Hey all,

Just thought I'd chime in with a bit of an update (that'll probably be a bit of a ramble!!)

First off, I owe a huge apology to Courage for the delay in stamping and a huge thanks for his patience in waiting for chips that still haven't been done.

I also offer an apology to all who emailed or PM'd without getting a response.

Personal Side

I've gone through a fairly large upheaval in my personal life that started in October (right as I went on a 2 week trip to China...yeah timing!!!) that has now finally (mostly) resolved itself.

During that time my focus was on my work and my children and at the end of most days I was thoroughly exhausted...not enough energy or thought to respond to messages let alone actually do any stamping...oddly enough, stamping may have helped as I find it quite therapeutic for the most part.

My job is rather demanding in both time and brainpower and stamping has always been only a hobby and a way for me to help the community...there really is no way to make money stamping at the rates that the market will bear...I would guess to make a "profit" you would need to be in the $0.50/chip range.

I enjoy the process of stamping (when I have the time!) and I truly enjoy being involved in the design process as well as being able to help someone get the chips they want.

Technical Side

My first machine was a manual stamper...Kingsley M-101...you can get them on

eBay for around $500. I bought it on a total lark...(may have been drinking and ebaying) and had no idea what I was doing with it. I warn anyone who buys a manual stamper...it really is an art that you have to practice...and when each chip costs $1+ it can be pricey to learn.

The physical act of stamping consists of three main elements...heat, pressure and dwell time (the amount of time the die is in contact with the chip). All three vary a bit by manufacturer, colour and mold. With a manual machine you can set the temperature but the only control you have on pressure and dwell time is how consistent you can be with your arm and brain...and over a couple of hundred chips your elbow aches and your mind wanders.

Another component is chip placement before the die strikes it...a couple of things come into play here...initial placement of the die on the machine (affects where the stamp sits in relation to the chip)...this step drives me crazy and takes the most amount of time. The other thing is the orientation of the spots in relation to the stamp...I like them all to be the same...this takes more time as you have to look at the spot and place at the same reference mark every time.

The final step is scraping the chip. I am a HUGE believer in this...I would rather stamp a little deep and get flash (the excess material that is displaced) then stamp shallow and not get as crisp of a stamp. Scraping is tedious...you take a razor blade and manually remove the flash from every chip. I've got a scar or two from this step...took me awhile to realize if I wrapped my middle finger in tape I'd avoid the slicing.

There are some stampers that don't think you need to scrape...stamp light and move on...my thoughts are that we'll see how the stamps look after a couple years of use.

My current setup is a Kingsley AM-101, a digital, pneumatic machine and one of the last models Kingsley made. $1700 plus an air compressor. This machine allows me to set temperature, pressure and dwell time. Upside to this...once you dial in the machine your consistency is great and you don't get as tired...the mind still wanders though and the machine doesn't really recognize a difference between a chip and your finger (the first and only time I ever got myself it hurt like hell for 2 weeks...thought I was going to lose a nail!!).

Chips and Stamp-ability

ASM - all good - very consistent

BCC - all good - very consistent

China Clay - no frigging way - they shatter like a dinner plate

TRK - not possible - this was a terribly sad realization for me and led me to selling my King's Crown set...I'm not sure if it the age of the chip or the surface but I could just not get anything consistent...I went through close to a rack of chips (blanks I had) trying to get the Overland's done for LabMonkey...I tried every combination of temperature, dwell time and pressure.

Paulson - no issues - I don't like doing the chips that were milled out though...the small ridge around the edge can cause problems

Current Status

Now that life (outside of work) has settled a bit I will be getting back to stamping...with the first set being for Courage.

I will always be open with the fact that if you want me to stamp your chips it will take a long time but you will be more than happy with the finished product.

I am in Canada but have a US shipping address for convenience.

Costs

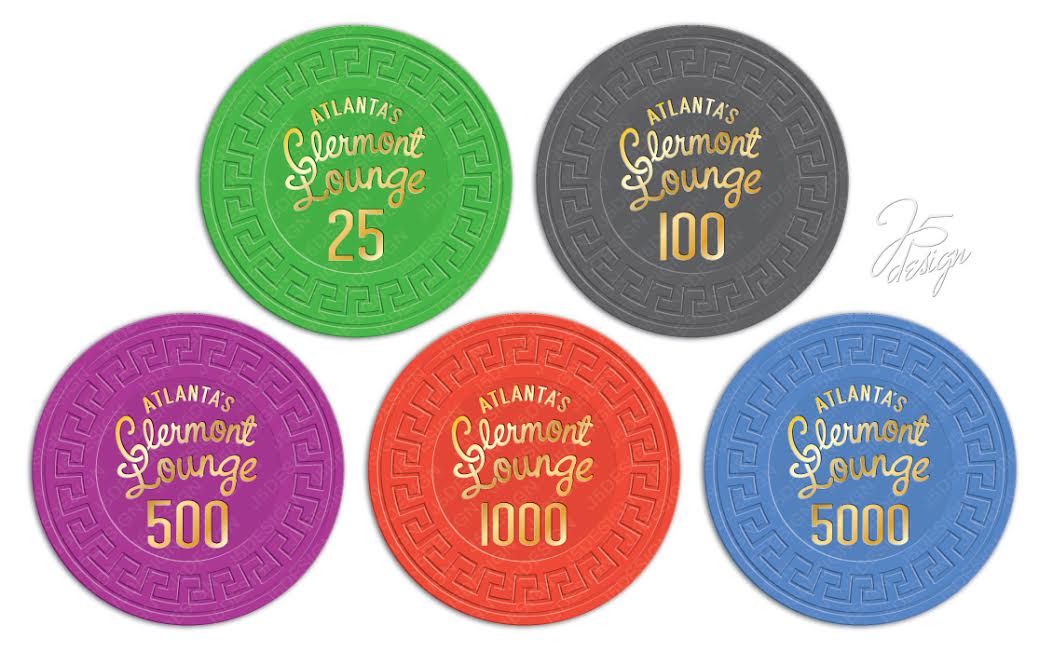

I need to talk to my die vendor to update but it should be in the $15/die range...and cheaper the more dies you get.

Cost per chip....$0.25 to stamp and $0.05 to scrape

If you have any questions feel free to ask...just be patient for a response!!