I’ve been moderately successful at my inlay removal process. I do however end up with an uneven surface where the inlay once was. Will this be OK once I get my labels, or do I have to “smooth” this surface somehow. Thanks!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Surface prep prior to Labeling (1 Viewer)

- Thread starter JayBob

- Start date

It probably depends on the labels and the surface (not helpful, I know) but if you’re using gear laminated labels. I wouldn’t worry about it at all - they’re nice and thick and the glue is strong.

My only experience labeling a whole rack by myself, I used @Gear non-laminated labels directly on top of very worn hot stamps. This is not recommended because hot stamps make a very uneven surface. These were so worn though that they were mostly smooth and I figured I could get away with it. And I did. The labels adhered perfectly and never failed. Since they were the thin, non-laminated labels, sometimes when the light hit the chips right you could make out some of the imperfections under the labels. But the takeaway here is that even with thin labels on unprepped surfaces, the result was still a 9 out of 10.

Edit: let me just add that I’m not recommending anybody do what it did, but maybe it’s useful information.

And back to prep, if you have any surface where edges of gauges rise above the rest of the surface, I’d definitely scratch those down. But minor gauges themselves are probably fine.

My only experience labeling a whole rack by myself, I used @Gear non-laminated labels directly on top of very worn hot stamps. This is not recommended because hot stamps make a very uneven surface. These were so worn though that they were mostly smooth and I figured I could get away with it. And I did. The labels adhered perfectly and never failed. Since they were the thin, non-laminated labels, sometimes when the light hit the chips right you could make out some of the imperfections under the labels. But the takeaway here is that even with thin labels on unprepped surfaces, the result was still a 9 out of 10.

Edit: let me just add that I’m not recommending anybody do what it did, but maybe it’s useful information.

And back to prep, if you have any surface where edges of gauges rise above the rest of the surface, I’d definitely scratch those down. But minor gauges themselves are probably fine.

Last edited:

What you're replacing with is probably not a lot thicker than what you removed, so you should be good to go. At least it's not going to be worse than what it was originally.

Charichard

Pair

I’m in the middle of relabeling chips as well. The natural uneven surface is fine as long as you aren’t applying a ton of pressure when applying the labels. The only time I need to smooth the chip is on those accidental deep cuts made during the inlay removal process that produce a little ridge of clay. As long as the area feels smooth on your thumb then it should be ready to relabel. I had to accept that there will be small flaws with some of the chips during the process for my sanity though. YMMV. GL!

I'm about 4 months in the back of the line for Gear Labels for my Paris Cash Set. But I've "practiced" on a sample set of Bally's already (my fracs to be) and even though the inlay removal process isn't too difficult at all, I'll have to stare at the imperfections for 4 months before I can fix them...I think I'll need therapy to get me through.

AlbinoDragon

Flush

Having only done over-labels I might not be able to provide specific help here, but I can say making sure the receiving surface is clean helps a bunch. I de-labeled several before adding new ones and almost imperceptible little pieces of residue make a very obvious bump in the label.

OfficerLovejoy

Full House

Let us share the pain and post some pictures.I'm about 4 months in the back of the line for Gear Labels for my Paris Cash Set. But I've "practiced" on a sample set of Bally's already (my fracs to be) and even though the inlay removal process isn't too difficult at all, I'll have to stare at the imperfections for 4 months before I can fix them...I think I'll need therapy to get me through.

Maybe we can give some advice on better cutting techniques if yours leaves huge craters.

merkong

Flush

I have some labels I’ll be removing soon and am going to look for an exacto blade that is configured more for “scraping”; like the blade is maybe “squared off” and the sharp portion is on the end. It seems to me that if they make such a blade it’ll minimize the gouging.

I have some labels I’ll be removing soon and am going to look for an exacto blade that is configured more for “scraping”; like the blade is maybe “squared off” and the sharp portion is on the end. It seems to me that if they make such a blade it’ll minimize the gouging.

Just use a small box cutter blade. It's cheap and has the flexibility you need.

I have some labels I’ll be removing soon and am going to look for an exacto blade that is configured more for “scraping”; like the blade is maybe “squared off” and the sharp portion is on the end. It seems to me that if they make such a blade it’ll minimize the gouging.

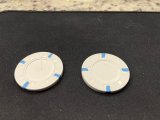

You mean something like this? This is an X-Acto #17 blade.

Attachments

Similar threads

- Replies

- 3

- Views

- 360