Mr. Cheese

Full House

After almost two years of owning my custom Chanman cloth I finally bit the bullet and built my custom Gangster Squad Table. Actually getting my custom CPC Gangster Squad chips was a big motivator for me to get the matching table done.

Details:

86x46 inches

5 inch rail

65 pound 1 inch foam used for rail

Whisper vinyl

Volara 2A 1/4 inch foam for playing surface

Chanman custom cloth (thanks to @T_Chan for the cloth and @p5woody for designing it for me)

Twin oak pedestals 33 inches in between

2x 3/4 inch Maple plywood used for the build

Pedestal risers built from solid hardwood. A very special thanks to @lnlver who made these for me

Finished product (I may paint the pedestal black at some point)

Without further ado pictures I took during the whole process:

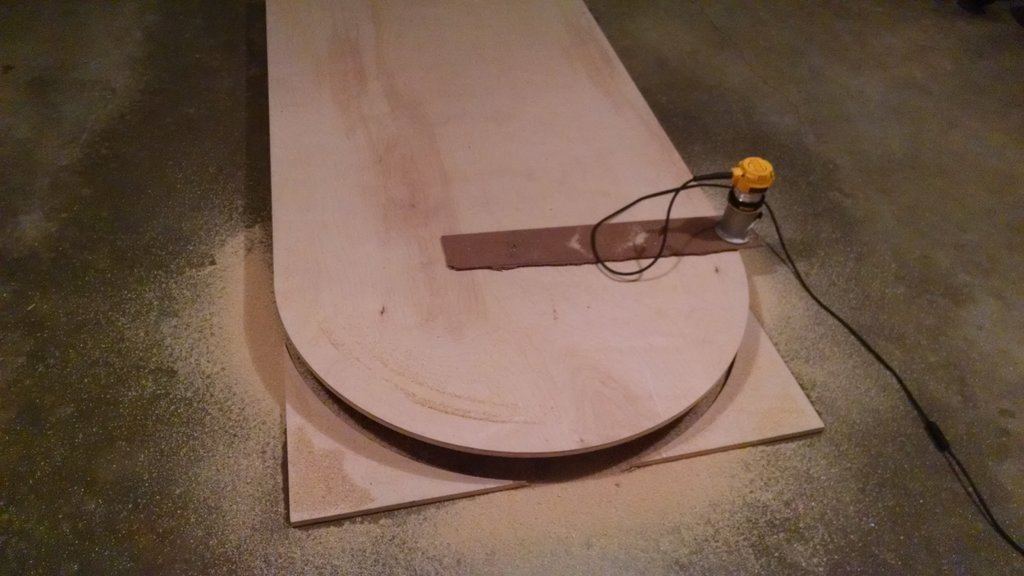

My homemade circle jig made from a scrap piece of masonite board

Rail lower locating ring (1.5 or 2 inches I believe)

Doing the 5 inch rail arcs now before removing my fancy circle jig from the router

Rail piece is finished, just awaiting a good sanding to round off the edges and smooth everything out.

lower rail locating ring final cuts

Pedestal risers made by @lnlver - They fit perfectly! Thank You!

In this picture you can see my lower support piece going between the pedestals is too short so I had to make a new one.

Gluing and screwing the rail pieces together.

Now the sanding process on all the sharp edges!

Putting the studs from the old lower pedestal support on the new longer 2x6 solid oak board.

Time to start staining everything! More shots of Bobs beautiful pedestal spacers!

Picked a shade to dark for the stain but eventually I may paint everything black so its a moot point. That or I'll sand the pedestals and restain them someday

More to come in next post

Details:

86x46 inches

5 inch rail

65 pound 1 inch foam used for rail

Whisper vinyl

Volara 2A 1/4 inch foam for playing surface

Chanman custom cloth (thanks to @T_Chan for the cloth and @p5woody for designing it for me)

Twin oak pedestals 33 inches in between

2x 3/4 inch Maple plywood used for the build

Pedestal risers built from solid hardwood. A very special thanks to @lnlver who made these for me

Finished product (I may paint the pedestal black at some point)

Without further ado pictures I took during the whole process:

My homemade circle jig made from a scrap piece of masonite board

Rail lower locating ring (1.5 or 2 inches I believe)

Doing the 5 inch rail arcs now before removing my fancy circle jig from the router

Rail piece is finished, just awaiting a good sanding to round off the edges and smooth everything out.

lower rail locating ring final cuts

Pedestal risers made by @lnlver - They fit perfectly! Thank You!

In this picture you can see my lower support piece going between the pedestals is too short so I had to make a new one.

Gluing and screwing the rail pieces together.

Now the sanding process on all the sharp edges!

Putting the studs from the old lower pedestal support on the new longer 2x6 solid oak board.

Time to start staining everything! More shots of Bobs beautiful pedestal spacers!

Picked a shade to dark for the stain but eventually I may paint everything black so its a moot point. That or I'll sand the pedestals and restain them someday

More to come in next post