Making and Attaching the Legs

The final portion of the project is to make the legs. You have two basic design choices for the ends - flared or straight. If the ends are straight, once you glue the boards together, you're all set. If they're flared, you have more work to do. I went with flared ends in my table.

Make the legs to proper width by gluing three boards together. Make them wide enough so that after they're glued up, they will be exactly as wide as you want the leg to be after minor sanding. I recommend using three boards, since the leg width will probably end up being between 2" and 2.5". This way, you can use 1 inch stock; there's no need to buy more expensive 2 inch or thicker stock.

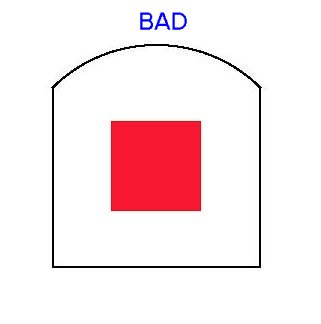

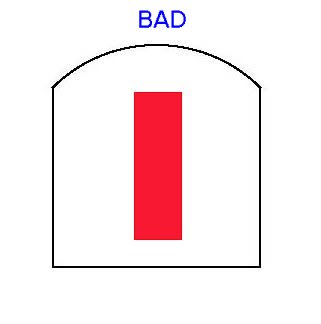

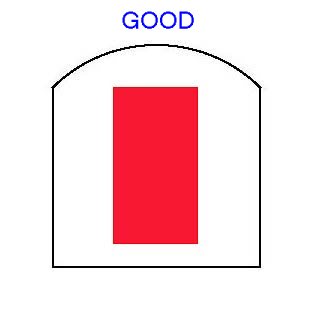

When you were designing the column shoulders and legs, you should have selected a suitable cross-section for the legs. The cross-section should neither be too wide or too high in comparison to the column's shoulder. The areas around the column should look pleasing to the eye. Refer to the following diagrams. Remember when you're locating the holes in the columns and the legs for the bolts, that there is some space from the bottom of the leg to the bottom of the column.

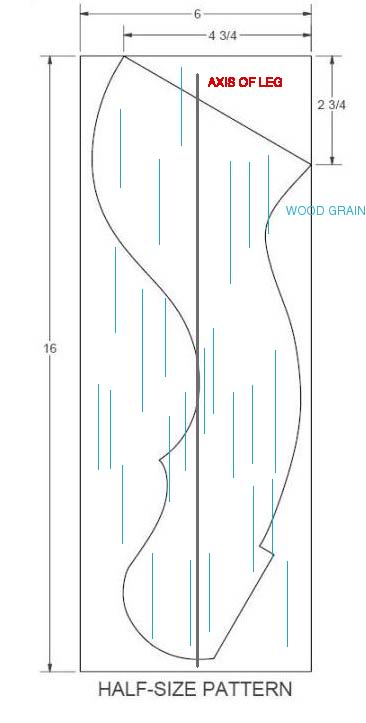

When you are ready to cut the main body of the legs, you want the axis of the leg to be parallel to the grain of the wood, in order to minimize shearing and maximize strength. Make a pattern out of cardboard and trace the outline on each leg and cut them out. Sand them until they all match when lined up against each other.

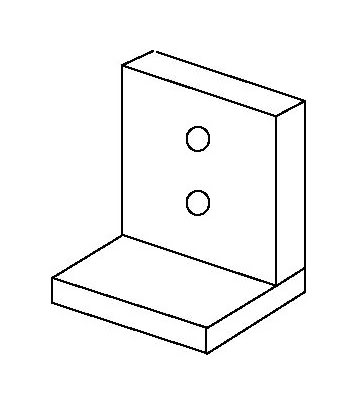

Make jigs for the bolt holes. You'll need one jig for the leg and another for the column. You want to use jigs to assure the holes are matched up as perfectly as possible so as to minimize wobbling. Mine had lips on the bottom and were the same width as the piece they were up against, so that I could feel when they were in the proper location. Drill holes in them large enough to fit an awl.

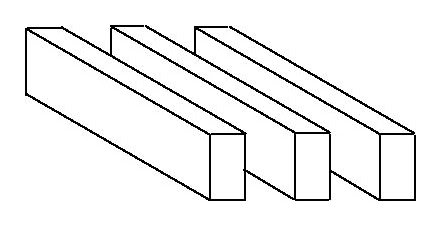

This is what the jigs look like. Tap the center points with a hammer. Remember that the distances between holes in each jig should be identical! Drill holes in the legs and columns using brad point bits; these won't stray and make clean cuts. Size the holes for the anchor bolts large enough so that it takes some effort to screw them in.

When you drill the holes for the legs, clamp them in a jig like the one shown below. The jig lets you work on both ends; sculpting one end and drilling the anchor bolt holes in the other end. When drilling the anchor bolt holes, to get the surface level with the drill press, use a small level and C-clamp the piece tight to the sides of the jig. You can clamp the jig to your work table and clamp the leg into the jig to keep it stationery.

Before you drill bolt holes in the column, mark the sides to be drilled with masking tape, so you will rotate it correctly. If you forget where you are when drilling, you might drill in one of the wrong sides. You'll save yourself a lot of time in repairing the holes and also keep your project mistake-free. If the shoulders at the top and bottom are identical in size, you can hide the inferior ones at the top, so that they are hidden by the tabletop.

For my flared leg ends, I built cubes which fit onto the leg bodies; I attached them together using dowels. I made top and side profile patterns of the ends and traced the shapes on the cube. Then, I cut as much of the excess away with a band-saw.

I finished the ends with hand tools. First, I made a jig to secure the piece. I clamped the jig to my work table and clamped the leg into the jig. I made the jig so that I could work on both ends; sculpting one end and drilling the anchor bolt holes in the other end. I numbered each leg and arranged them in order on the table. I worked on a small section of the end and moved on to the next piece. After I completed the round, I inspected all pieces and reworked the pieces until I was satisfied they matched up well.

If my work session was finished, I wrote down which section was being worked on, and which piece was next in line to be worked on. This was my first time at sculpting, and I figured this was the best way for me to make them identical.

Use anchor bolts to attach the legs to the columns. Anchor bolts have two different threads; one screws into wood, the other screws a nut; there will be a small section in the middle which is smooth. Select a size that has enough space to go through your column wall and leaves length for the nut. Use a sturdy diameter, don't go small and cheap. Grind down opposite sides of the smooth

section so it fits into an adjustable wrench; this is how you'll install the bolts to the legs.

When grinding, hold the bolt with pliers, since the heat that is generated will burn your fingers. Before inserting the anchor bolts, drop some gorilla glue inside the holes. Once the anchor bolts are in, you will never want to remove them. Attach the legs to the column using a washer and a nut.

If your design includes pedestal caps, you're ready to install them now. Drill screw holes in the sides of the column without legs, otherwise the screws might run into the anchor bolts.

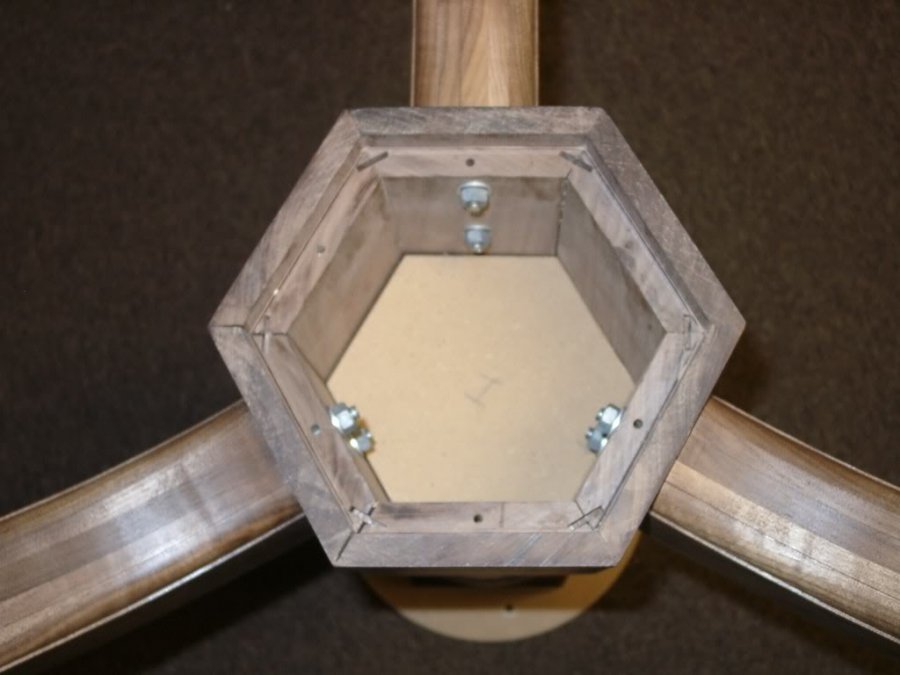

Attach the mounting plate with screws and the finished product should resemble this:

Pedestal construction is not for the impatient or faint of heart, but once you master it, is most gratifying. You can truly say your table is 100% custom built.

The final portion of the project is to make the legs. You have two basic design choices for the ends - flared or straight. If the ends are straight, once you glue the boards together, you're all set. If they're flared, you have more work to do. I went with flared ends in my table.

Make the legs to proper width by gluing three boards together. Make them wide enough so that after they're glued up, they will be exactly as wide as you want the leg to be after minor sanding. I recommend using three boards, since the leg width will probably end up being between 2" and 2.5". This way, you can use 1 inch stock; there's no need to buy more expensive 2 inch or thicker stock.

When you were designing the column shoulders and legs, you should have selected a suitable cross-section for the legs. The cross-section should neither be too wide or too high in comparison to the column's shoulder. The areas around the column should look pleasing to the eye. Refer to the following diagrams. Remember when you're locating the holes in the columns and the legs for the bolts, that there is some space from the bottom of the leg to the bottom of the column.

When you are ready to cut the main body of the legs, you want the axis of the leg to be parallel to the grain of the wood, in order to minimize shearing and maximize strength. Make a pattern out of cardboard and trace the outline on each leg and cut them out. Sand them until they all match when lined up against each other.

Make jigs for the bolt holes. You'll need one jig for the leg and another for the column. You want to use jigs to assure the holes are matched up as perfectly as possible so as to minimize wobbling. Mine had lips on the bottom and were the same width as the piece they were up against, so that I could feel when they were in the proper location. Drill holes in them large enough to fit an awl.

This is what the jigs look like. Tap the center points with a hammer. Remember that the distances between holes in each jig should be identical! Drill holes in the legs and columns using brad point bits; these won't stray and make clean cuts. Size the holes for the anchor bolts large enough so that it takes some effort to screw them in.

When you drill the holes for the legs, clamp them in a jig like the one shown below. The jig lets you work on both ends; sculpting one end and drilling the anchor bolt holes in the other end. When drilling the anchor bolt holes, to get the surface level with the drill press, use a small level and C-clamp the piece tight to the sides of the jig. You can clamp the jig to your work table and clamp the leg into the jig to keep it stationery.

Before you drill bolt holes in the column, mark the sides to be drilled with masking tape, so you will rotate it correctly. If you forget where you are when drilling, you might drill in one of the wrong sides. You'll save yourself a lot of time in repairing the holes and also keep your project mistake-free. If the shoulders at the top and bottom are identical in size, you can hide the inferior ones at the top, so that they are hidden by the tabletop.

For my flared leg ends, I built cubes which fit onto the leg bodies; I attached them together using dowels. I made top and side profile patterns of the ends and traced the shapes on the cube. Then, I cut as much of the excess away with a band-saw.

I finished the ends with hand tools. First, I made a jig to secure the piece. I clamped the jig to my work table and clamped the leg into the jig. I made the jig so that I could work on both ends; sculpting one end and drilling the anchor bolt holes in the other end. I numbered each leg and arranged them in order on the table. I worked on a small section of the end and moved on to the next piece. After I completed the round, I inspected all pieces and reworked the pieces until I was satisfied they matched up well.

If my work session was finished, I wrote down which section was being worked on, and which piece was next in line to be worked on. This was my first time at sculpting, and I figured this was the best way for me to make them identical.

Use anchor bolts to attach the legs to the columns. Anchor bolts have two different threads; one screws into wood, the other screws a nut; there will be a small section in the middle which is smooth. Select a size that has enough space to go through your column wall and leaves length for the nut. Use a sturdy diameter, don't go small and cheap. Grind down opposite sides of the smooth

section so it fits into an adjustable wrench; this is how you'll install the bolts to the legs.

When grinding, hold the bolt with pliers, since the heat that is generated will burn your fingers. Before inserting the anchor bolts, drop some gorilla glue inside the holes. Once the anchor bolts are in, you will never want to remove them. Attach the legs to the column using a washer and a nut.

If your design includes pedestal caps, you're ready to install them now. Drill screw holes in the sides of the column without legs, otherwise the screws might run into the anchor bolts.

Attach the mounting plate with screws and the finished product should resemble this:

Pedestal construction is not for the impatient or faint of heart, but once you master it, is most gratifying. You can truly say your table is 100% custom built.