Ben8257

Royal Flush

So this one is different, figured I would make a thread.

So I bought the Forty Grand HHLs and absolutely love them... unfortunately 17 of the chips had the Inlays popping out of them. Obviously could have pulled the inlays and replaced them but wanted to keep them.original to keep the same texture. So where to go from here??

I thought maybe take a tiny exacto knife and raise them.up and slide some Glue under them and press them back in, but as soon as I tried it the inlay popped out. No suprise with the amount of glue I found behind them

So I scraped the glue off and cleaned the chips up but now I still had a bunch of curled up inlays. I decided to heat and press them

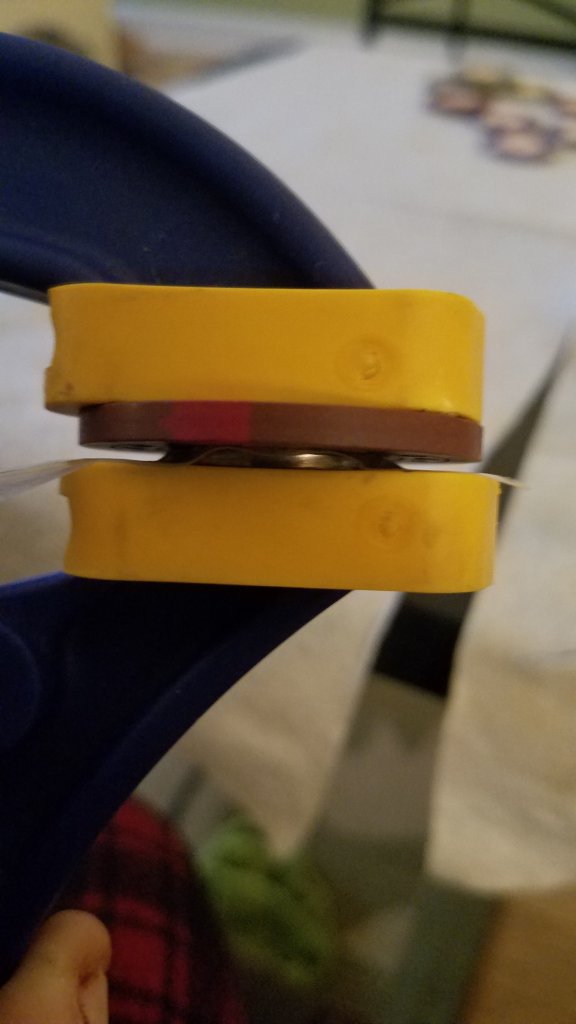

Went with chip spacers as they are flat and I could make sure the inlay was centered with them.being clear. Did 8 minutes in the oven on 170 deg, let them.sit for an hour, checked them and decided to go with a second round of heat. They weren't perfect but much better.

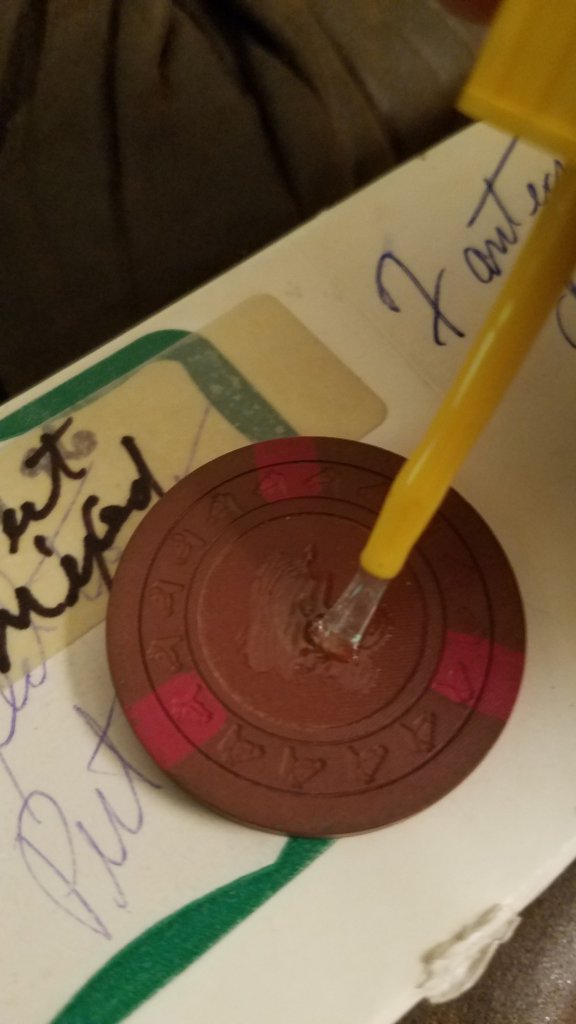

I found some Gorilla super glue that hash a brush in the bottle which was perfect to help make sure I didn't use too much glue, obviously that would come out from behind the inlay and make a mess, but also wanted to make sure it was on the edges to help keep that Inlay in the chip foe years to come.

