Briefly: solids and those on ends of rolls seem most brittle, crumble in the packaging and are easily broken in half with the slightest application of force. I'm speaking about spirit molds, but this seems to apply to a couple other China clay mold styles as well.

I recently bought some grey spirit molds, as part of a larger purchase, with full knowledge of the brittleness issue - the seller was completely up front on the issue.

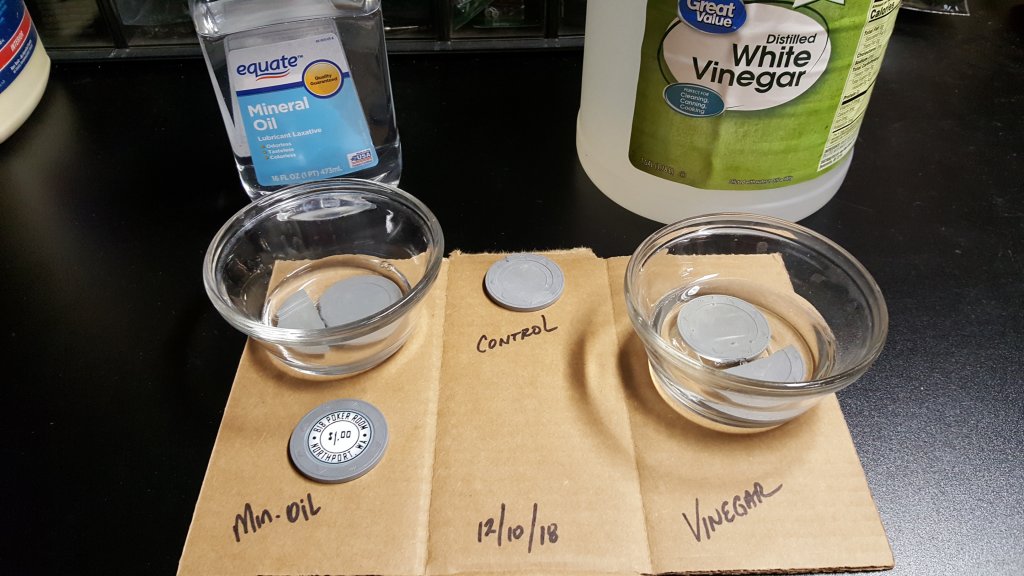

Assuming the brittleness is the result of the material drying out: I am going to see if I can, over the course of three weeks, restore some resiliency to the chips by:

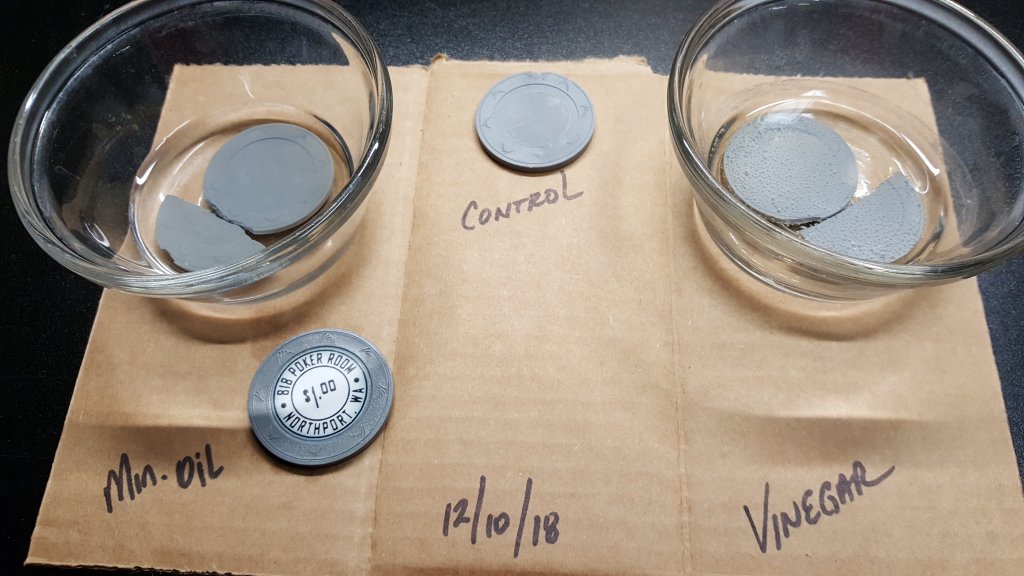

12/17/2018 Update:

Observations at end of first week:

No visual change to the chip soaking in mineral oil. There feels to be a layer of sludge on the chip, though nothing visible. The half-chip broke easily with slight pressure.

