Nex

Flush

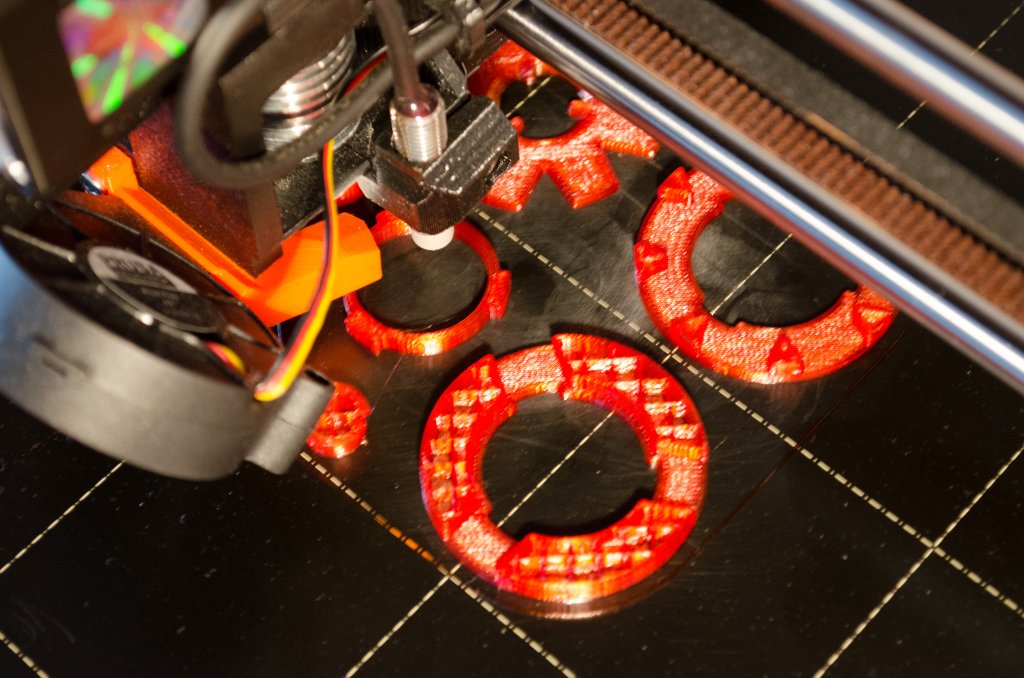

Wasted about 80 grams of material and a lot of time with misprints - mainly due to incomplete part design changes, but some also due to piss poor material behavior of a new premium price spool I was using (thanks PrimaSelect)...

I'm just too lazy to build Inventor assemblies for all the possible combinations to preview how the parts fit together. However, doing that didn't stop me from doing such misprints for the very first combination I built either, so duh. Waste seems inevitable in R&D no matter how good your simulation possibilities are.

Arbitrary diameter modifications to all parts are complete now. I can print all the eight parts a complete punch consists of for any cookie diameter I want now (okay, there is a certain minimum and maximum diameter for technical reasons, but you get it). It still would be a lot of dull work to add the necessary new entries to the configuration tables, but no actual modifications to the part designs are needed to make it work. Just copypasting and editing a lot of stuff in a spreadsheet.

I am now done with the round punch designs for Moon, HC, W and V spots.

Printed a single 43mm punch of each spot style for starters.

Picked up a couple more filament spools and have enough colors now to give each spot style's pushout assembly a different color for easier recognition:

Moon: Blue transparent

HC: Green transparent

W: Yellow transparent

V: Red transparent

34: White

58: Lavender

916: Blue

12: Green

38: Yellow

14: Orange

18: Red

I have cut down on the round punch variations, removing any combination punch, i.e. these punches will not cut D(S)/T(S) multi-color spots in one go. I have opted for a two-punch approach to reduce design complexity / number of punch variations. Plus, this gets it closer to what happens with actual chip punching anyway I believe. If you want to create a 3TA14 cookie for example, you would use a 334 round punch first to get the cookie bodies, and then use a dedicated 14 spot punch to get the spots. There will not be a round punch that cuts the three 14 spots individually out of the cookie body. I will however make variations of the dedicated spot punches that will cut multiple spots of the same type in one go.

