Constructing the staves and splines

You'll need to determine the column's diameter, number of sides, and leg design. Once you know the diameter of the column(s), you can determine the actual width of the staves, based on the style of column (hexagon or octagon). For a hexagon style, the staves are (.5 x diameter) wide. For an octogon, the staves are (.383 x diameter) wide. Remember, these are the final dimensions. You'll need to allow a little extra width when trimming them down to final size.

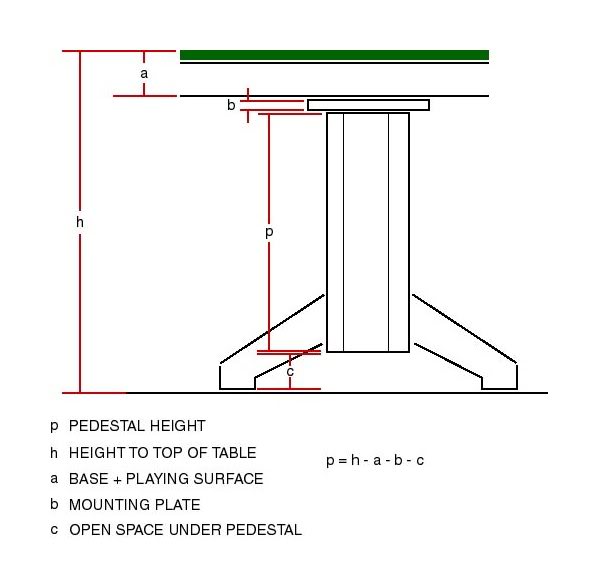

Calculate the column height by the formula in the following diagram. If your table includes other design differences, be sure to include those dimensions in your calculation. Standard table heights are between 28" and 30". You pedestal height should probably be close to 24" when all is said and done.

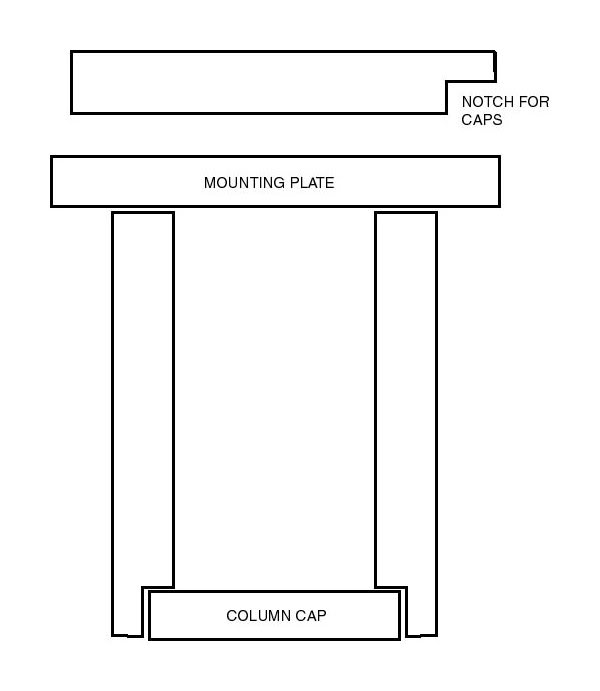

You can cut the staves to the actual height. When you assemble them, you should be able to match them up so they aren't going to need any major trimming after assembly. If you like, you can add an extra 1/8" for trimming the ends. You're going to want the stave blanks to be as identical as possible. Plane each piece and 90 degree joint and cut each piece to identical dimensions. Try not to plane the thickness, so that you maximize your working profile area. If you want to include a cap for the bottom of the column, cut notches in each stave on the table saw before assembly. These caps will be screwed into place.

Before you begin the cuts, arrange the pieces the optimum way you'd like the pieces to be seen. You can hide blemishes and imperfections inside and alternate the ones with inferior ends so they can be hidden by the legs or out of view at the upper area of the column. You might want to mark the interiors, but number them in sequence. If the top and bottom portions of the ends aren't

identical, you should mark the top end. This way, you can always rearrange them if they get mixed up.

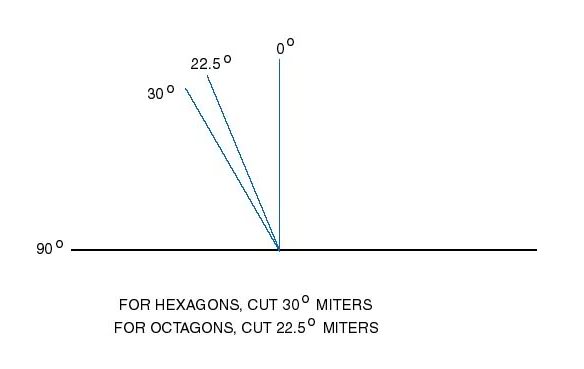

Now you can start with the miter cuts. A friend cut my staves on his CNC router table, so I had perfect miters. The other option is to make them using a table saw. For hexagons, you make 60 degree cuts; for octagons, you make 67.5 degree cuts.

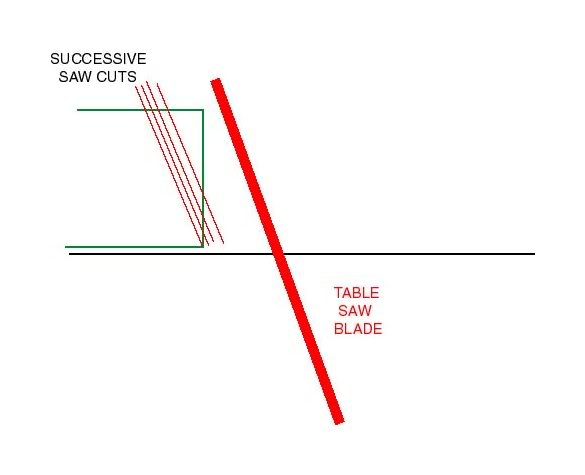

I'll assume you will be using a table saw for your miters. You'll want to do this in a way that eliminates binding or shifting of the piece in the process to ensure as smooth a cut as possible. It's not realistic to expect to run the piece through once; there's just too much wood, even with the sharpest blade. I recommend making successive cuts.

The important thing is to set the saw blade as precisely as possible. You'll want to use scrap wood for setting up the proper angle for the blade.

TIP:

To find the perfect angle, crank the saw blade to its highest position. Set the blade to the desired angle. Use a piece of scrap wood just high enough so that the saw will cut through it entirely. Cut the six or eight pieces and make these the same width. After all pieces are cut, form the pieces to the desired shape.

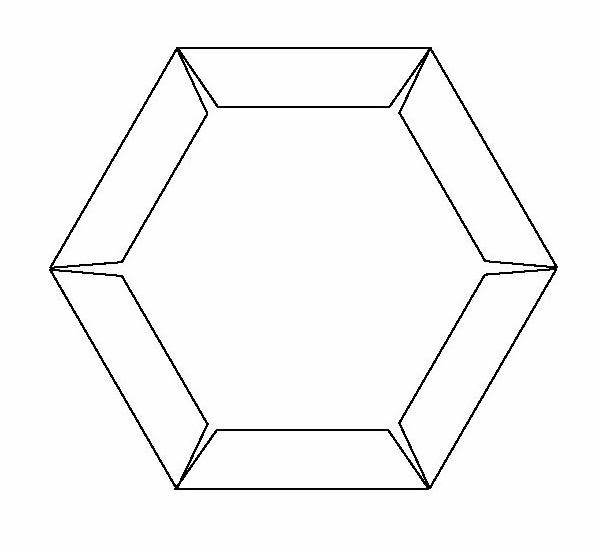

If the angle is too shallow, this will be the result:

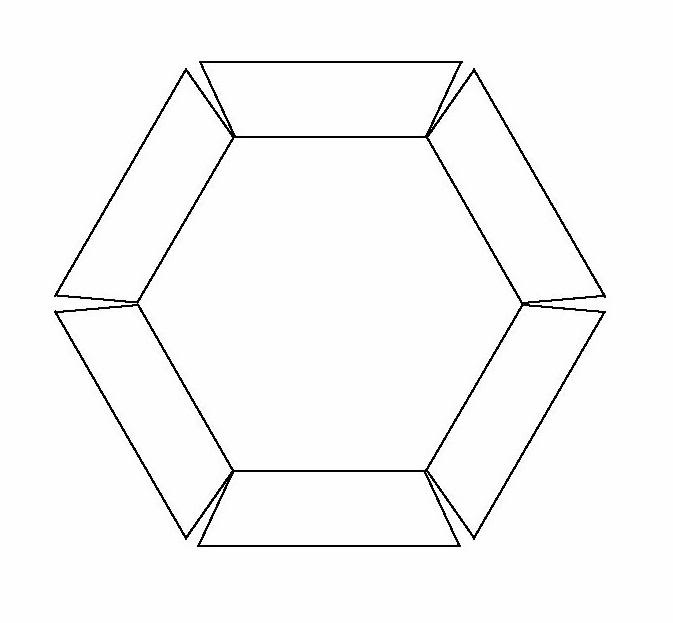

If the angle is too steep, this will be the result:

