Nex

Flush

I already recently mentioned this over in the CPC Tri-Moon punch thread, but now I have a first picture that warrants creating a thread. I will update it as I make progress. This will be fairly slow, so don't expect updates every day.

-----

Sometime mid to end of January, a Prusa i3 MK3 3D printer kit will be arriving here.

Of course the real fun in 3D printing is not just stupidly downloading and printing finished designs other people have made, but actually designing your own stuff. Aside from a few other things, this has been something I wanted to do since I read about David trying 3D printed clay punches to test new spot designs: Cookie cutters.

Using food coloring on some standard butter cookie recipe made with white flour, I presumed it should be fairly easy to get very decent-looking results, provided I have the necessary tools - and I'm going to design and print them. Using PETG for printing as it is food-safe and, as a nice side effect, also said to be sturdier than PLA.

I am starting with a Paulson-style 3Moon cutter as a proof of concept. If it works well, I'll probably make a couple more spot designs, possibly also more intricate ones.

To minimize the amount of waste/need to re-roll dough, I will make separate cookie cutters just for a set of edge spots that will be arranged close to each other.

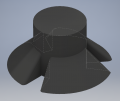

There will also be a "mold" tool to imprint something on one side of the cookie after it has been assembled (and cut off any excess dough in the same step). Here I will start by cloning Paulson's THC mold as close as possible. Later on I can also make different mold designs, and I will have to if I want to either publish or sell these.

The cutters will mostly consist of four parts:

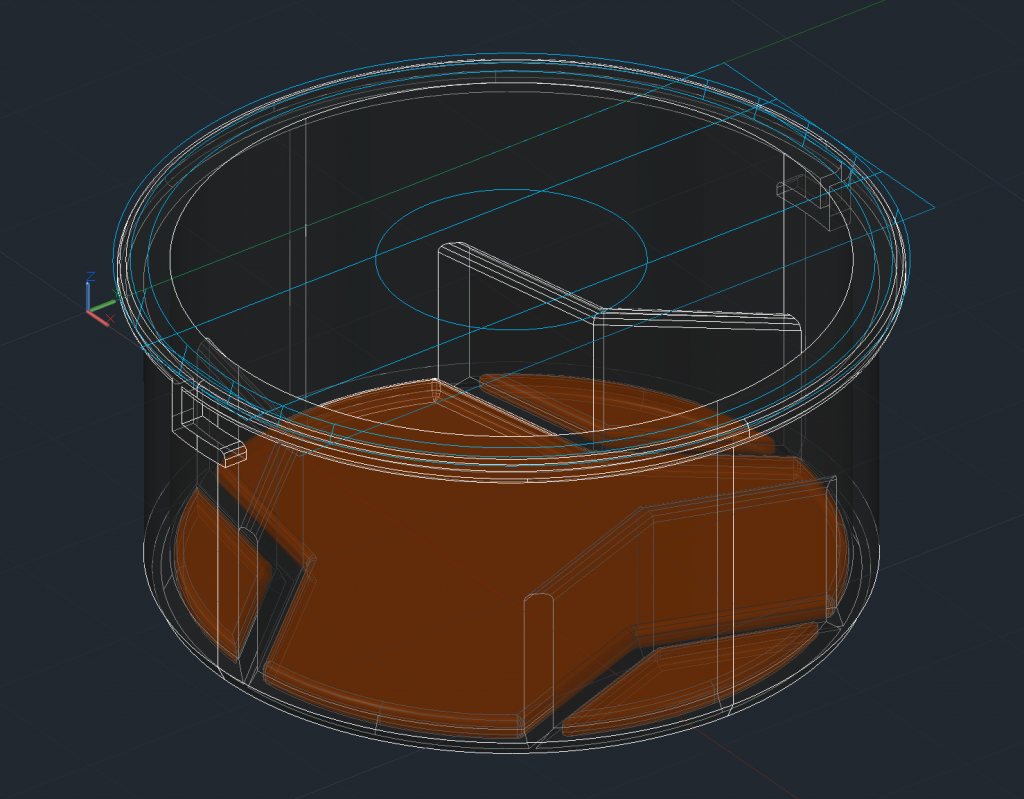

In the drawing below, you can already see the round punch and the bottom parts of all the pushouts. The blue lines at the top are my draft for the top clip. You can already see the circle for the hole where the pin from the chip body pushout is supposed to go through.

-----

Sometime mid to end of January, a Prusa i3 MK3 3D printer kit will be arriving here.

Of course the real fun in 3D printing is not just stupidly downloading and printing finished designs other people have made, but actually designing your own stuff. Aside from a few other things, this has been something I wanted to do since I read about David trying 3D printed clay punches to test new spot designs: Cookie cutters.

Using food coloring on some standard butter cookie recipe made with white flour, I presumed it should be fairly easy to get very decent-looking results, provided I have the necessary tools - and I'm going to design and print them. Using PETG for printing as it is food-safe and, as a nice side effect, also said to be sturdier than PLA.

I am starting with a Paulson-style 3Moon cutter as a proof of concept. If it works well, I'll probably make a couple more spot designs, possibly also more intricate ones.

To minimize the amount of waste/need to re-roll dough, I will make separate cookie cutters just for a set of edge spots that will be arranged close to each other.

There will also be a "mold" tool to imprint something on one side of the cookie after it has been assembled (and cut off any excess dough in the same step). Here I will start by cloning Paulson's THC mold as close as possible. Later on I can also make different mold designs, and I will have to if I want to either publish or sell these.

The cutters will mostly consist of four parts:

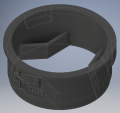

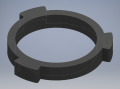

- The round punch to cut the chip circle from the dough, which also integrates the cutting parts for the spots on the inside.

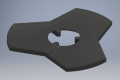

- A pushout piece for the chip body without the spots. This one will have a pin in the center that goes upwards and protrudes a little over the top end of the round punch.

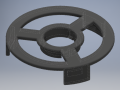

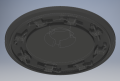

- A single pushout piece for all the spots. This one will have a hole in the centerpiece where the pin from the chip body pushout fits through. Both pushouts are supposed to be possible to operate independently.

- A clip for the top of the round punch, which will act as guiding support for the two pushouts.

In the drawing below, you can already see the round punch and the bottom parts of all the pushouts. The blue lines at the top are my draft for the top clip. You can already see the circle for the hole where the pin from the chip body pushout is supposed to go through.

Last edited: