Back in July I started working on the second poker table I've ever built.

Objectives:

> 6-7 person, squeeze in 8, for small games in my small apartment

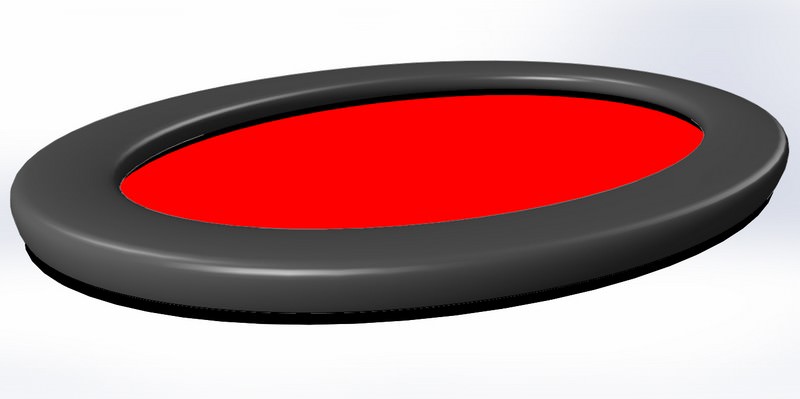

> ellipse shaped - my favorite table design

> 3/4" raised rail because I like the look and ergonomics

> sturdy folding legs - something a bit nicer than standard banquet table legs

> plain SSC / vinyl rail

> fully disassemble-able for future layout upgrade and/or rail re-upholstering

> trim ring with decorative nails beneath the rail, for a nice visual touch

Figured it would take me a month or two to complete - here I am in late October just wrapping it up. I've waited til now to post a build thread because - frankly - I've been afraid all along that the result would not be worthy of posting.

Fortunately, it turned out pretty decent given my circumstances.

This build was done in a driveway, 100' from the nearest outlet, with materials transported in a 2-dr coupe, with sub-par tools** lugged down three flights of stairs in a cardboard box for the odd few hours I could squeeze in every weekend.

This thread is intended to provide some inspiration for those who think they may not have the resources to embark on a build. Take your time, execute each step to the best of your ability, learn from the missteps, and stick with it - it can be done!

I made plenty of mistakes in both design and execution along the way and intend to share the wisdom I've gained in realizing them.

So let's dig in.....

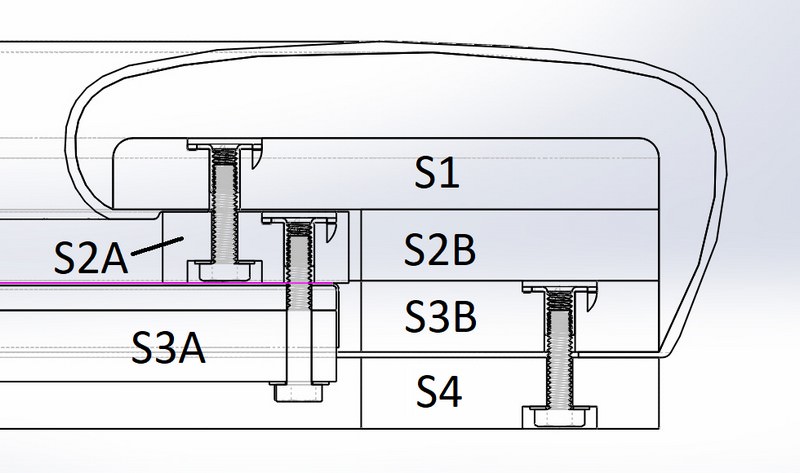

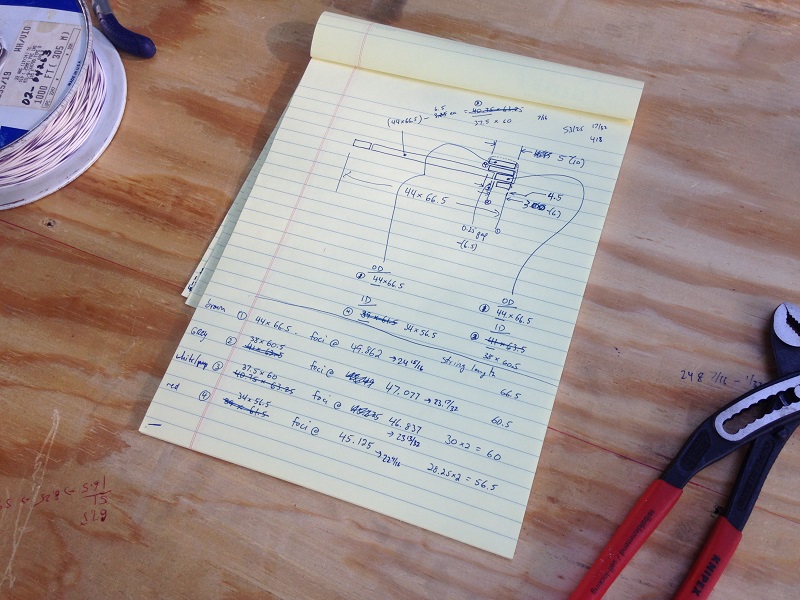

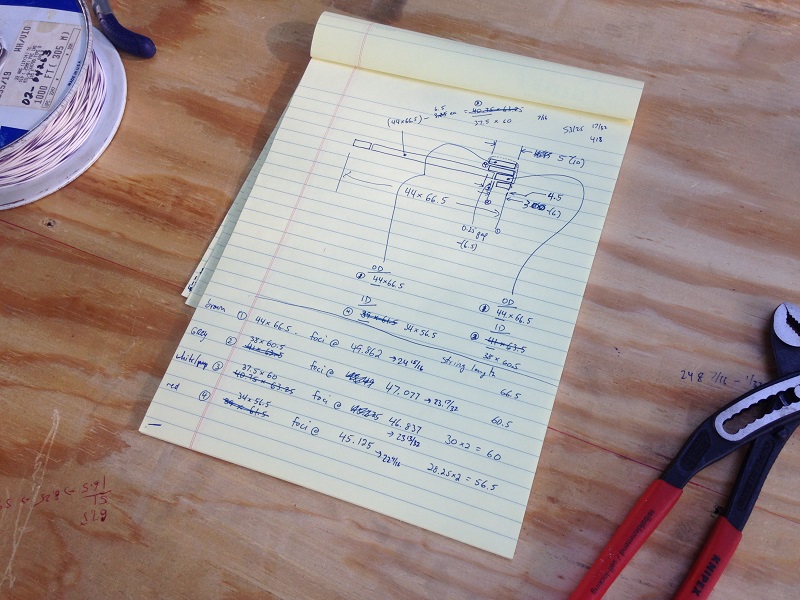

I started with a rough cross section sketch and some calculations for placing the ellipse foci:

(**Okay, so those Knipex slipjaws are badass. Most of the other tools in this build... not so much.)

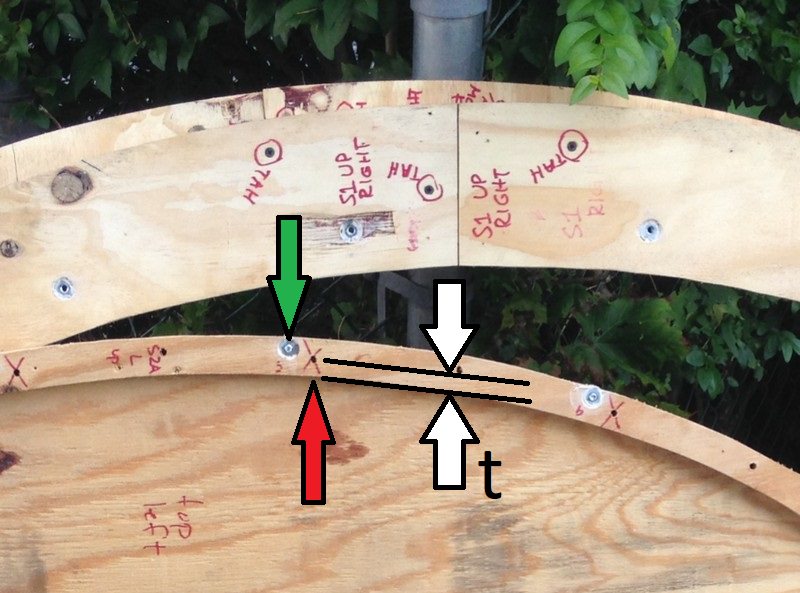

Laying out some ellipses to cut the rail. I had previously rough-cut the plywood to shape so I could shoehorn it into my car. All the plywood I used was free scrap.

I thought this wire would be pretty resistant to stretching. It wasn't. This caused some asymmetries that would plague me through the whole build.

Using the best available jigsaw blades and taking your time on the cuts really helps make up for a shitty jigsaw. Note how I made two cuts to replicate the 1/4" kerf that a router would leave you. This really helped fitting the playing surface to the rail pieces later on.

Also note how I left "tabs" connecting segments of cuts. This was a very helpful technique as I was able to make the majority of the cuts without the center piece wanting to drop out and. I cut off the tabs as a last step only after going all the way around with the rest of the cuts.

And a few other pieces cut and ready to go. The piece on top is the upper rail surface. Later on I would end up cutting it right in half.

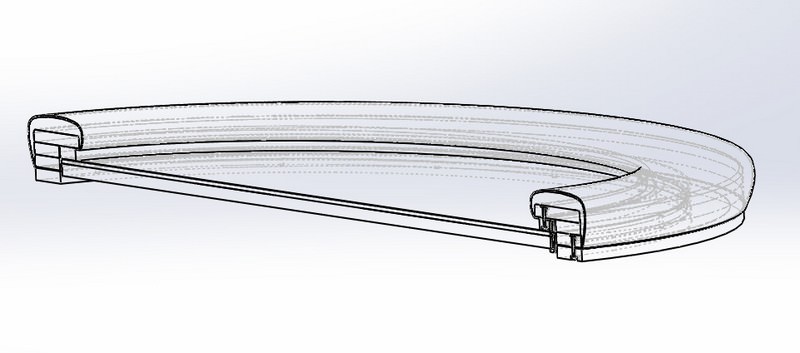

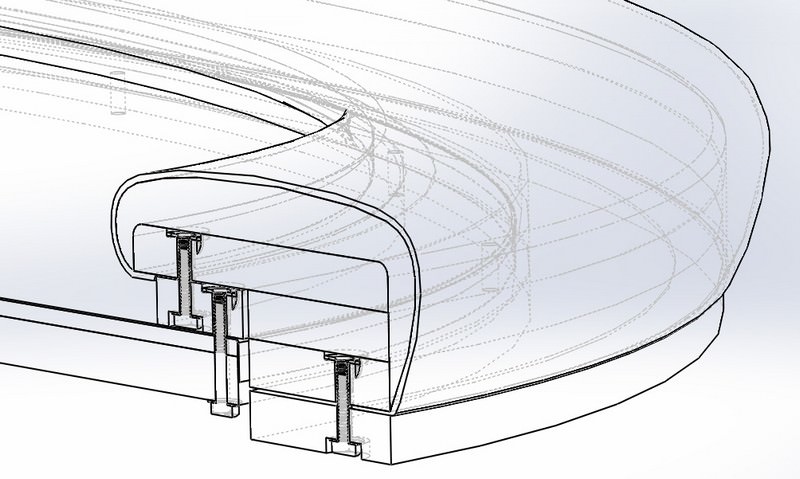

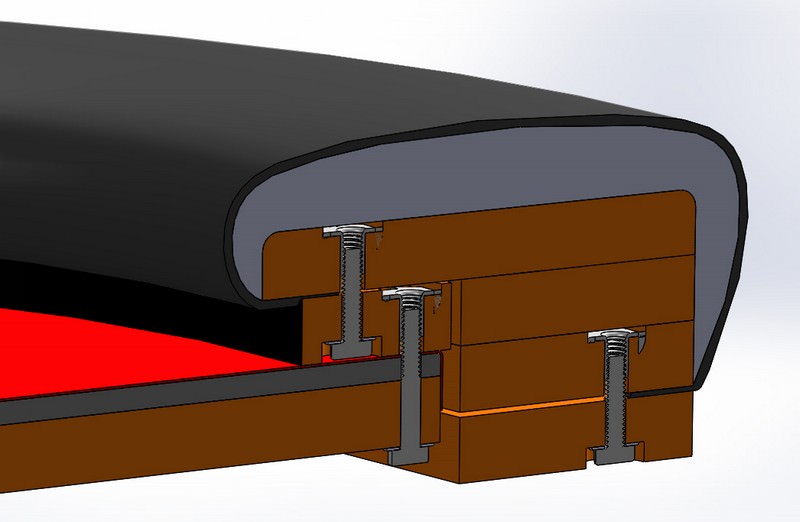

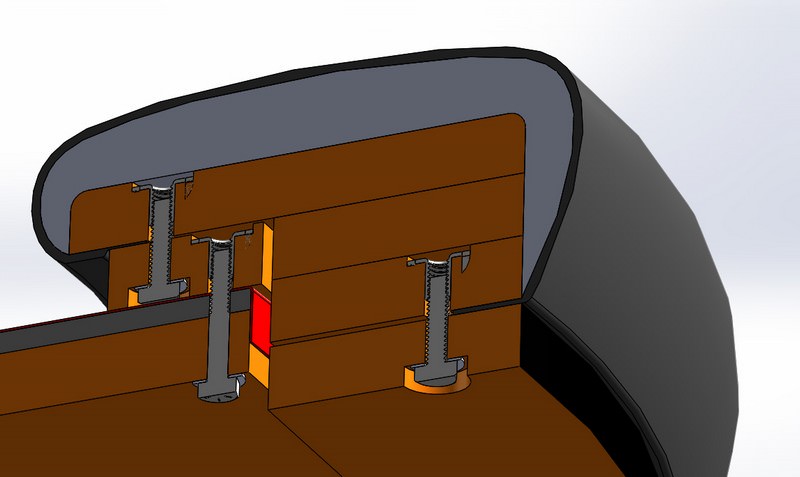

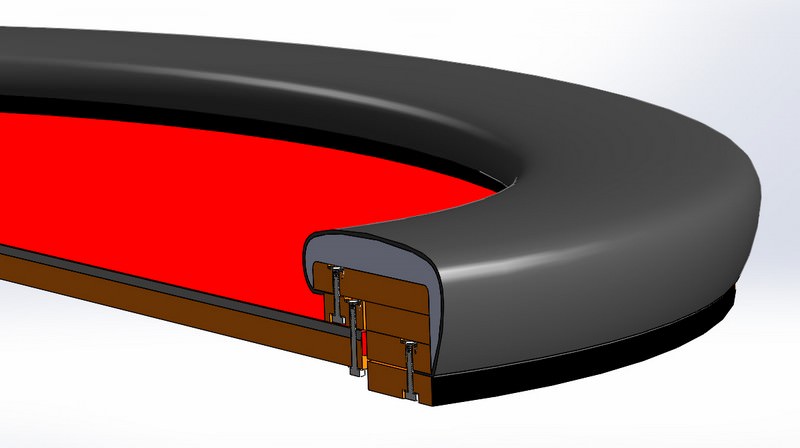

Once I locate all my currently misplaced sketches - I will go through the design and cross section layout in a little more detail so that you can follow along what's what in future pictures. The raised rail added more complexity than I bargain for!

Objectives:

> 6-7 person, squeeze in 8, for small games in my small apartment

> ellipse shaped - my favorite table design

> 3/4" raised rail because I like the look and ergonomics

> sturdy folding legs - something a bit nicer than standard banquet table legs

> plain SSC / vinyl rail

> fully disassemble-able for future layout upgrade and/or rail re-upholstering

> trim ring with decorative nails beneath the rail, for a nice visual touch

Figured it would take me a month or two to complete - here I am in late October just wrapping it up. I've waited til now to post a build thread because - frankly - I've been afraid all along that the result would not be worthy of posting.

Fortunately, it turned out pretty decent given my circumstances.

This build was done in a driveway, 100' from the nearest outlet, with materials transported in a 2-dr coupe, with sub-par tools** lugged down three flights of stairs in a cardboard box for the odd few hours I could squeeze in every weekend.

