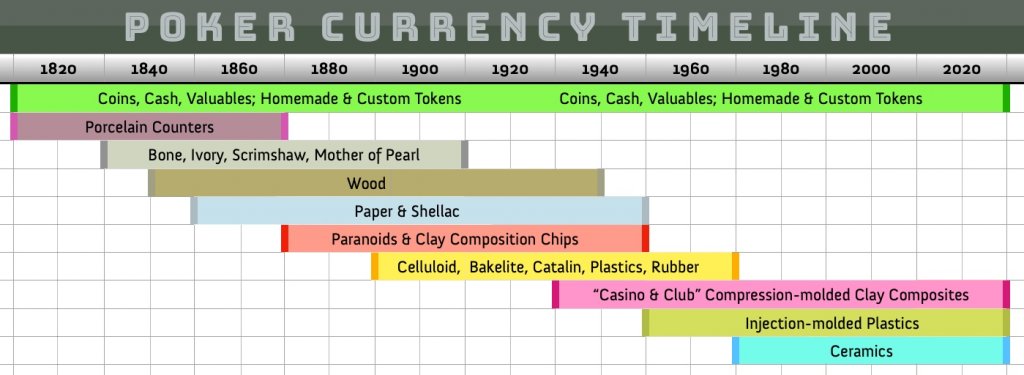

For a writing project, I went hunting around the interwebs for a simple timeline of what materials were used for poker chips across the roughly two-century history of the game. I was surprised not to find such a timeline (though it is quite possible my google skillz failed me).

Below is my first *totally provisional, off-the-cuff, totally spitballed attempt* at a timeline. I am throwing this out there not as anything even remotely authoritative, but as a conversation starter. I may be completely off on some/all items, and probably I have forgotten some type of chip which should be mentioned. Note that I focused only on checks/tokens/other placeholders for currency used in poker games.

I’m not trying to go back farther in to the history of gambling pre-poker. I am really not sure when some of the early materials (various forms of bone and wood) started to disappear, but I suspect it was by 1930 or so, as modern materials started to take over the markets. I also haven't included various novelty/bespoke materials. (For example, if you go on Etsy or other sites you can find people making chips out of various metals and other impractical materials.)

Anyway, here is the starter chart I made in a spreadsheet program:

Here is an updated (v2) based on the comments so far in this thread. Please see the caveats later in the discussion... This is still very provisional and needs editing/suggestions/corrections.

Below is my first *totally provisional, off-the-cuff, totally spitballed attempt* at a timeline. I am throwing this out there not as anything even remotely authoritative, but as a conversation starter. I may be completely off on some/all items, and probably I have forgotten some type of chip which should be mentioned. Note that I focused only on checks/tokens/other placeholders for currency used in poker games.

I’m not trying to go back farther in to the history of gambling pre-poker. I am really not sure when some of the early materials (various forms of bone and wood) started to disappear, but I suspect it was by 1930 or so, as modern materials started to take over the markets. I also haven't included various novelty/bespoke materials. (For example, if you go on Etsy or other sites you can find people making chips out of various metals and other impractical materials.)

Anyway, here is the starter chart I made in a spreadsheet program:

Here is an updated (v2) based on the comments so far in this thread. Please see the caveats later in the discussion... This is still very provisional and needs editing/suggestions/corrections.

Last edited: