Ha, thanks! I expect this to take several iterations to get it right. But once I do, I should be able to interlock 5 together to build a vertical 47mm rack for my champ chips. Slow but steady ... I'll post back when I have something that isn't laughableLooking nice!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Matsui Racks...why? (1 Viewer)

- Thread starter mnebesny

- Start date

After a bunch of test prints and some trial and error, I think I have the tolerations of my printer nailed down. I've got the right sizing for the tube, and I've got the interconnecting cleat working. I think I'm ready to actually try printing two full size barrel holders and connect them together.

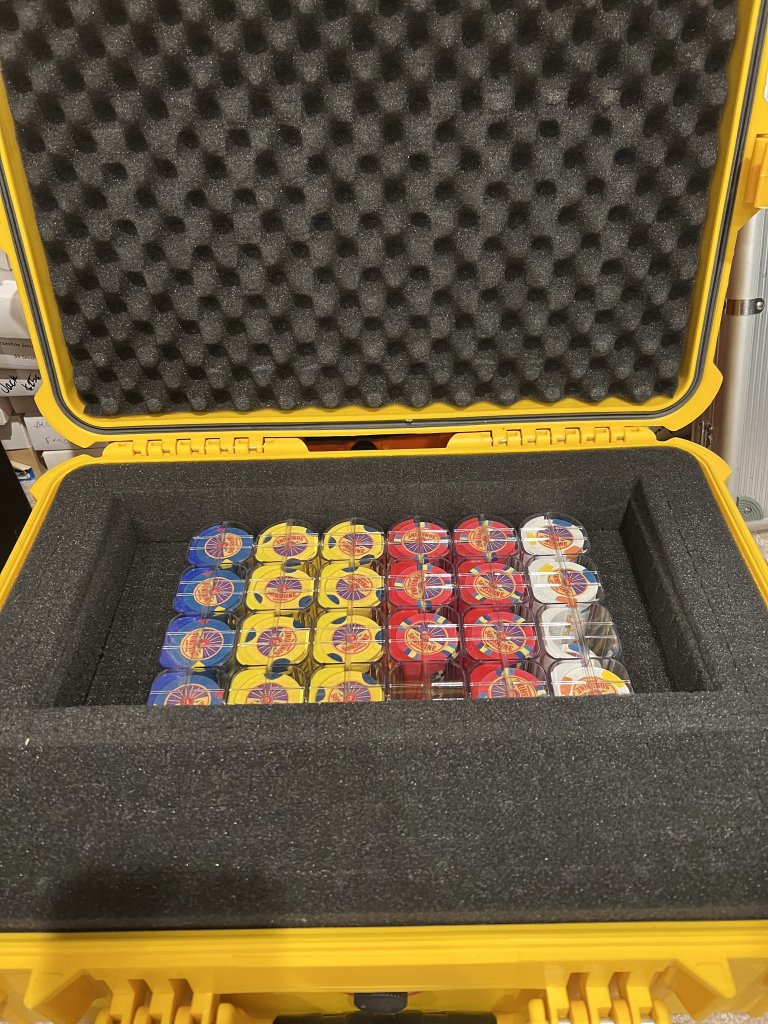

One thing that did occur to me is that if I don't have enough chips to fill the entire barrel, they're going to move around when they're inside of my Apache pelican-style case. In other words, the foam doesn't touch them to hold them in. That could be a reason that vertical storage is less desirable perhaps? Anyone have any ideas on how to solve this problem?

One thing that did occur to me is that if I don't have enough chips to fill the entire barrel, they're going to move around when they're inside of my Apache pelican-style case. In other words, the foam doesn't touch them to hold them in. That could be a reason that vertical storage is less desirable perhaps? Anyone have any ideas on how to solve this problem?

Last edited:

Moar chips!After a bunch of test prints and some trial and error, I think I have the tolerations of my printer nailed down. I've got the right sizing for the tube, and I've got the interconnecting cleat working. I think I'm ready to actually try printing two full size barrel holders and connect them together.

View attachment 669218

One thing that did occur to me is that if I don't have enough chips to fill the entire barrel, they're going to move around when they're inside of my Apache case. In other words, the foam doesn't touch them to hold them in. That could be a reason that vertical storage is less desirable perhaps? Anyone have any ideas on how to solve this problem?

ekricket

Royal Flush

That’s cool. Since you are making attached barrels can you try a variant and make them 12 chips high for starting stack racks? A breakdown might be 12/12/5/6/1 which lends itself to 3 interlocked tubes if they hold 12 each. Load them up, pass them out, and players can either remove the chips or gently turn the whole thing over to get their starting stack.After a bunch of test prints and some trial and error, I think I have the tolerations of my printer nailed down. I've got the right sizing for the tube, and I've got the interconnecting cleat working. I think I'm ready to actually try printing two full size barrel holders and connect them together.

View attachment 669218

One thing that did occur to me is that if I don't have enough chips to fill the entire barrel, they're going to move around when they're inside of my Apache pelican-style case. In other words, the foam doesn't touch them to hold them in. That could be a reason that vertical storage is less desirable perhaps? Anyone have any ideas on how to solve this problem?

Yeah, I sure can! Once I get a working model, adjusting the height is trivial. The first use of this concept will be to provide storage for my 47mm ceramic champ/member chips. The second use will be for 60mm DB storage. I'm debating how tight I want the barrels to fit together. I can have it so that I have to tap them together with a mallet b/c the fit is so tight. This will provide me with a solid rack, but will limit my versatility since I won't be able to easily separate them for any reason in the future. Then again, 100 DBs is going to be awfully heavy, so maybe I want to be able to separate them.That’s cool. Since you are making attached barrels can you try a variant and make them 12 chips high for starting stack racks? A breakdown might be 12/12/5/6/1 which lends itself to 3 interlocked tubes if they hold 12 each. Load them up, pass them out, and players can either remove the chips or gently turn the whole thing over to get their starting stack.

I can make them looser fit, but then that goes against the idea of providing starting stacks for people. I guess I can do both; I can make the cleat tighter for starting stacks and make it 1mm looser for 47mm+ chips in order to prevent 100lb racks

One Eyed Dollar

Flush

I like the progress so far, @BearMetal!

@ekricket messaged me about doing something like this earlier, and I've been kicking ideas around in my head for a few weeks. I'm still in the early stages, but I thought I'd share my ideas in case you want to incorporate any of them in your design and run with it.

I was thinking about a honeycomb design with hexagons to make the racks narrower, because offset circles fit closer together than aligned circles. I also wanted them to interlock with cleats (or magnets would be cool, but not as strong and more complicated to print) for flexibility of how many you want to connect together. I also thought about making one size for the external dimensions but making a version with a hole for 39mm chips and one for 43mm chips. That way they could still lock together, but you wouldn't have to put 39mm chips in 43mm holes and have them rattle around. This might be handy for sets with 43mm upper denoms and 39mm lower denoms.

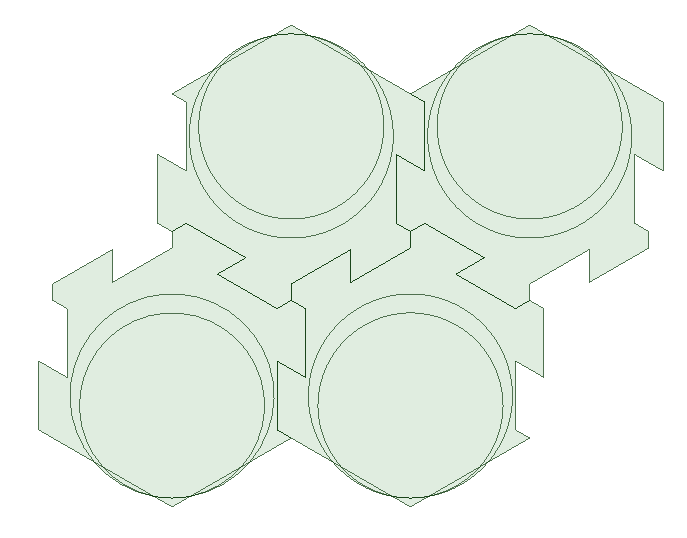

Anyway, here's a sketch of this idea:

Kind of ugly and still needs refinement, but you can see where it's going.

Other thoughts:

@ekricket messaged me about doing something like this earlier, and I've been kicking ideas around in my head for a few weeks. I'm still in the early stages, but I thought I'd share my ideas in case you want to incorporate any of them in your design and run with it.

