JustinInMN

4 of a Kind

This is my 200th post. I haven't discussed my personal set on this board before, but it's time to admit what I own and how it came to be.

So about a year ago I saw this video from @Hobbyphilic.

And I figured there had to be a better way to make custom labeled chips. Shortly after, I found my way to pokerchipforum to see if I could find the least expensive way to custom print poker chips, but there wasn't really an answer. Most discussions I found were about relabing used Paulsons with @Gear labels, but I could see right away that was way deeper than I wanted to get at the time. I only host .05-10 to .25-.50, I owned a set of 800 Black Diamond ABS mixed with four aces nickels to accommodate these stakes. I liked these chips fine and considered this my first "nice set" purchase in 2011 after previously just using dice/suited chips or super diamonds. But I wanted to find out what it would take to create my own set and see if I can find the least expensive way to do it.

Blanks ($80):

So if we're chipping on the cheap, ABS plastic blanks are as cheap as it gets. (I'm sure this is where I am going to lose most readers.) I grabbed 875 blanks from discountcasinogear.com of the classic eight stripe design. (75 were just destined to be extras, probably toys for my daughter . )

. )

https://www.discountcasinogear.com/Eight-Stripe-Poker-Chips-p/51.htm

(That's my review from almost a year ago when I started this project, I see the price has since increased by a penny.)

I know ABS is not well loved here, but again, I had Black Diamonds before this so I was familiar with the design and liked it fine. (At least I liked it more than dice or suited chips.) I like the larger 1 1/4" inlay personally and I knew they stack pretty well for my purposes and should fit fine in my racks.

(I also grabbed enough 2 stripe twist chips for a cheap tournament set to put me over the $100 free shipping mark . )

. )

Labels ($30):

So I know a little bit about printing, I was a copy jockey for a while during college, so I knew Hobbyphilic's photo paper and glue method could be improved. I also have a brother 3000 series laser printer at home. I would not consider doing home printing with an inkjet printer. Even the laser printer has some issues as I would come to find, more on that later.

So I'm thinking I need a heavy weatherproof material I can run through a laser printer. I stumbled on onlinelabels.com and I went with the weatherproof polyseter with the 1.25" circle labels. Figured weatherproof was a must and I needed something with adhesive already applied so I don't add thickness to the recess.

My first run on these labels was not very successful. I came to find that home printers do not hit the perferations very well for something as precise as a poker chip inlay, despite all the effort you can put into calibrating the printer. (I am guessing @Gear 's equipment does not have this problem which is why he turns out the quality of work that pleases everyone here.) When you think about it, if you have a movement of 1/8" or more whlie the sheets are running through the printer that's about an 11% miss, and with text near the edge of the inlay, that just wasn't acceptable. So I ended up returning those and just buying full sheet labels (without the circle perforations) of the same material.

https://www.onlinelabels.com/Products/OL175LP.htm?search=ol175lp&st=s

I figured I was still getting 48 labels per sheet (enough for 24 chips) so to make 800 chips I figured 34 sheets, so I went to 45 to give myself a 30% buffer. That came to $30 shipped after I got a $5 discount on facebook .

.

Materials Summary:

So for materials, I've got about $110 into this. If I overestimate about .25 per page for printing, even if I had to use all 45 sheets, that's another $11, so $121 in materials for 800 chips, that's under .16 each.

Now all I need is my sweat equity, oh and as it turns out tools.

Tools and Handwork:

So I started with a 1 1/4" craft punch for about $9 on Amazon Prime. That worked pretty well for about 100 labels and then it became pretty difficult to get clean cuts. The heavier material started to bunch and it just didn't feel like it was cutting sharply anymore. I tried some of the sharpening methods I found online such as cutting through tin foil. Tried to clean it with WD 40 to make sure the adhesive wasn't on the blade, but nothing really helped. I didn't see purchasing 16 of these as a reasonable means to finish this project so I had to come up with another idea. After some googling, I stumbled across the idea of using a hollow punch tool. Now I guess this is typically used for making gaskets out of rubber sheets, so I figured this might be durable enough to punch poly labels.

https://www.amazon.com/Anytime-Tool...=1525227442&sr=8-5&keywords=hollow+punch+tool

I know I only needed one size in this kit, but $37 looked better than getting $160 worth of craft punches that may not last. Also it's tough to find the single punch in this size for any less locally, so I went for it.

