GenghisKhan

Full House

- Joined

- Nov 7, 2014

- Messages

- 2,897

- Reaction score

- 4,696

Hi everyone,

So all the millers always say just remove enough material to put the label. And that it's ok if you still see some of the old stamp.

That being said, do you prefer a label that is flush with the chip or slightly recessed?

Reason for asking at the bottom.

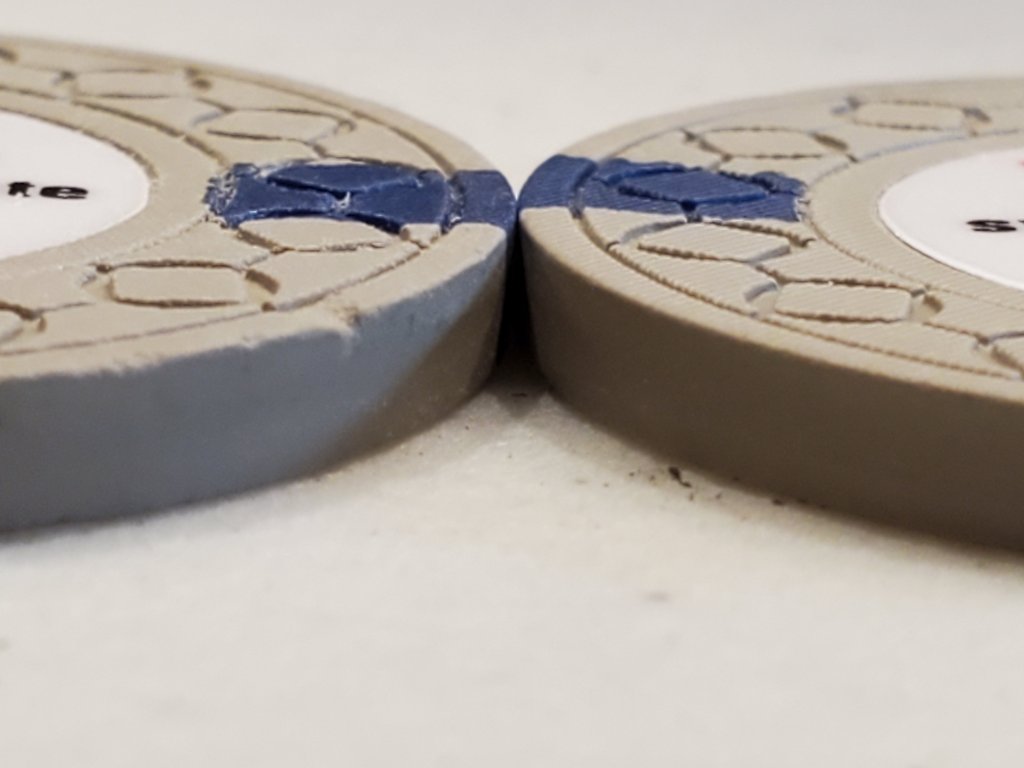

Left = slight recess

Right = flush with surface

These stamps go deeper than on the previous 800 chips I milled and I'm worried that will show through the balel. I can still feel the grooves of the stamp.

@Josh Kifer @Eloe2000 ?

So all the millers always say just remove enough material to put the label. And that it's ok if you still see some of the old stamp.

That being said, do you prefer a label that is flush with the chip or slightly recessed?

Reason for asking at the bottom.

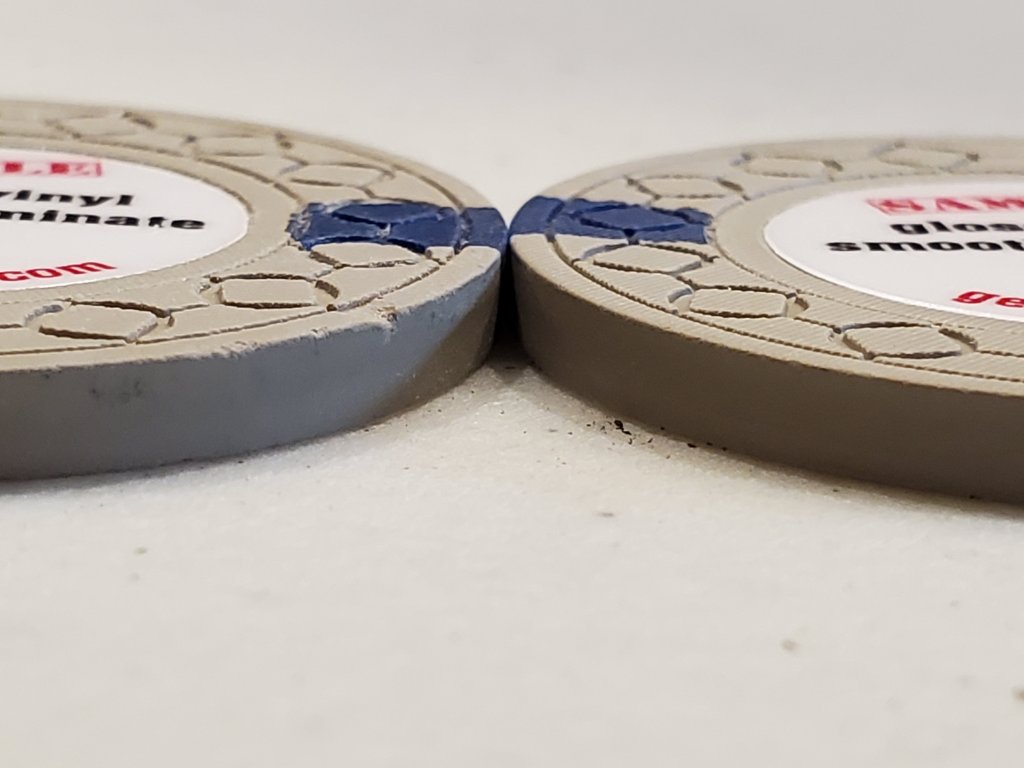

Left = slight recess

Right = flush with surface

These stamps go deeper than on the previous 800 chips I milled and I'm worried that will show through the balel. I can still feel the grooves of the stamp.

@Josh Kifer @Eloe2000 ?