I was thinking about a honeycomb design with hexagons to make the racks narrower, because offset circles fit closer together than aligned circles. I also wanted them to interlock with cleats (or magnets would be cool, but not as strong and more complicated to print) for flexibility of how many you want to connect together. I also thought about making one size for the external dimensions but making a version with a hole for 39mm chips and one for 43mm chips. That way they could still lock together, but you wouldn't have to put 39mm chips in 43mm holes and have them rattle around. This might be handy for sets with 43mm upper denoms and 39mm lower denoms.

Anyway, here's a sketch of this idea:

Kind of ugly and still needs refinement, but you can see where it's going.

Other thoughts:

- I was going to cut out the lip underneath the chips to make it easier to grab them and lift them out.

- Have you played with the diameter of the hole to see what works best for getting the chips in and out without allowing too much slop?

I'm still in the early stages, but I thought I'd share my ideas in case you want to incorporate any of them in your design and run with it.

Very cool idea! I'm really bad when it comes to anything artistic. Photoshop, Gimp, Inkscape, CAD ... I mean, I'm kinda amazed I got this far! So, I think that interlocking hexagons might be out of the scope of my abilities. I also don't know if my printer's tolerances are fine enough to get a good, snug fit with so many connection points. The reason I went with a cleat was to try to prevent the variance of my printer from causing problems at touch points.I was thinking about a honeycomb design with hexagons to make the racks narrower, because offset circles fit closer together than aligned circles

One thing that irked me a little was the total width b/c of the thickness of the cylinder wall. It definitely makes the entire rack longer since it's 5mm x 10 just for the shell wall. But, again, I plant to store these in a pelican, and I believe I can fit 5 the short way.

Yeah, I'm going to do the same. I'm just going to vary the center cutout to make different sizes for different chips. I plan on 60mm DB, 47mm member chips, and 43/39mm starting racks.I also thought about making one size for the external dimensions but making a version with a hole for 39mm chips and one for 43mm chips. That way they could still lock together,

I actually did! I have very fat fingers and ceramic chips are a little slippery on the edge. So, I made my cutout 19mm so my index finger could easily get in there and lift them all out. I thought I'd have trouble getting the bottom one out, but I'm able to get under it and the whole barrel lifts out!Have you played with the diameter of the hole to see what works best for getting the chips in and out without allowing too much slop?

Apparently I'm too stupid to read my calipers, so the first barrel came out short. Second a barrel came out the perfect size for 20. The interlocking is perfect, it's tight but I can remove them if I want to. At 3.5 hours per barrel, I might be able to get one rack done in about a day and a half.

Still not sure I like the thickness of the bottom. It's 7 mm which I thought would be necessary for the weight, but it's possible I can strip it down to 5 mm.

Still not sure I like the thickness of the bottom. It's 7 mm which I thought would be necessary for the weight, but it's possible I can strip it down to 5 mm.

