Jeff in Iowa

Pair

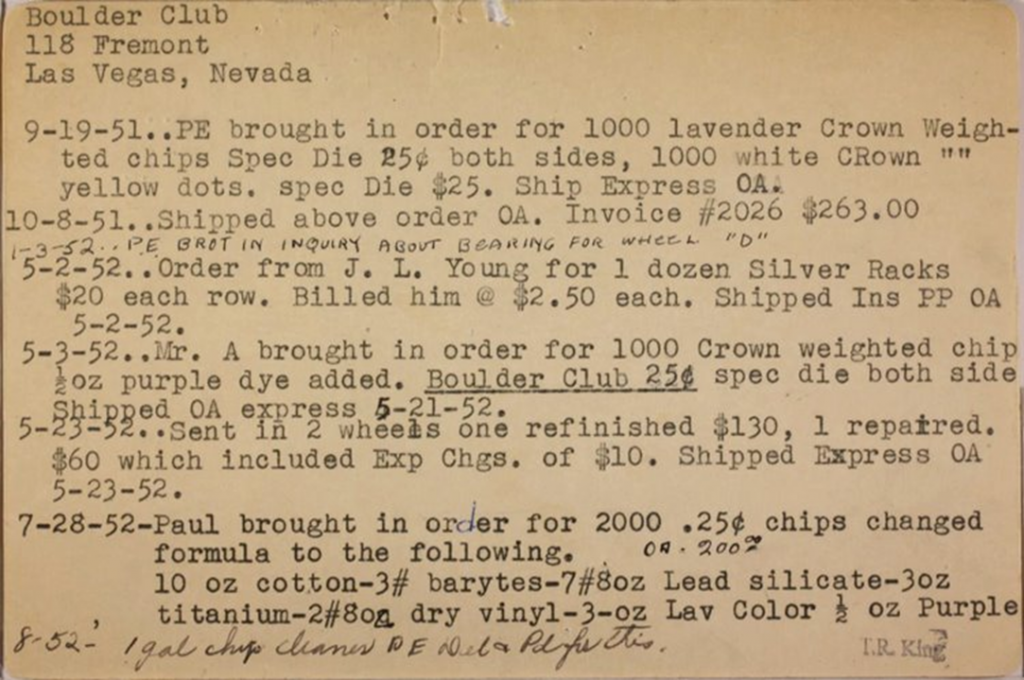

I thought some people might find this interesting. Somewhat recently hundreds of TRK chip order cards from the 1940s until the 1980s were posted onto the ChipGuide. I've been looking through those cards and noticed that that one of the cards lists their chip formula, for at least one color, Lavender. (See the bottom of the card.) Titanium was the surprise ingredient for me. By weight, there seems to be even more of it than even lead.

(10 ox cotton #3, barytes-7#8oz, Lead silicate-30oz, titanium-2#80, dry vinyl-3-oz, Lav Color, ½ oz Purple)

http://chipguide.themogh.org/cg_showpic2.php?cg=218407

(10 ox cotton #3, barytes-7#8oz, Lead silicate-30oz, titanium-2#80, dry vinyl-3-oz, Lav Color, ½ oz Purple)

http://chipguide.themogh.org/cg_showpic2.php?cg=218407