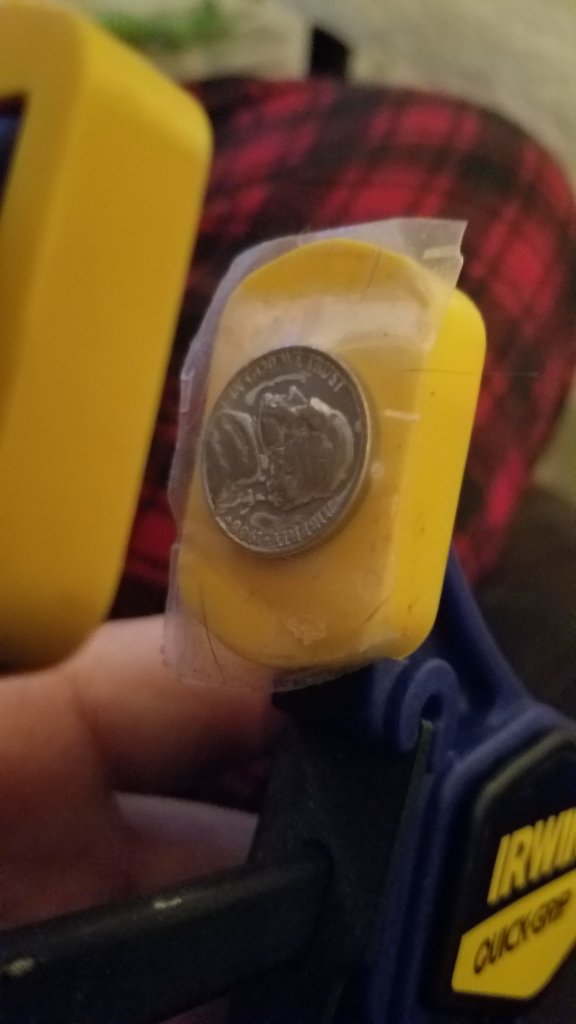

Now I wanted to press and hold the inlay in place while the glue dried. I found a nickle to be 13/16" which is perfect for a 7/8" inlay... did some professional engineering! Lmao I tape the nickle inside of a clamp as so

After gluing and pushing the inlays back in by hand I clamped them for about 5 minutes each

And now they are all fixed! Maybe should have cleaned them.forst but wanted to make sure I could save them first

Totally happy with them now, never seen a thread like this before so Ithought I would share in case someone else has chips like this.

Fellow Chipper Ben

So I bought the Forty Grand HHLs and absolutely love them... unfortunately 17 of the chips had the Inlays popping out of them. Obviously could have pulled the inlays and replaced them but wanted to keep them.original to keep the same texture. So where to go from here??

I thought maybe take a tiny exacto knife and raise them.up and slide some Glue under them and press them back in, but as soon as I tried it the inlay popped out. No suprise with the amount of glue I found behind them

So I scraped the glue off and cleaned the chips up but now I still had a bunch of curled up inlays. I decided to heat and press them

Went with chip spacers as they are flat and I could make sure the inlay was centered with them.being clear. Did 8 minutes in the oven on 170 deg, let them.sit for an hour, checked them and decided to go with a second round of heat. They weren't perfect but much better.

I found some Gorilla super glue that hash a brush in the bottle which was perfect to help make sure I didn't use too much glue, obviously that would come out from behind the inlay and make a mess, but also wanted to make sure it was on the edges to help keep that Inlay in the chip foe years to come.

Now I wanted to press and hold the inlay in place while the glue dried. I found a nickle to be 13/16" which is perfect for a 7/8" inlay... did some professional engineering! Lmao I tape the nickle inside of a clamp as so

After gluing and pushing the inlays back in by hand I clamped them for about 5 minutes each

And now they are all fixed! Maybe should have cleaned them.forst but wanted to make sure I could save them first

Totally happy with them now, never seen a thread like this before so Ithought I would share in case someone else has chips like this.

Fellow Chipper Ben