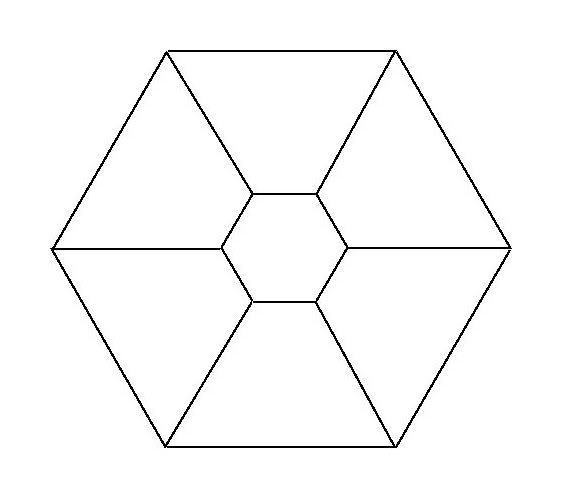

You should repeat this process until you get this result:

The purpose in using a wide test piece is that it exaggerates the miter cut to let you see any openings. It's important to get the pieces to match perfectly to get the column as strong as possible when gluing it up. If there is any opening, the strength of the column will be compromised.

TIP:

Make the final miter cut trim material about 1/2 the width of the saw blade. This will remove a little wood and ensure the cut is smooth.

After you have finished the miter cuts, you can make the splines. The splines allow for alignment of the staves and also improve the column's strength. They will be glued into place. You will need as many splines as you have sides to the column - six or eight.

Splines should be made out of the same wood as the staves. This is in the event you turn the column down too much and hit the spline; it will be concealed well. For example, if you use dark-stained oak staves with a pine spline, you will see the difference right away.

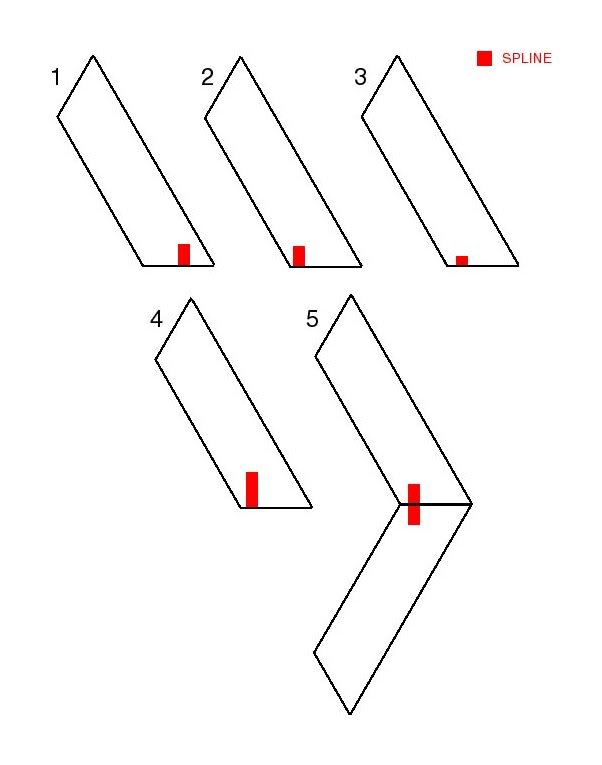

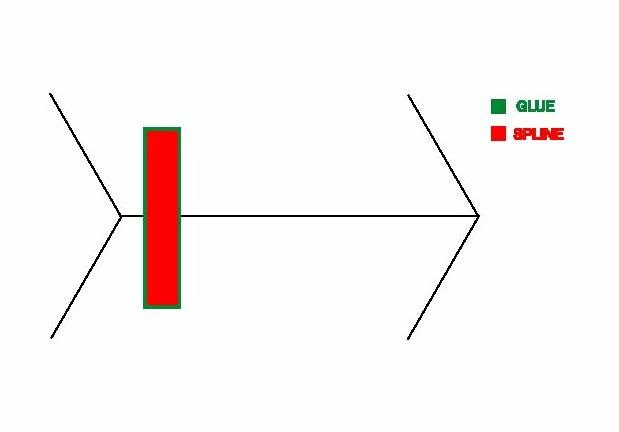

Channels for the splines can be made on the table saw. You don't want the channel too close to either edge, or not the proper height. The next diagram shows examples of bad spline channels and a good one. The first four examples are too close to the edges, too shallow or too high. The fifth one is perfect. Just make sure you locate and size it properly.

You can make the splines on a table saw or belt sander. They should be the same height as the staves, since they will run all the way up the staves. The splines should be nearly twice the height of your table saw cut. You should be able to put two staves together and slide the spline through the opening.

TIP:

The splines should fit into the staves and leave just enough space to fit a business card in. If the splines are too tight, they will prevent glue from forming around them and instead trap all the glue in the channel, making it difficult to clamp the staves together. When the splines are the correct size, glue will flow around them and allow the staves to close in on each other when you're clamping them for a perfect fit.

You are now all set to assemble the staves and splines.

You'll need to determine the column's diameter, number of sides, and leg design. Once you know the diameter of the column(s), you can determine the actual width of the staves, based on the style of column (hexagon or octagon). For a hexagon style, the staves are (.5 x diameter) wide. For an octogon, the staves are (.383 x diameter) wide. Remember, these are the final dimensions. You'll need to allow a little extra width when trimming them down to final size.

Calculate the column height by the formula in the following diagram. If your table includes other design differences, be sure to include those dimensions in your calculation. Standard table heights are between 28" and 30". You pedestal height should probably be close to 24" when all is said and done.

You can cut the staves to the actual height. When you assemble them, you should be able to match them up so they aren't going to need any major trimming after assembly. If you like, you can add an extra 1/8" for trimming the ends. You're going to want the stave blanks to be as identical as possible. Plane each piece and 90 degree joint and cut each piece to identical dimensions. Try not to plane the thickness, so that you maximize your working profile area. If you want to include a cap for the bottom of the column, cut notches in each stave on the table saw before assembly. These caps will be screwed into place.

Before you begin the cuts, arrange the pieces the optimum way you'd like the pieces to be seen. You can hide blemishes and imperfections inside and alternate the ones with inferior ends so they can be hidden by the legs or out of view at the upper area of the column. You might want to mark the interiors, but number them in sequence. If the top and bottom portions of the ends aren't

identical, you should mark the top end. This way, you can always rearrange them if they get mixed up.

Now you can start with the miter cuts. A friend cut my staves on his CNC router table, so I had perfect miters. The other option is to make them using a table saw. For hexagons, you make 60 degree cuts; for octagons, you make 67.5 degree cuts.

I'll assume you will be using a table saw for your miters. You'll want to do this in a way that eliminates binding or shifting of the piece in the process to ensure as smooth a cut as possible. It's not realistic to expect to run the piece through once; there's just too much wood, even with the sharpest blade. I recommend making successive cuts.

The important thing is to set the saw blade as precisely as possible. You'll want to use scrap wood for setting up the proper angle for the blade.

TIP:

To find the perfect angle, crank the saw blade to its highest position. Set the blade to the desired angle. Use a piece of scrap wood just high enough so that the saw will cut through it entirely. Cut the six or eight pieces and make these the same width. After all pieces are cut, form the pieces to the desired shape.

If the angle is too shallow, this will be the result:

If the angle is too steep, this will be the result:

You should repeat this process until you get this result:

The purpose in using a wide test piece is that it exaggerates the miter cut to let you see any openings. It's important to get the pieces to match perfectly to get the column as strong as possible when gluing it up. If there is any opening, the strength of the column will be compromised.

TIP:

Make the final miter cut trim material about 1/2 the width of the saw blade. This will remove a little wood and ensure the cut is smooth.

After you have finished the miter cuts, you can make the splines. The splines allow for alignment of the staves and also improve the column's strength. They will be glued into place. You will need as many splines as you have sides to the column - six or eight.

Splines should be made out of the same wood as the staves. This is in the event you turn the column down too much and hit the spline; it will be concealed well. For example, if you use dark-stained oak staves with a pine spline, you will see the difference right away.

Channels for the splines can be made on the table saw. You don't want the channel too close to either edge, or not the proper height. The next diagram shows examples of bad spline channels and a good one. The first four examples are too close to the edges, too shallow or too high. The fifth one is perfect. Just make sure you locate and size it properly.

You can make the splines on a table saw or belt sander. They should be the same height as the staves, since they will run all the way up the staves. The splines should be nearly twice the height of your table saw cut. You should be able to put two staves together and slide the spline through the opening.

TIP:

The splines should fit into the staves and leave just enough space to fit a business card in. If the splines are too tight, they will prevent glue from forming around them and instead trap all the glue in the channel, making it difficult to clamp the staves together. When the splines are the correct size, glue will flow around them and allow the staves to close in on each other when you're clamping them for a perfect fit.

You are now all set to assemble the staves and splines.