There won't be a dedicated spot punch for W style spots as these can be assembled with two V and one 18 spot.

I also had an improvement idea for the mold assembly design. Two optimizations: mold plate will be printable without supports and handle pin will get a broader plate. It takes quite some force to press the dough into the desired form and the thin pin in the center concentrated all the resistance forces on one small spot in your palm which does get painful after pressing the mold onto a couple of cookies. With a broader handle, the force should get distributed better. Also, as a side effect, the modification to make the mold plate printable without supports will increase the rigidity of the mold plate, so it should imprint more evenly over the whole surface.

This mold modification idea only exists as a bunch of doodles on paper currently. I will first finish up all the variations for the punches (7 more to go, each requiring changes to three parts) before building the modifications in Inventor.

After that, I will make the dedicated spot punches. I have come to the conclusion that due to the size and shape of these it won't be feasible to make them a three-part assembly with punch, top clip and pushout. I am going to drop the top clip; the pushout piece will be loose inside the punch.

I am also going to make 43mm versions of the THC-LCV/SCV and RHC molds. There won't be a 39mm version for IHC though.

I'm just too lazy to build Inventor assemblies for all the possible combinations to preview how the parts fit together. However, doing that didn't stop me from doing such misprints for the very first combination I built either, so duh. Waste seems inevitable in R&D no matter how good your simulation possibilities are.

Arbitrary diameter modifications to all parts are complete now. I can print all the eight parts a complete punch consists of for any cookie diameter I want now (okay, there is a certain minimum and maximum diameter for technical reasons, but you get it). It still would be a lot of dull work to add the necessary new entries to the configuration tables, but no actual modifications to the part designs are needed to make it work. Just copypasting and editing a lot of stuff in a spreadsheet.

I am now done with the round punch designs for Moon, HC, W and V spots.

Printed a single 43mm punch of each spot style for starters.

Picked up a couple more filament spools and have enough colors now to give each spot style's pushout assembly a different color for easier recognition:

Moon: Blue transparent

HC: Green transparent

W: Yellow transparent

V: Red transparent

34: White

58: Lavender

916: Blue

12: Green

38: Yellow

14: Orange

18: Red

I have cut down on the round punch variations, removing any combination punch, i.e. these punches will not cut D(S)/T(S) multi-color spots in one go. I have opted for a two-punch approach to reduce design complexity / number of punch variations. Plus, this gets it closer to what happens with actual chip punching anyway I believe. If you want to create a 3TA14 cookie for example, you would use a 334 round punch first to get the cookie bodies, and then use a dedicated 14 spot punch to get the spots. There will not be a round punch that cuts the three 14 spots individually out of the cookie body. I will however make variations of the dedicated spot punches that will cut multiple spots of the same type in one go.

There won't be a dedicated spot punch for W style spots as these can be assembled with two V and one 18 spot.

I also had an improvement idea for the mold assembly design. Two optimizations: mold plate will be printable without supports and handle pin will get a broader plate. It takes quite some force to press the dough into the desired form and the thin pin in the center concentrated all the resistance forces on one small spot in your palm which does get painful after pressing the mold onto a couple of cookies. With a broader handle, the force should get distributed better. Also, as a side effect, the modification to make the mold plate printable without supports will increase the rigidity of the mold plate, so it should imprint more evenly over the whole surface.

This mold modification idea only exists as a bunch of doodles on paper currently. I will first finish up all the variations for the punches (7 more to go, each requiring changes to three parts) before building the modifications in Inventor.

After that, I will make the dedicated spot punches. I have come to the conclusion that due to the size and shape of these it won't be feasible to make them a three-part assembly with punch, top clip and pushout. I am going to drop the top clip; the pushout piece will be loose inside the punch.

I am also going to make 43mm versions of the THC-LCV/SCV and RHC molds. There won't be a 39mm version for IHC though.

Last edited: