles. You can also make a center line on your half circles to help you with bolt layout in later steps.

One catch while doing my layout was that I hadn't accounted for the 1/4" cut from my router bit between my 2" rings so I had to adjust my layout in order to compensate for that. The first, most outer ring is the base for the rail risers, the second ring is the support for the diffuser as the acrylic will be "pinched" between this ring and the playing field which is the inner most part of this layout. After cutting, each ring and between the playing field will have a 1/4" gap. Good catch but for this step we're just cutting the outside profile, cutting the interior rings will come afterwards. (All dimensions are posted in the "section view" in the plans from post #1)

Next, after laying out each of your radius lines, connect each one using a long straight edge.