This thread is intended to provide some inspiration for those who think they may not have the resources to embark on a build. Take your time, execute each step to the best of your ability, learn from the missteps, and stick with it - it can be done!

I made plenty of mistakes in both design and execution along the way and intend to share the wisdom I've gained in realizing them.

So let's dig in.....

I started with a rough cross section sketch and some calculations for placing the ellipse foci:

(**Okay, so those Knipex slipjaws are badass. Most of the other tools in this build... not so much.)

Laying out some ellipses to cut the rail. I had previously rough-cut the plywood to shape so I could shoehorn it into my car. All the plywood I used was free scrap.

I thought this wire would be pretty resistant to stretching. It wasn't. This caused some asymmetries that would plague me through the whole build.

Using the best available jigsaw blades and taking your time on the cuts really helps make up for a shitty jigsaw. Note how I made two cuts to replicate the 1/4" kerf that a router would leave you. This really helped fitting the playing surface to the rail pieces later on.

Also note how I left "tabs" connecting segments of cuts. This was a very helpful technique as I was able to make the majority of the cuts without the center piece wanting to drop out and. I cut off the tabs as a last step only after going all the way around with the rest of the cuts.

And a few other pieces cut and ready to go. The piece on top is the upper rail surface. Later on I would end up cutting it right in half.

Once I locate all my currently misplaced sketches - I will go through the design and cross section layout in a little more detail so that you can follow along what's what in future pictures. The raised rail added more complexity than I bargain for!