horseshoez

4 of a Kind

Alright, gathered the pics I did towards the finish line and sharing what I’ve learned.

1) First and foremost, whatever this yellow shit is, it’s a nightmare. I almost feel like something containing a yellow dye was directly above where these chips were stored and it leaked all over them. It’s some of the most stubborn stuff I’ve ever seen.

2) Once the ultrasonic process is done and they’re racked, you may want to consider leaving them as is without piling and here’s why. Given that the ultrasonic didn’t remove 100% of the film from the chips, edge oiling them or even fully oiling the chips will result in smear. It’s still there and it’s being agitated by the mineral oil enough to come off on the towel you’re using then rubbed into another part of the chip. It’s seriously a stubborn bitch to say the least. One advantage is that the chip regains its luster, giving it more depth in its color. I can honestly say that the best way to get every chip to a near perfect pink is one by one. Talk about a lengthy f’ing process. That’s not including yellow all over your hands and a ton of micro fiber towels in the trash. Not exactly fun times.

3) If I had more of these chips to use as guinea pigs, I’d be tempted to use something stronger and more aggressive than TSP. Not exactly sure what but something that ultimately does the job of stripping away a layer of paint or even a tiny layer of what you’re working with, in this case the chips. Call me crazy, but if I had any extras I may have even experimented with some GoofOff or Goo-Gone. If that doesn’t take off the yellow stuff, then forget it.

4) Magic Eraser near disaster. I tried taking the Magic Eraser to the edge of one barrel as a test to see if I can get them really really clean on the edges. Bad idea. The magic eraser also grabs whatever yellow film is there on any of the chips and smears it right across the entire barrel edge. Had to re-clean those to get it off. Stay away from Magic Eraser unless planning on doing one chip at a time and plenty of rinsing in between.

Here’s some pics,

Pre-ultrasonic

During (TSP + Dawn)

Removed from ultrasonic prior to drying

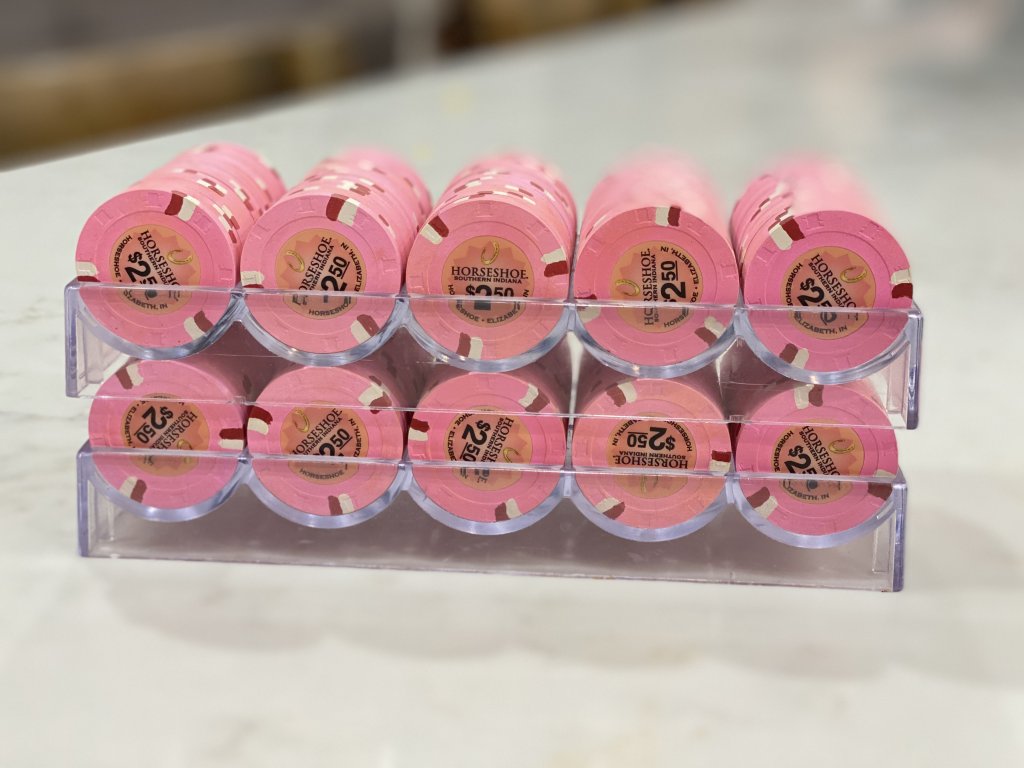

Racked prior to any oiling

Oiling one chip at a time. Still plenty of yellow film coming off

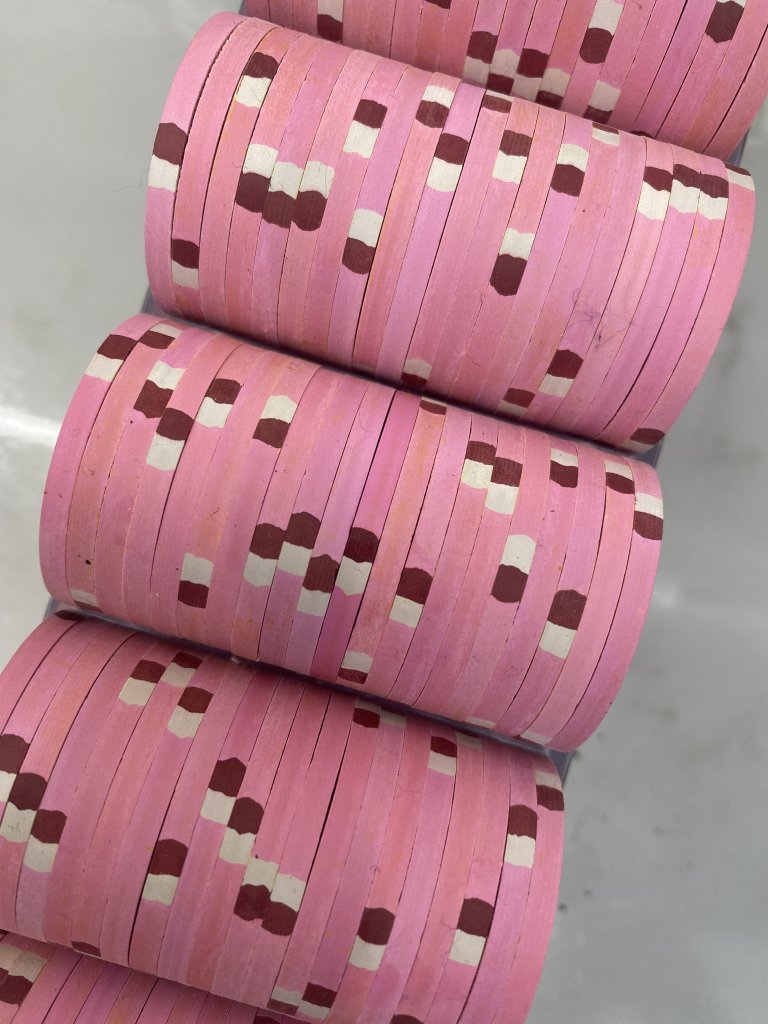

Notice the very thin yellow line of film on the edge ever after 8 minutes of being in the ultrasonic

You can easily spot the oiled chip among the others

Oiled barrel vs non

Oiled rack vs non

Both racks oiled right after rinsing under hot water while scrubbing with a dish washing sponge and Bar Keeper's Friend, trying to avoid smearing the film. Excess oil wiped off gently.

Bit of a perfectionist when it comes to cleaning and I can honestly say that I would have liked a better result but I can't complain considering how they looked before.

If I have any updates or try something else down the road that provides better results, I'll let you guys know.

1) First and foremost, whatever this yellow shit is, it’s a nightmare. I almost feel like something containing a yellow dye was directly above where these chips were stored and it leaked all over them. It’s some of the most stubborn stuff I’ve ever seen.

2) Once the ultrasonic process is done and they’re racked, you may want to consider leaving them as is without piling and here’s why. Given that the ultrasonic didn’t remove 100% of the film from the chips, edge oiling them or even fully oiling the chips will result in smear. It’s still there and it’s being agitated by the mineral oil enough to come off on the towel you’re using then rubbed into another part of the chip. It’s seriously a stubborn bitch to say the least. One advantage is that the chip regains its luster, giving it more depth in its color. I can honestly say that the best way to get every chip to a near perfect pink is one by one. Talk about a lengthy f’ing process. That’s not including yellow all over your hands and a ton of micro fiber towels in the trash. Not exactly fun times.

3) If I had more of these chips to use as guinea pigs, I’d be tempted to use something stronger and more aggressive than TSP. Not exactly sure what but something that ultimately does the job of stripping away a layer of paint or even a tiny layer of what you’re working with, in this case the chips. Call me crazy, but if I had any extras I may have even experimented with some GoofOff or Goo-Gone. If that doesn’t take off the yellow stuff, then forget it.

4) Magic Eraser near disaster. I tried taking the Magic Eraser to the edge of one barrel as a test to see if I can get them really really clean on the edges. Bad idea. The magic eraser also grabs whatever yellow film is there on any of the chips and smears it right across the entire barrel edge. Had to re-clean those to get it off. Stay away from Magic Eraser unless planning on doing one chip at a time and plenty of rinsing in between.

Here’s some pics,

Pre-ultrasonic

During (TSP + Dawn)

Removed from ultrasonic prior to drying

Racked prior to any oiling

Oiling one chip at a time. Still plenty of yellow film coming off

Notice the very thin yellow line of film on the edge ever after 8 minutes of being in the ultrasonic

You can easily spot the oiled chip among the others

Oiled barrel vs non

Oiled rack vs non

Both racks oiled right after rinsing under hot water while scrubbing with a dish washing sponge and Bar Keeper's Friend, trying to avoid smearing the film. Excess oil wiped off gently.

Bit of a perfectionist when it comes to cleaning and I can honestly say that I would have liked a better result but I can't complain considering how they looked before.

If I have any updates or try something else down the road that provides better results, I'll let you guys know.