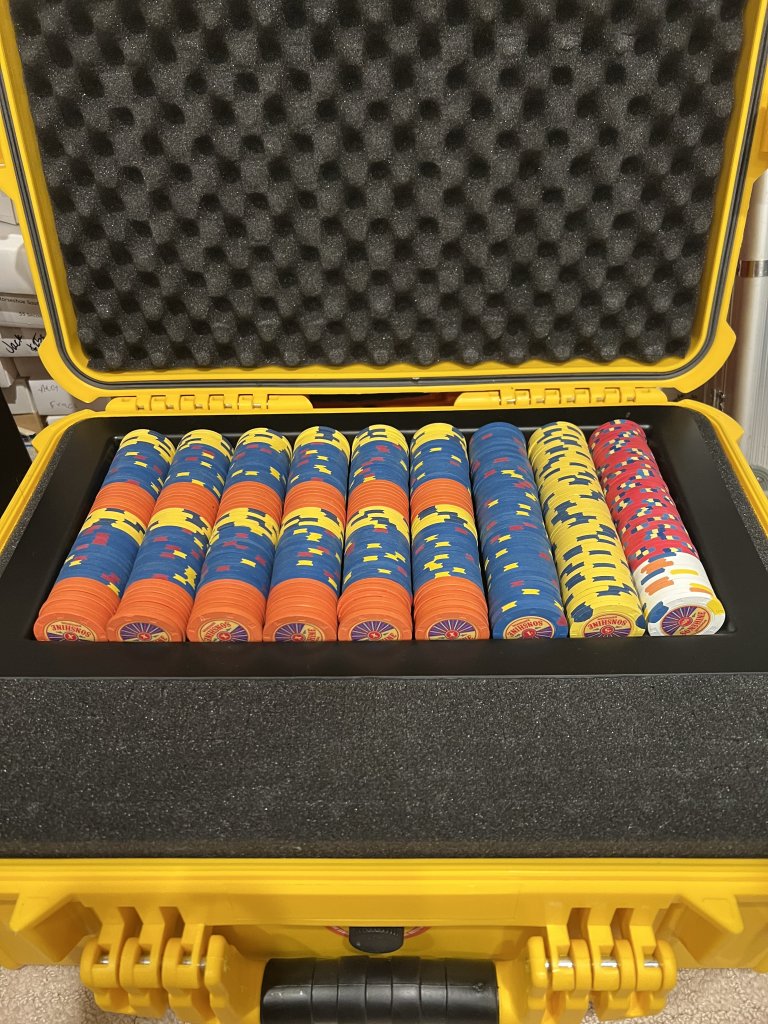

I'm officially calling this a success! They stay together really well, they come apart relatively easily if I wanted them to, and they fit the 47 mm chips perfectly. What's next... Dealer buttons!!!!!!

I stopped at 4 for now since my daughter says, "the 3D printer is for rainbow frogs, not poker chips"

I stopped at 4 for now since my daughter says, "the 3D printer is for rainbow frogs, not poker chips"

ekricket

Royal Flush

Really really nice!I'm officially calling this a success! They stay together really well, they come apart relatively easily if I wanted them to, and they fit the 47 mm chips perfectly. What's next... Dealer buttons!!!!!!

View attachment 670612

View attachment 670613

I stopped at 4 for now since my daughter says, "the 3D printer is for rainbow frogs, not poker chips"

Thanks! And thanks for the idea of trying vertical racks! If anyone wanted the STL file, just ask, I'm happy to upload it somewhere.Really really nice!

If anyone wants to make their own, I've uploaded my STL file:

https://github.com/jonathan-hurley/...models/60mm-dealer-button-vertical-barrel.stl

https://github.com/jonathan-hurley/...models/60mm-dealer-button-vertical-barrel.stl

lib

High Hand

If anyone wants to make their own, I've uploaded my STL file:

https://github.com/jonathan-hurley/...models/60mm-dealer-button-vertical-barrel.stl

Thanks for the STL!

Feel free to post a picture after you've printed them!Thanks for the STL!

I actually was thinking about this the other day when I was looking at my chips (all of which are in matsui racks) - are chips more susceptible to warping if they are stored together loosely as opposed to in tight fitting racks?39mm (and 43mm) are pretty loose; nowhere near as tight as my Chipcos ... but that doesn't cause warping...

I use matsui racks with 3d3p spacers because I have to lay the rack on its side so it need to be enclosed. And I have a tray on top To display the chips

Isn't warping caused by environmental conditions, such as humidity? If so then I would say that tightly packed chips are less susceptible to warping because less of them is exposed to the air.I actually was thinking about this the other day when I was looking at my chips (all of which are in matsui racks) - are chips more susceptible to warping if they are stored together loosely as opposed to in tight fitting racks?

ekricket

Royal Flush

Like when you leave the cracker package open and the next tree or four crackers get humidified but the rest are ok.Isn't warping caused by environmental conditions, such as humidity? If so then I would say that tightly packed chips are less susceptible to warping because less of them is exposed to the air.

ekricket

Royal Flush

But bread is the opposite, if you leave it open the first few slices get dehydrated and stale.Like when you leave the cracker package open and the next tree or four crackers get humidified but the rest are ok.

What’s going on here???!??!

divedivedive

Sitting Out

I know this is an older thread, and maybe I'm dating myself by mentioning this, but I was told not to store chips horizontally for the same reason you should never store vinyl records horizontally. Gravity can actually warp them in scalloped or concave shape.

Granted, this is much less likely to affect poker chips than vinyl due to materials and size differences. But it's a big reason I've never considered storing them this way... I have no personal experience to prove this happens with chips specifically, but some old curmudgeons from my local poker room claim to have seen it happen.

Granted, this is much less likely to affect poker chips than vinyl due to materials and size differences. But it's a big reason I've never considered storing them this way... I have no personal experience to prove this happens with chips specifically, but some old curmudgeons from my local poker room claim to have seen it happen.

Now u guys have me all freaked out about warping, etc. I just bought some sample spacers from @One Eyed Dollar to try and figure this out…… it’s always something with this hobby…

Similar threads

- Replies

- 5

- Views

- 399

- Replies

- 3

- Views

- 337