due to the picture limitiation I have splitted the thread (i need that much pictures to describe my build  )

)

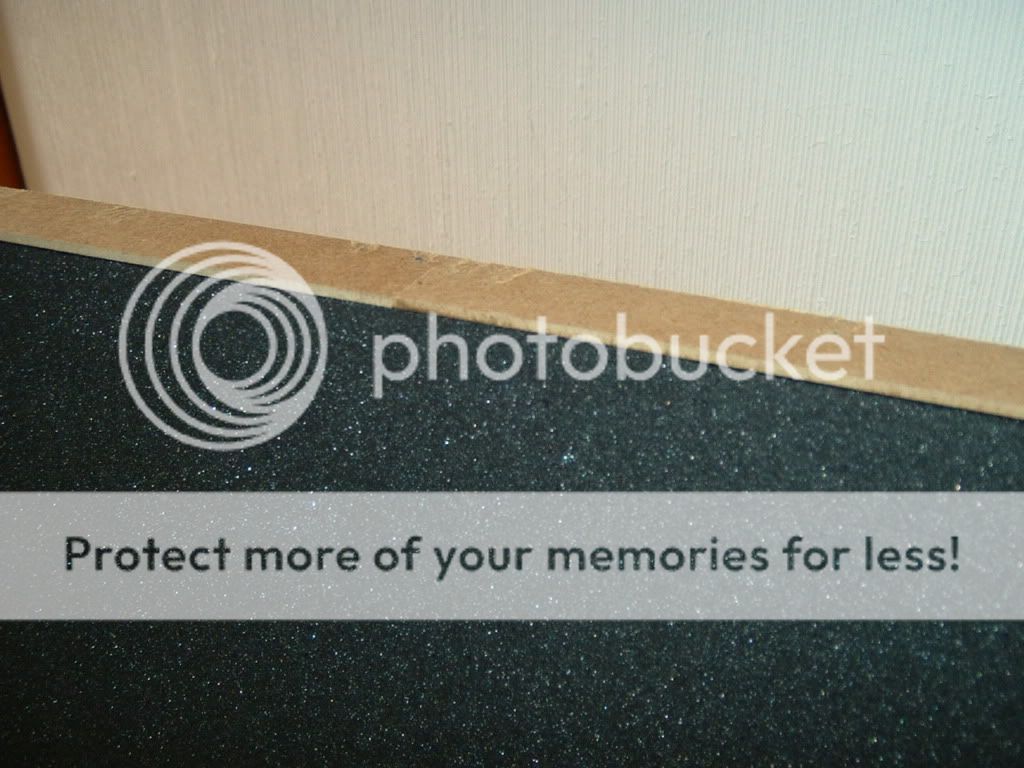

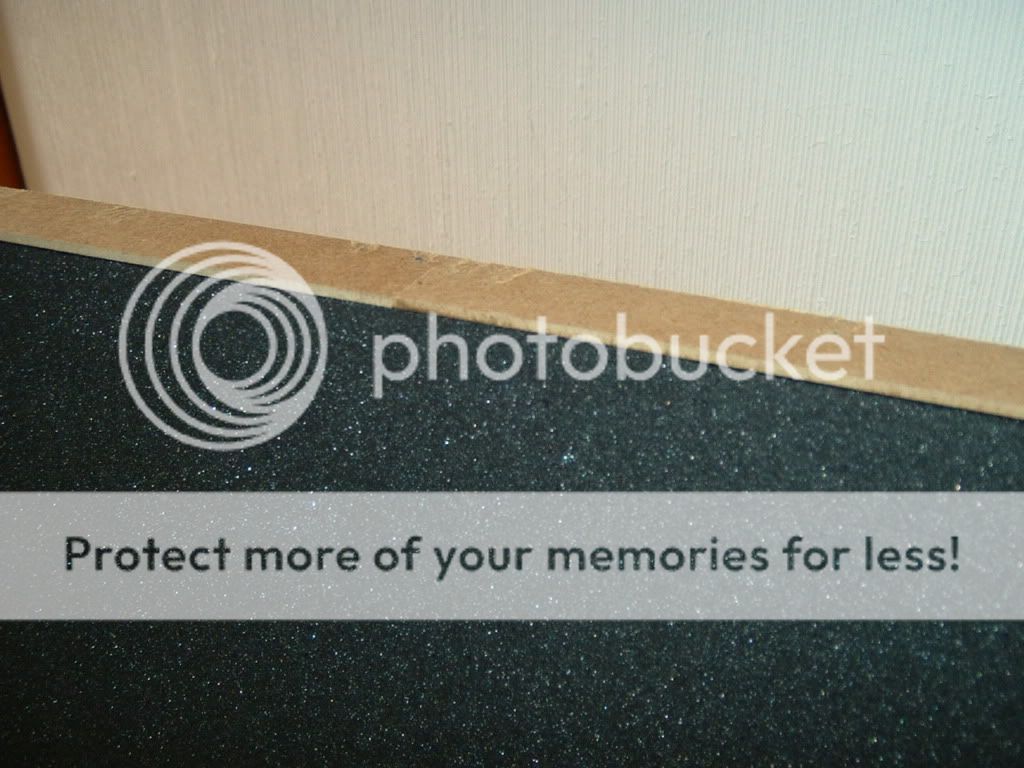

also hartboard to the outside of the rail

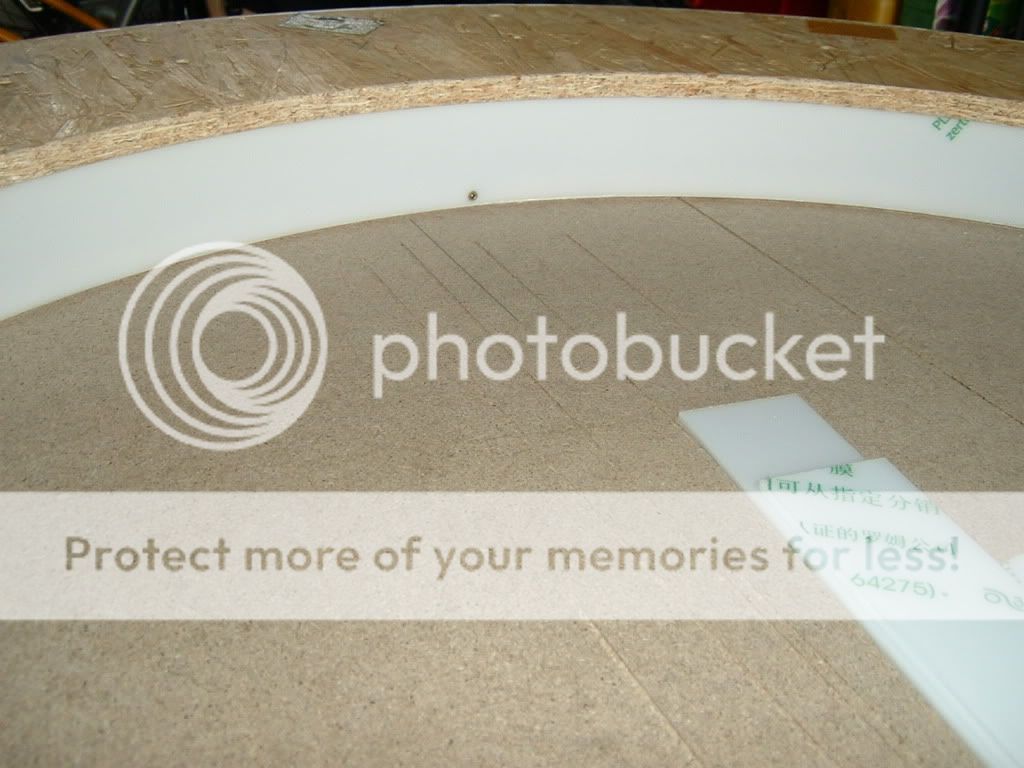

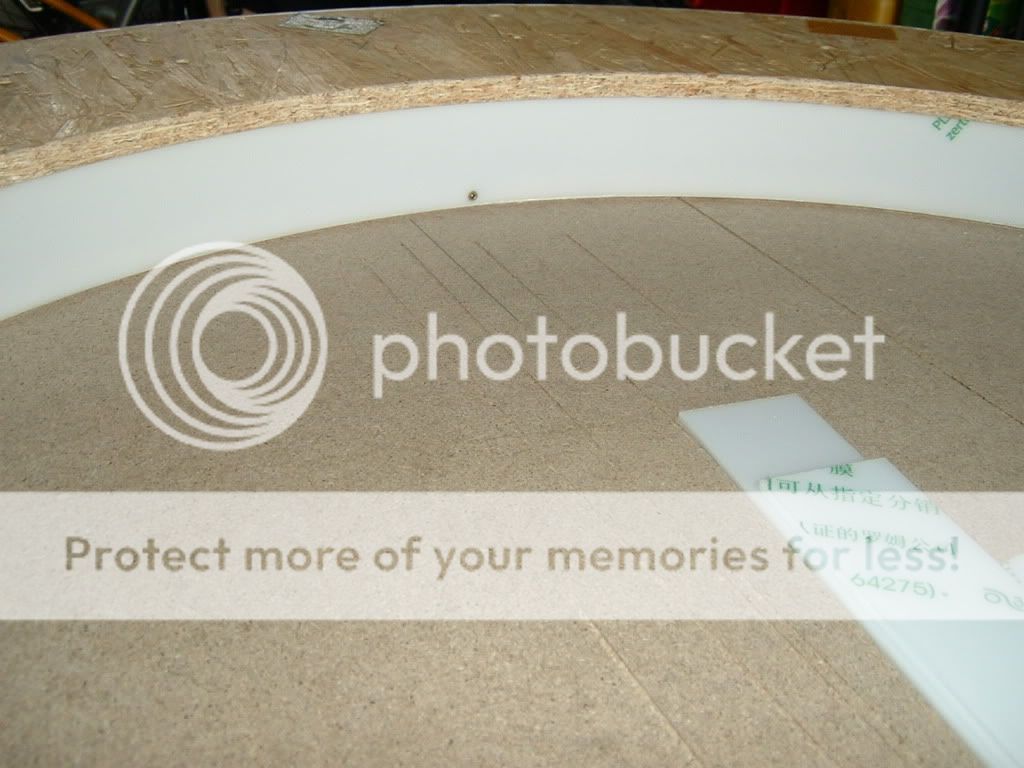

2nd cut into the playing surface board to get the lid where the plexiglass is going to screwed on and the playing surface itself.

Cut is 6mm to have enough space for the 3mm plexiglass and 2mm hartboard at the outside of the playing surface (more pics for that later)

Rail attached on the base board, also the plexiglass lid

Plexiglass srewed to the lid

1st test using a rope light

upholstering the rail (foam only to the top)

hartboard to the outside of the playing board (not to impress the foam on the edges)

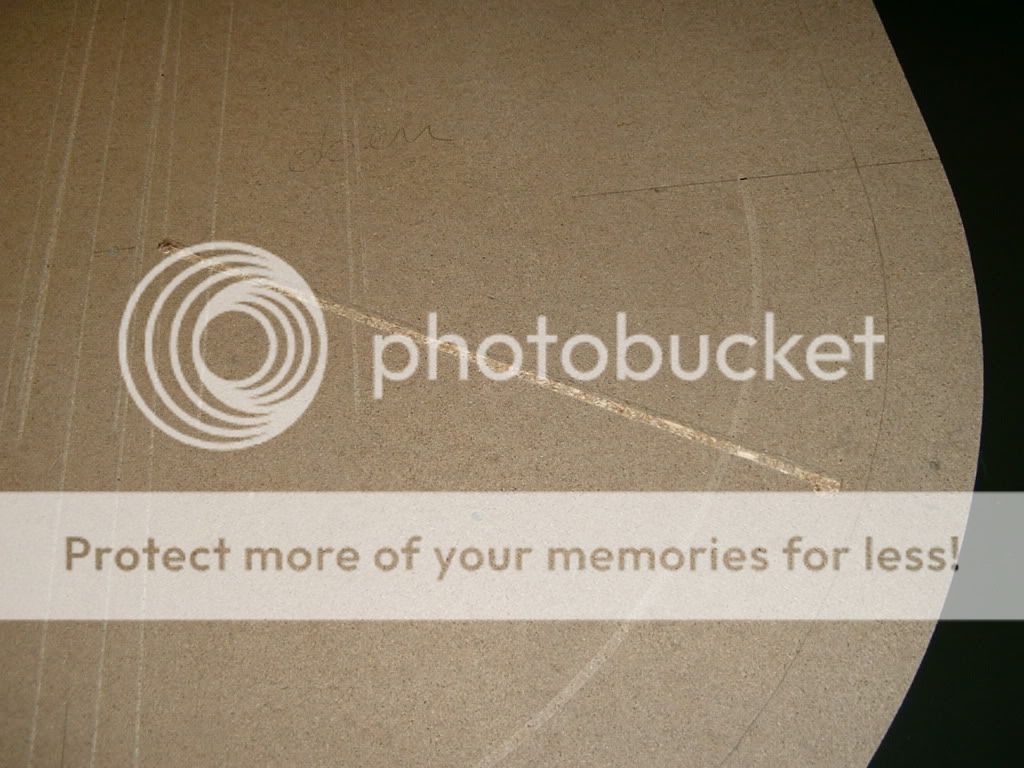

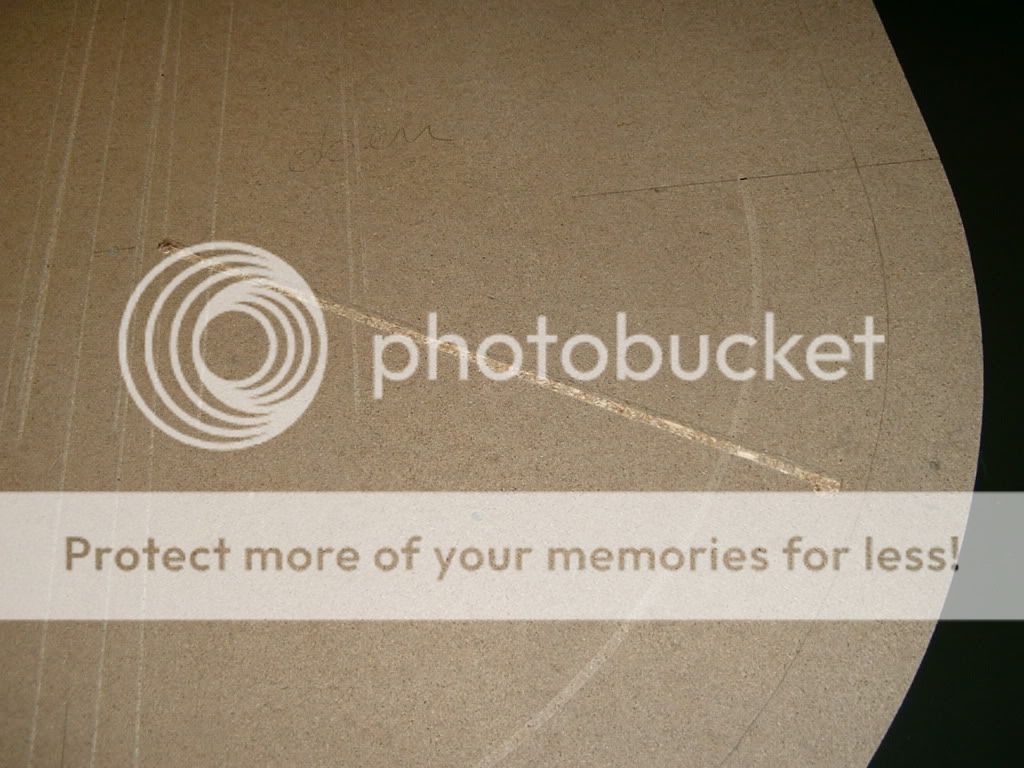

routing a channel for the LED power cord

now the LED Strip is glued into the rail

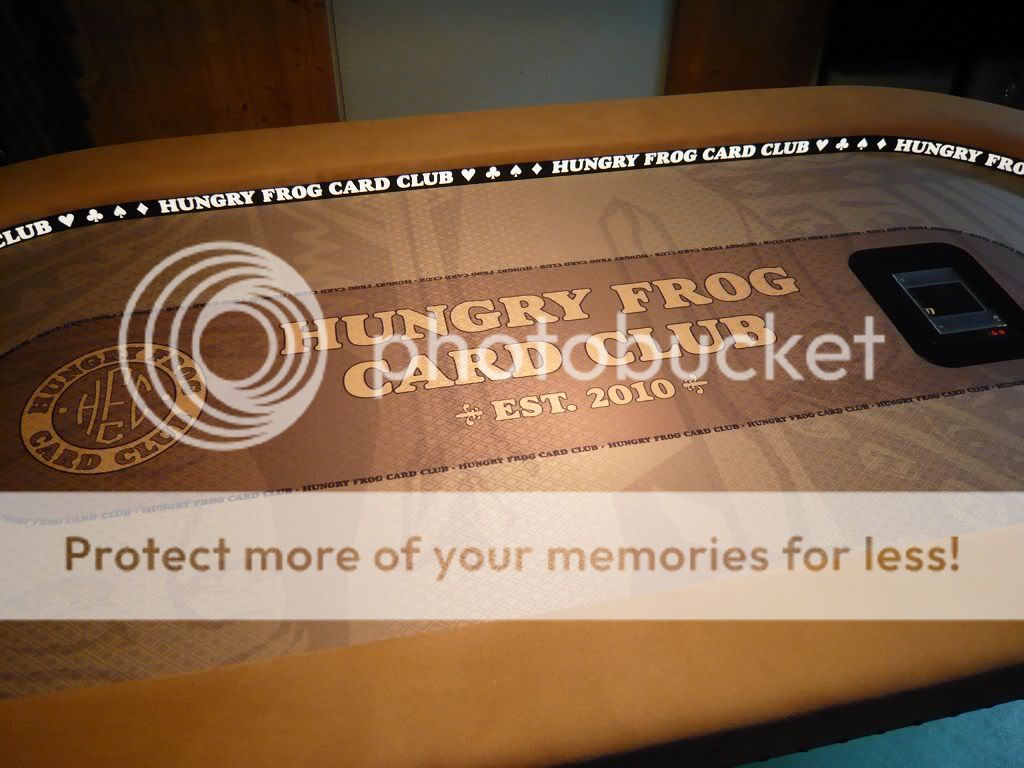

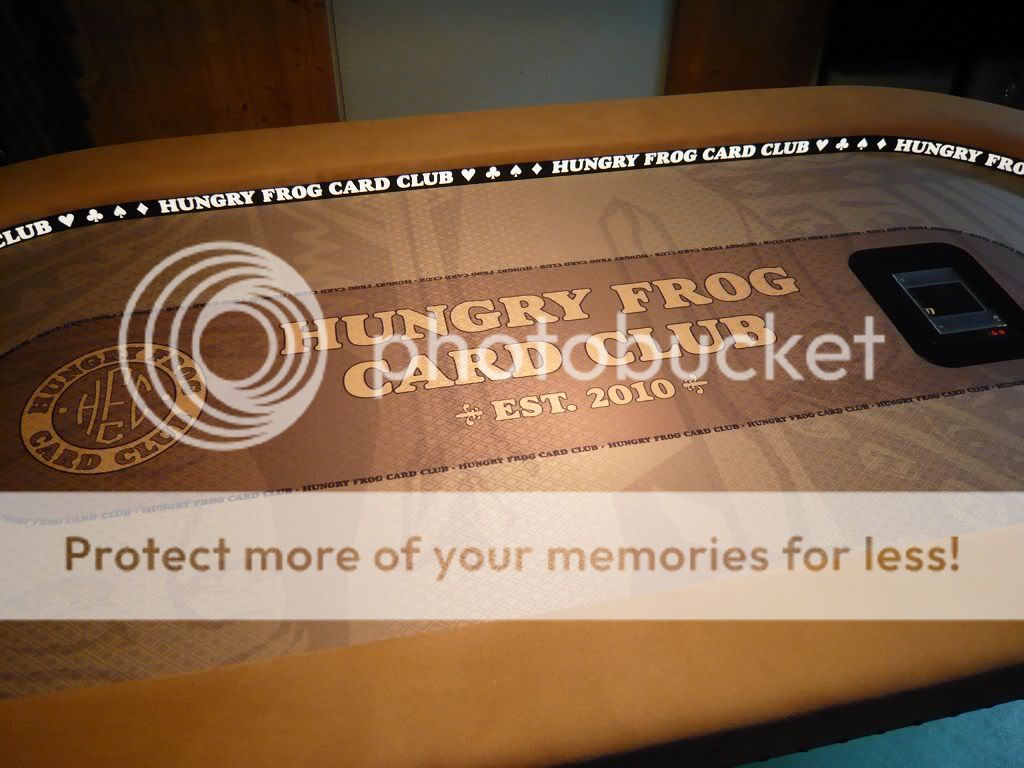

stickers attached to the plaxiglass

and final assembling

also hartboard to the outside of the rail

2nd cut into the playing surface board to get the lid where the plexiglass is going to screwed on and the playing surface itself.

Cut is 6mm to have enough space for the 3mm plexiglass and 2mm hartboard at the outside of the playing surface (more pics for that later)

Rail attached on the base board, also the plexiglass lid

Plexiglass srewed to the lid

1st test using a rope light

upholstering the rail (foam only to the top)

hartboard to the outside of the playing board (not to impress the foam on the edges)

routing a channel for the LED power cord

now the LED Strip is glued into the rail

stickers attached to the plaxiglass

and final assembling