Now when this arrived, it was pretty dull, which I knew to expect, many cutting tools aren't sharpened leaving the factory. So I decided to take the 1 1/4 inch one to a nearby tool shop and they sharpened it for about $10. So I felt this was my last resort, if this didn't work, I probably had to abandon the project. But truthfully, it worked pretty well. Here's a video.

(Warning, I apologize if my bald dome blinds you, wish I wore a hat . Also thanks to Missus JustinInMN for filming this and the other video below.)

. Also thanks to Missus JustinInMN for filming this and the other video below.)

https://drive.google.com/file/d/1FzaBvJV_1tcqxdvaZDUKwEbjhEAkPf50/view?usp=sharing

Now this still requires a good eye, and some mis-punches are still inevitable. Eventually one has to accept that the inlays won't be perfect, but at the very least, better than some of the misprints I was getting with the perforated labels. But the cuts were clean and the labels were fitting the recess perfectly. I figured this was as good as it was going to get.

So with this figured out, all that was left was labeling. Now without perferations, it takes an Xacto knife to separate the backing. Here a video on that.

https://drive.google.com/file/d/1XzONHqxGDrwNLhnczwUXaWzpSWZZtV91/view?usp=sharing

So as I mentioned in the videos I figured it was about 5 minutes to punch out a sheet of 48, or about 20 mintues to get enough labels per rack. And labelling I figured was about an hour per rack. So 80 minutes per rack times 8 racks is 640 minutes, or nearly 11 hours of hand work.

So if I had all these answers at the outset of the project and the right tools for the job this probably would have come to about $121 in materials and printing as I said above. But since I had to buy tools, pay an extra shipping charge on the labels, buy a craft punch that was basically worthless I probably have closer to $200 and the aforementioned 11 of sweat equity into this set.

Here are a few more pictures.

A word about the designs:

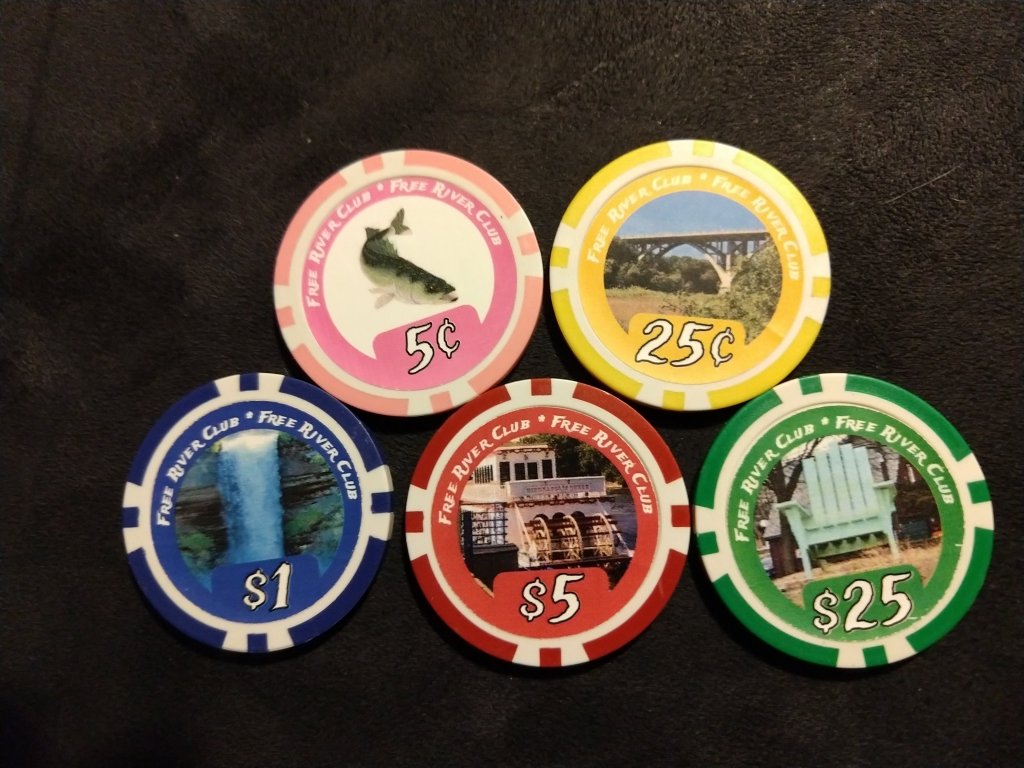

The Free River Club design is basically a local photo tour. And this is part of the process of which I'm most proud, but again, the credit for the pictures goes to the aforementioned Missus JustinInMN.