Bubbles could be seen clinging to the chip surface in the vinegar dish. The chip feels the same as it did the day it went into this bath. The half-chip broke easily, though it withstood slightly more pressure than the oil soaked chip.

The labeled chip feels normal & looks good. I'm not yet ready to see how easily it breaks - maybe next Monday.

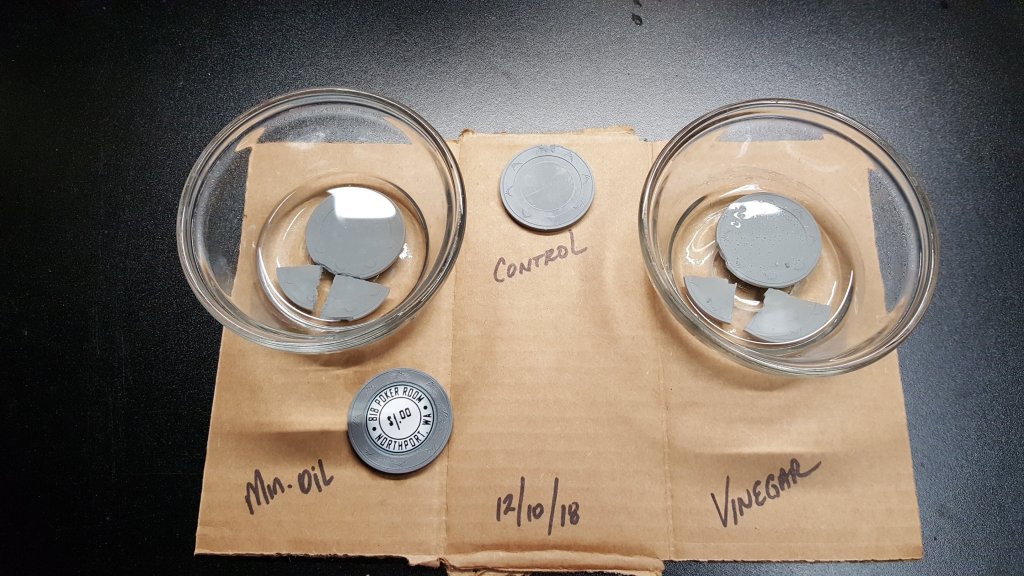

I dropped the labeled chip several times onto the workbench surface (laminated particle board) from a height of about 5 inches and there was [edit] no [edit] breakage or chipping.

I may end this exercise next Monday as my attention span is not what it once was.

Image taken 12/17/18:

Image taken 12/17/18 (after breakage testing):

So far I'm thinking:

There may be such thing as too much oil,

There is some level of alkali in the chip material and it reacts to/with the vinegar. This is advantageous when working with actual clay - but may provide little or no benefit regarding poker chip "clay", China or otherwise.

I was encouraged by the labeled and oiled chip not breaking or chipping with minimal abuse, and look forward to seeing how much the label bolsters its integrity at the end of this highly unscientific experiment.

Definitely ending this next Monday (y) :thumbsup:

I recently bought some grey spirit molds, as part of a larger purchase, with full knowledge of the brittleness issue - the seller was completely up front on the issue.

Assuming the brittleness is the result of the material drying out: I am going to see if I can, over the course of three weeks, restore some resiliency to the chips by:

- soaking one and half chips in mineral oil.

- soaking one and half chips in vinegar, and

- lightly oiling a labeled chip once per week

12/17/2018 Update:

Observations at end of first week:

No visual change to the chip soaking in mineral oil. There feels to be a layer of sludge on the chip, though nothing visible. The half-chip broke easily with slight pressure.

Bubbles could be seen clinging to the chip surface in the vinegar dish. The chip feels the same as it did the day it went into this bath. The half-chip broke easily, though it withstood slightly more pressure than the oil soaked chip.

The labeled chip feels normal & looks good. I'm not yet ready to see how easily it breaks - maybe next Monday.

I dropped the labeled chip several times onto the workbench surface (laminated particle board) from a height of about 5 inches and there was [edit] no [edit] breakage or chipping.

I may end this exercise next Monday as my attention span is not what it once was.

Image taken 12/17/18:

Image taken 12/17/18 (after breakage testing):

So far I'm thinking:

There may be such thing as too much oil,

There is some level of alkali in the chip material and it reacts to/with the vinegar. This is advantageous when working with actual clay - but may provide little or no benefit regarding poker chip "clay", China or otherwise.

I was encouraged by the labeled and oiled chip not breaking or chipping with minimal abuse, and look forward to seeing how much the label bolsters its integrity at the end of this highly unscientific experiment.

Definitely ending this next Monday (y) :thumbsup:

Last edited: