Fact or fiction?

-

This site contains affiliate links. If you choose to make a purchase after clicking a link, Poker Chip Forum may receive a commission at no additional cost to you. Thank you for your support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

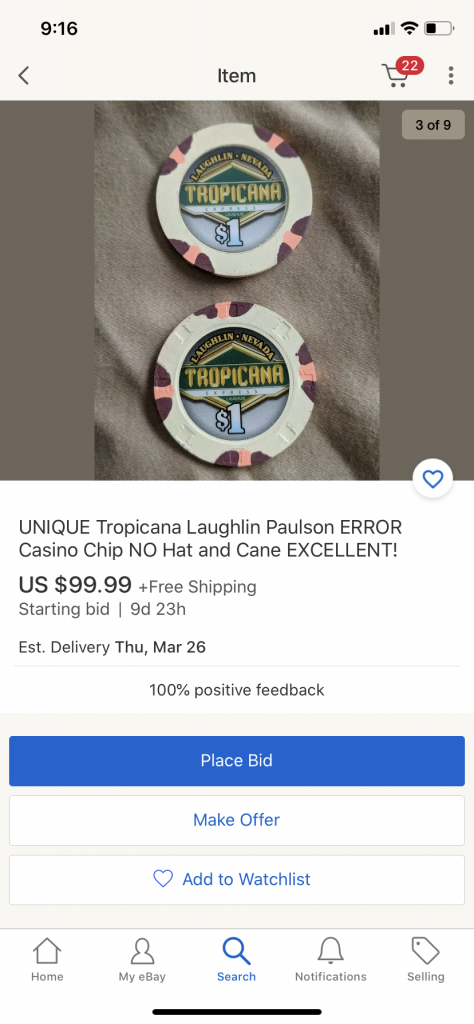

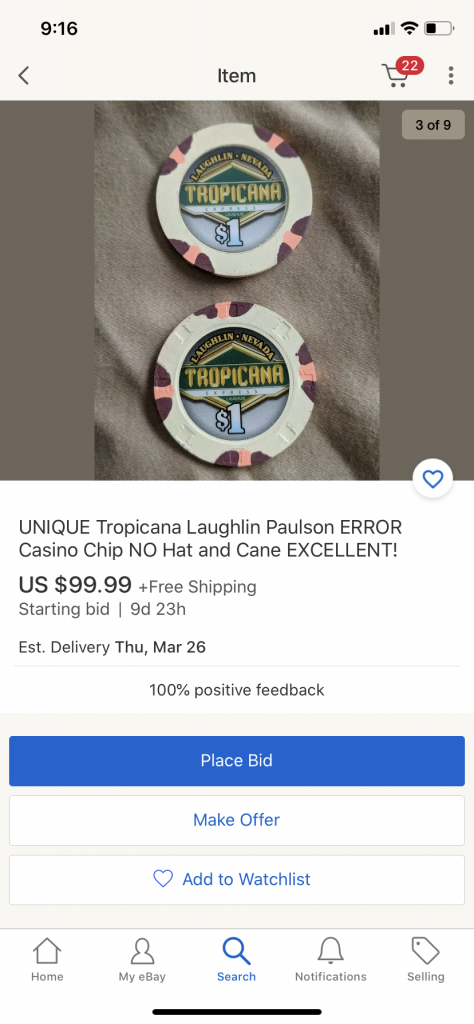

Not Mine Tropicana Laughlin $1 ERROR (1 Viewer)

- Thread starter ReallyGoodUsername

- Start date

Eloe2000

Straight Flush

I saw this pop up too. Their story on the error process jives with my understanding of the manufacturing process, just missing that last step. But I don’t see how this happens and the chip gets lumped in with other finalized chips. I would have guessed an employee swiped this from the line or the rejection pile instead of the OP story.

Last edited:

markleteenie

4 of a Kind

Get me to a belt sander and I'll get you a chip with no hats on one side.

AWenger

Full House

Watching. (but not a buyer). Is the ad from a well know chip seller on eBay? and/or maybe a member of the chipboard?

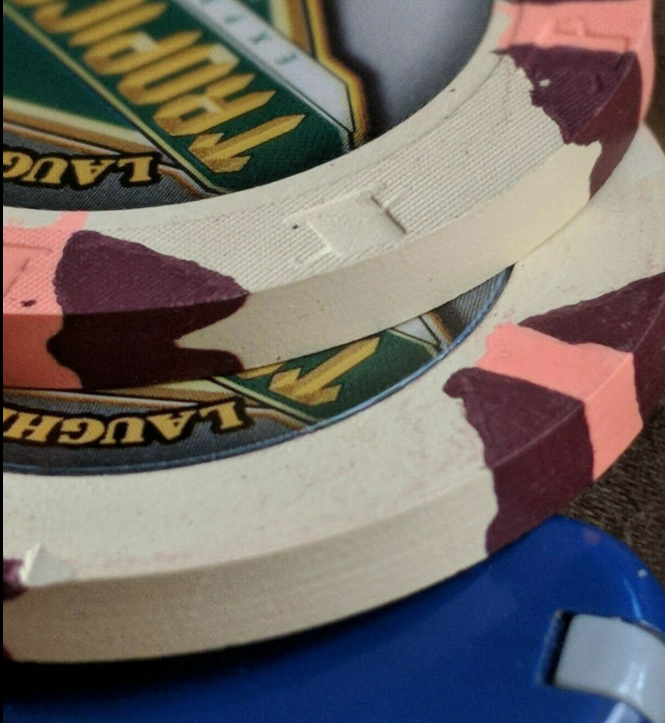

Just for info -- I own some RHC chips that are worn down to the point where the canes are hardly visible, and they fit 22 to a 66.7mm barrel. So that corresponds to around a 10% reduction in material thickness to make the hat & cane 'disappear.'

Any potential buyer might want to ask for better side-by-site photos, and/or a photo showing a caliper measurement of the chip thickness for comparison.

That's what I was thinking too. There's another photo in the ad that shows a side-by-side comparison (assuming it's not digitally altered, the chip looks close to the same width as the original), but it's hard to tell.Get me to a belt sander and I'll get you a chip with no hats on one side.

Just for info -- I own some RHC chips that are worn down to the point where the canes are hardly visible, and they fit 22 to a 66.7mm barrel. So that corresponds to around a 10% reduction in material thickness to make the hat & cane 'disappear.'

Any potential buyer might want to ask for better side-by-site photos, and/or a photo showing a caliper measurement of the chip thickness for comparison.

is it possible to wear down but still have sharp edges? I know someone here actually hired someone to “square” chips that we’re tires but they also had to trim the diameter a noticeable amount and it still wasn’t a sharp edge like this. The other confusing part is the inlay. Are some of the inlays on these particular chips larger than the rest? Like the one on the error chip?Just for info -- I own some RHC chips that are worn down to the point where the canes are hardly visible, and they fit 22 to a 66.7mm barrel. So that corresponds to around a 10% reduction in material thickness to make the hat & cane 'disappear.'

View attachment 420696

AWenger

Full House

Sure. Sanding block. Or use double-sided tape and tape a fine-medium grit sandpaper to a very flat, hard, surface, and gently slide chip from side to side for a while.is it possible to wear down but still have sharp edges?

I'm just thinking that chips aren't made like that. You're trying to tell me that a chip is pressed once, to give it its shape and sharp edges and to make it solid with its inserts, then pressed a second time to get it's hats and canes?

No.

Not to say it can't be real - I suppose it somehow could have been pressed on a plain mold, and then I'm not sure what to think about its alleged half-ass inlay.. But his explanation for how it came to be - it sounds like poop.

No.

Not to say it can't be real - I suppose it somehow could have been pressed on a plain mold, and then I'm not sure what to think about its alleged half-ass inlay.. But his explanation for how it came to be - it sounds like poop.

I have a chip that may support this actually. Looks like it was stamped twice with hat and canes. BrbI'm just thinking that chips aren't made like that. You're trying to tell me that a chip is pressed once, to give it its shape and harp edges and to make it solid with its inserts, then pressed a second time to get it's hats and canes?

No.

Not to say it can't be real - I suppose it somehow could have been pressed on a plain mold. But his explanation for how it came to be - it sounds like poop.

Eloe2000

Straight Flush

I'm just thinking that chips aren't made like that. You're trying to tell me that a chip is pressed once, to give it its shape and sharp edges and to make it solid with its inserts, then pressed a second time to get it's hats and canes?

No.

Not to say it can't be real - I suppose it somehow could have been pressed on a plain mold, and then I'm not sure what to think about its alleged half-ass inlay.. But his explanation for how it came to be - it sounds like poop.

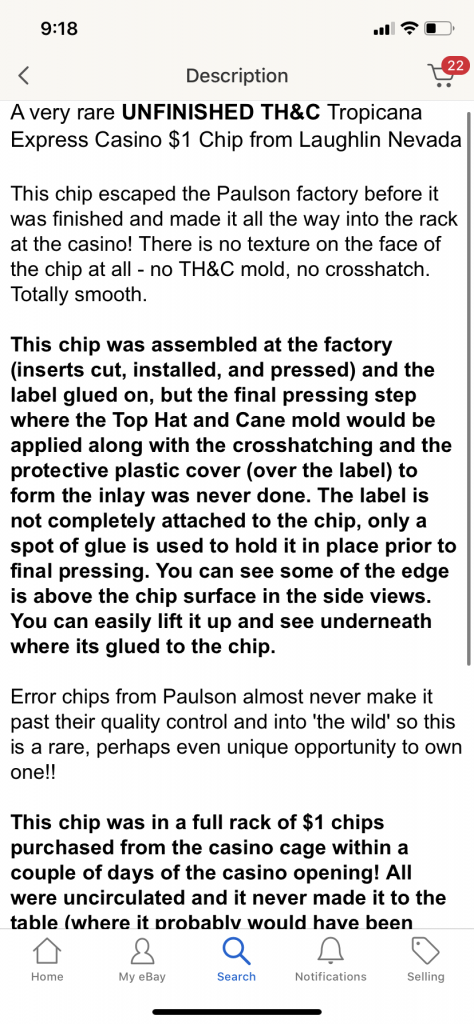

Yes, that is the way I understand it and also the way that makes logical sense to me. Also, I know I am not going to find it now but there are some illustration diagrams somewhere here on PCF either from GPI or maybe it was CPC that shows the steps of the process. 1: base blank chip is constructed and formed/molded/pressed 2: edge spots are cut out and replaced with different color clay 3) chip is pressed a second time now with indentation for inlay 4) the inlay is placed on chip 5) chip is pressed a final time to impress the inlay, add texture, add the mold.

@David Spragg could probably tell us if this was legit or not.

EDIT: I was looking around and haven't found the illustrations I was referring to, and this doesn't support my recollection, but this is pretty neat: https://www.pokerchipforum.com/thre...cturing-samples-stages-of-construction.40180/

Last edited:

Yes, that is the way I understand it and also the way that makes logical sense to me. Also, I know I am not going to find it now but there are some illustration diagrams somewhere here on PCF either from GPI or maybe it was CPC that shows the steps of the process. 1: base blank chip is constructed and formed/molded/pressed 2: edge spots are cut out and replaced with different color clay 3) chip is pressed a second time now with indentation for inlay 4) the inlay is placed on chip 5) chip is pressed a final time to impress the inlay, add texture, add the mold.

@David Spragg could probably tell us if this was legit or not.

EDIT: I was looking around and haven't found the illustrations I was referring to, and this doesn't support my recollection, but this is pretty neat: https://www.pokerchipforum.com/thre...cturing-samples-stages-of-construction.40180/

markleteenie

4 of a Kind

So with the mold/cups, is there only one on top, and the chip has to get stamped, flipped, and stamped? I don't see any other way you could get one blank and one hat/cane (other than they mismatched top and bottom cups?)

It would seem to be more efficient to have the cup on both sides, like a george foreman grill, so you only have to compress/stamp it once. Less room for error, and savings of time.

It would seem to be more efficient to have the cup on both sides, like a george foreman grill, so you only have to compress/stamp it once. Less room for error, and savings of time.

Chip is legit -- it somehow bypassed the final pressing.

Some places actually create the 'slug' (chip with spots only) using one mold, then use a different mold for the final pressing. It can sometimes cause 'ghosting', where the first mold's impressions can still be seen after the second pressing (either double images if the same mold was used, or two different mold markings if different molds were used). Using a blank mold for the initial pressing eliminates the potential ghosting issue.

That's exactly how they are made, although the 'sharp edges' are machined or ground to size/shape after the second pressing. The first pressing is to create a 'slug' with the edge spots added. The inlays are then added, and it is pressed a second time to add the final mold markings and secure the inlay.I'm just thinking that chips aren't made like that. You're trying to tell me that a chip is pressed once, to give it its shape and sharp edges and to make it solid with its inserts, then pressed a second time to get it's hats and canes?

Molds have two cups, one for each side of the chip. The chip on eBay is smooth on both sides.So with the mold/cups, is there only one on top, and the chip has to get stamped, flipped, and stamped? I don't see any other way you could get one blank and one hat/cane (other than they mismatched top and bottom cups?)

It would seem to be more efficient to have the cup on both sides, like a george foreman grill, so you only have to compress/stamp it once. Less room for error, and savings of time.

Some places actually create the 'slug' (chip with spots only) using one mold, then use a different mold for the final pressing. It can sometimes cause 'ghosting', where the first mold's impressions can still be seen after the second pressing (either double images if the same mold was used, or two different mold markings if different molds were used). Using a blank mold for the initial pressing eliminates the potential ghosting issue.

Only error in the listing is regarding the inlay -- it was glued on for the second pressing, then skipped that step and went straight to edge finishing. The inlay was not on the chip during the first pressing (or it wouldn't be loose).

markleteenie

4 of a Kind

Oh I see, I misread it and thought it was smooth on one side and hat and cane on the other. That makes more sense now.The chip on eBay is smooth on both sides.

Similar threads

- Replies

- 4

- Views

- 396

- Replies

- 1

- Views

- 158

- Locked

- Replies

- 22

- Views

- 1K

- Replies

- 4

- Views

- 347