In my location in Dakota County in the Twin Cities area we are known as "South of the river" because we are separated from the Twin Cities proper and inner suburbs by the Minnesota River. So that and the concept of a "free river" card in poker was the inspiration for the name. The pictures are locations near the Minnesota and Mississippi rivers except for nickel which is just clip art of a walleye. (You can't do a Minnesota themed set without a Walleye. And maybe making them look at a fish is my passive aggressive way to mock my nickel chip players.)

The quarter is the Mendota Bridge (which carries MN-55 over the Minnesota River) near the confluence of the Minnesota and Mississippi Rivers and is the largest span in the Twin Cities area. It's one of my favorite bridges because of it's arches and from the top you can see both skylines. It also seemed to fit well on a yellow.

The single is Minnehaha Falls, one of the best natural attractions in the area and just north of the Mendota bridge form the quarter chip. This picture is taken from a small walking bridge near the base of the falls that crosses Minnehaha creek. I think this looks great on a blue chips. (I am very much team blue dollar, which was one of my frustrations with the black diamond set, the grey single and brown quarter were just too close in color, I like contrasting yellow and blue much better.)

The five is the Minneapolis Queen, a tour boat that docks at Bohemian Flats park in Minneapolis, somewhat between downtown and the University of Minnesota. The red paddle wheel I think made this a great choice for a red chip, along with the association of paddle wheel boats and old school gambling.

The twenty-five is the giant lawn chair at High Bridge Park in Saint Paul. The chair overlooks the Mississippi river at the foot of the High Bridge (which carries MN-149 toward downtown Saint Paul) and this seemed quite fitting for a green chip given how few green landmarks there are.

Summary:

So if you've stuck through this whole thing, I'm really proud of you. I bet you didn't think you'd be willing to read 1500 words on ABS chips. Here's the summary in case you took the shortcut.

Pros

Warnings

So I'm glad I went through this exercise, and I hope this set lasts a little while. I host a game every month or two only so it's probably fine for that. But I think I have the bug to get better customs down the line, probably in a year or two that will hopefully last.

To that end, in recent months on the forum, I did get a sample of the PCF Gemaco Tournament Chips that @Apache made. Also, I just ordered a sample set of ceramics from @ABC Gifts and Awards ($11 now, possibly hundreds later ) that just arrived today. Also I probably want to get a sample set of the American High Roller CPC A-mold set on which @Tommy seems to be working if they decide to do that.

) that just arrived today. Also I probably want to get a sample set of the American High Roller CPC A-mold set on which @Tommy seems to be working if they decide to do that.

https://www.pokerchipforum.com/threads/cpc-a-mold-aria-style.28820/

I already have ideas for photos for a 20 and 100, and if I ever make it up to North Branch, MN, I'll have the missus snap a picture of this for the nickel.

https://goo.gl/maps/G89NqQrsjER2

In other words, while I'm happy with the set and I'm proud I followed through on the work required, I still find myself questioning the wisdom of dumping $200 on this in the first place, now that I clearly have "the bug" and the taste for wanting to do this on better materials.

So I've answered the question on the least expensive method to do this as my contribution to the forum. I'm happy with the results, but I find myself wanting more. You decide if this contribution is brilliant, or a cautionary tale.

So about a year ago I saw this video from @Hobbyphilic.

And I figured there had to be a better way to make custom labeled chips. Shortly after, I found my way to pokerchipforum to see if I could find the least expensive way to custom print poker chips, but there wasn't really an answer. Most discussions I found were about relabing used Paulsons with @Gear labels, but I could see right away that was way deeper than I wanted to get at the time. I only host .05-10 to .25-.50, I owned a set of 800 Black Diamond ABS mixed with four aces nickels to accommodate these stakes. I liked these chips fine and considered this my first "nice set" purchase in 2011 after previously just using dice/suited chips or super diamonds. But I wanted to find out what it would take to create my own set and see if I can find the least expensive way to do it.

Blanks ($80):

So if we're chipping on the cheap, ABS plastic blanks are as cheap as it gets. (I'm sure this is where I am going to lose most readers.) I grabbed 875 blanks from discountcasinogear.com of the classic eight stripe design. (75 were just destined to be extras, probably toys for my daughter

https://www.discountcasinogear.com/Eight-Stripe-Poker-Chips-p/51.htm

(That's my review from almost a year ago when I started this project, I see the price has since increased by a penny.)

I know ABS is not well loved here, but again, I had Black Diamonds before this so I was familiar with the design and liked it fine. (At least I liked it more than dice or suited chips.) I like the larger 1 1/4" inlay personally and I knew they stack pretty well for my purposes and should fit fine in my racks.

(I also grabbed enough 2 stripe twist chips for a cheap tournament set to put me over the $100 free shipping mark

Labels ($30):

So I know a little bit about printing, I was a copy jockey for a while during college, so I knew Hobbyphilic's photo paper and glue method could be improved. I also have a brother 3000 series laser printer at home. I would not consider doing home printing with an inkjet printer. Even the laser printer has some issues as I would come to find, more on that later.

So I'm thinking I need a heavy weatherproof material I can run through a laser printer. I stumbled on onlinelabels.com and I went with the weatherproof polyseter with the 1.25" circle labels. Figured weatherproof was a must and I needed something with adhesive already applied so I don't add thickness to the recess.

My first run on these labels was not very successful. I came to find that home printers do not hit the perferations very well for something as precise as a poker chip inlay, despite all the effort you can put into calibrating the printer. (I am guessing @Gear 's equipment does not have this problem which is why he turns out the quality of work that pleases everyone here.) When you think about it, if you have a movement of 1/8" or more whlie the sheets are running through the printer that's about an 11% miss, and with text near the edge of the inlay, that just wasn't acceptable. So I ended up returning those and just buying full sheet labels (without the circle perforations) of the same material.

https://www.onlinelabels.com/Products/OL175LP.htm?search=ol175lp&st=s

I figured I was still getting 48 labels per sheet (enough for 24 chips) so to make 800 chips I figured 34 sheets, so I went to 45 to give myself a 30% buffer. That came to $30 shipped after I got a $5 discount on facebook

Materials Summary:

So for materials, I've got about $110 into this. If I overestimate about .25 per page for printing, even if I had to use all 45 sheets, that's another $11, so $121 in materials for 800 chips, that's under .16 each.

Now all I need is my sweat equity, oh and as it turns out tools.

Tools and Handwork:

So I started with a 1 1/4" craft punch for about $9 on Amazon Prime. That worked pretty well for about 100 labels and then it became pretty difficult to get clean cuts. The heavier material started to bunch and it just didn't feel like it was cutting sharply anymore. I tried some of the sharpening methods I found online such as cutting through tin foil. Tried to clean it with WD 40 to make sure the adhesive wasn't on the blade, but nothing really helped. I didn't see purchasing 16 of these as a reasonable means to finish this project so I had to come up with another idea. After some googling, I stumbled across the idea of using a hollow punch tool. Now I guess this is typically used for making gaskets out of rubber sheets, so I figured this might be durable enough to punch poly labels.

https://www.amazon.com/Anytime-Tool...=1525227442&sr=8-5&keywords=hollow+punch+tool

I know I only needed one size in this kit, but $37 looked better than getting $160 worth of craft punches that may not last. Also it's tough to find the single punch in this size for any less locally, so I went for it.

Now when this arrived, it was pretty dull, which I knew to expect, many cutting tools aren't sharpened leaving the factory. So I decided to take the 1 1/4 inch one to a nearby tool shop and they sharpened it for about $10. So I felt this was my last resort, if this didn't work, I probably had to abandon the project. But truthfully, it worked pretty well. Here's a video.

(Warning, I apologize if my bald dome blinds you, wish I wore a hat

https://drive.google.com/file/d/1FzaBvJV_1tcqxdvaZDUKwEbjhEAkPf50/view?usp=sharing

Now this still requires a good eye, and some mis-punches are still inevitable. Eventually one has to accept that the inlays won't be perfect, but at the very least, better than some of the misprints I was getting with the perforated labels. But the cuts were clean and the labels were fitting the recess perfectly. I figured this was as good as it was going to get.

So with this figured out, all that was left was labeling. Now without perferations, it takes an Xacto knife to separate the backing. Here a video on that.

https://drive.google.com/file/d/1XzONHqxGDrwNLhnczwUXaWzpSWZZtV91/view?usp=sharing

So as I mentioned in the videos I figured it was about 5 minutes to punch out a sheet of 48, or about 20 mintues to get enough labels per rack. And labelling I figured was about an hour per rack. So 80 minutes per rack times 8 racks is 640 minutes, or nearly 11 hours of hand work.

So if I had all these answers at the outset of the project and the right tools for the job this probably would have come to about $121 in materials and printing as I said above. But since I had to buy tools, pay an extra shipping charge on the labels, buy a craft punch that was basically worthless I probably have closer to $200 and the aforementioned 11 of sweat equity into this set.

Here are a few more pictures.

A word about the designs:

The Free River Club design is basically a local photo tour. And this is part of the process of which I'm most proud, but again, the credit for the pictures goes to the aforementioned Missus JustinInMN.

In my location in Dakota County in the Twin Cities area we are known as "South of the river" because we are separated from the Twin Cities proper and inner suburbs by the Minnesota River. So that and the concept of a "free river" card in poker was the inspiration for the name. The pictures are locations near the Minnesota and Mississippi rivers except for nickel which is just clip art of a walleye. (You can't do a Minnesota themed set without a Walleye. And maybe making them look at a fish is my passive aggressive way to mock my nickel chip players.)

The quarter is the Mendota Bridge (which carries MN-55 over the Minnesota River) near the confluence of the Minnesota and Mississippi Rivers and is the largest span in the Twin Cities area. It's one of my favorite bridges because of it's arches and from the top you can see both skylines. It also seemed to fit well on a yellow.

The single is Minnehaha Falls, one of the best natural attractions in the area and just north of the Mendota bridge form the quarter chip. This picture is taken from a small walking bridge near the base of the falls that crosses Minnehaha creek. I think this looks great on a blue chips. (I am very much team blue dollar, which was one of my frustrations with the black diamond set, the grey single and brown quarter were just too close in color, I like contrasting yellow and blue much better.)

The five is the Minneapolis Queen, a tour boat that docks at Bohemian Flats park in Minneapolis, somewhat between downtown and the University of Minnesota. The red paddle wheel I think made this a great choice for a red chip, along with the association of paddle wheel boats and old school gambling.

The twenty-five is the giant lawn chair at High Bridge Park in Saint Paul. The chair overlooks the Mississippi river at the foot of the High Bridge (which carries MN-149 toward downtown Saint Paul) and this seemed quite fitting for a green chip given how few green landmarks there are.

Summary:

So if you've stuck through this whole thing, I'm really proud of you. I bet you didn't think you'd be willing to read 1500 words on ABS chips. Here's the summary in case you took the shortcut.

Pros

- I think I have discovered the least expensive credible method to do custom labeled chips.

- If your players are used to ABS, this will actually be fairly impressive.

- Blue dollars! No stock sets at this price point offer blue dollars. I hate white dollars so much this must have factored among the prompts for getting me to try this in the first place.

- I love the pictures and I feel it really makes this set personal.

Warnings

- Do not expect your home printer to be accurate enough to meet the tolerances needed at this size.

- Hand punching is the only way, and even at this, it won't be perfect. (If you can't live with this, paying @Gear 30 cents a chip is probably a worthwhile alternative.)

- While the poly label material seems to work pretty well through normal use, if I take a fingernail to it like a scratch ticket, I can leave scuffs rather easily. (But again, I have spare label sheets, I can replace inlays as needed.)

- These chips have zero value other than as blanks. (On an aside, I sold the aforementioned black diamond chips to an out of town buddy of mine while visiting one of his games. I just got $40 and as I recall, I was minus 20 that night. So an example of the warnings of chips at this level not holding their value. But that said, I'm personally way more into customization than collectibility so for me personally, that's just a hazard of my taste.)

So I'm glad I went through this exercise, and I hope this set lasts a little while. I host a game every month or two only so it's probably fine for that. But I think I have the bug to get better customs down the line, probably in a year or two that will hopefully last.

To that end, in recent months on the forum, I did get a sample of the PCF Gemaco Tournament Chips that @Apache made. Also, I just ordered a sample set of ceramics from @ABC Gifts and Awards ($11 now, possibly hundreds later

https://www.pokerchipforum.com/threads/cpc-a-mold-aria-style.28820/

I already have ideas for photos for a 20 and 100, and if I ever make it up to North Branch, MN, I'll have the missus snap a picture of this for the nickel.

https://goo.gl/maps/G89NqQrsjER2

In other words, while I'm happy with the set and I'm proud I followed through on the work required, I still find myself questioning the wisdom of dumping $200 on this in the first place, now that I clearly have "the bug" and the taste for wanting to do this on better materials.

So I've answered the question on the least expensive method to do this as my contribution to the forum. I'm happy with the results, but I find myself wanting more. You decide if this contribution is brilliant, or a cautionary tale.

Last edited: